Vibratory screens or peneira vibratoria are used in many industries such as mining, agriculture and recycling. These machines help in the sorting and separation of the materials by size and other physical attributes which is important in the processing and quality control. The connection with other equipment, including the triturador de pedras (stone crusher), improves these processes, which is why vibratory screens are essential in operational processes. This article focuses on the different uses of vibratory screens in sorting materials.

Enhanced Sorting Accuracy

Vibratory screens are used for high precision sorting where the material is shaken to sort it according to size. These screens can be adjusted to the required degree of precision to allow only the right size of materials to pass through while the larger aggregates are either crushed further or discarded. This accuracy is important in industries such as mining where the quality of the output determines the efficiency of the subsequent processes such as mineral extraction.

Reduction in Operational Costs

The use of vibratory screens in sorting can greatly help in cutting down the expenses. These screens help in sorting materials into different sizes in a more efficient manner and in the process, they cut out the time and effort that would otherwise be required in sorting the materials manually as well as the wastage of valuable materials. Also, by making sure that only right size materials get to the next level of processing, for instance a triturador de pedras, energy and wear on equipment are conserved.

Increased Productivity

This paper concludes that the application of peneira vibratoria in material handling operations results in an improvement in the general productivity. These screens can handle a large amount of material at one time and can keep a constant stream of sorted material. This continuous operation is essential in areas such as construction and mining where the material requirement is high and any interruption can cause a lot of losses.

Versatility in Application

Vibratory screens can be used in any operation and with any material that is to be screened. They can be designed to suit the nature of the material being processed ranging from ores and minerals in the mining industries to agricultural products and waste recycling. This versatility makes them an invaluable asset in various industries, all of which can leverage the unique strengths of vibratory screening technology.

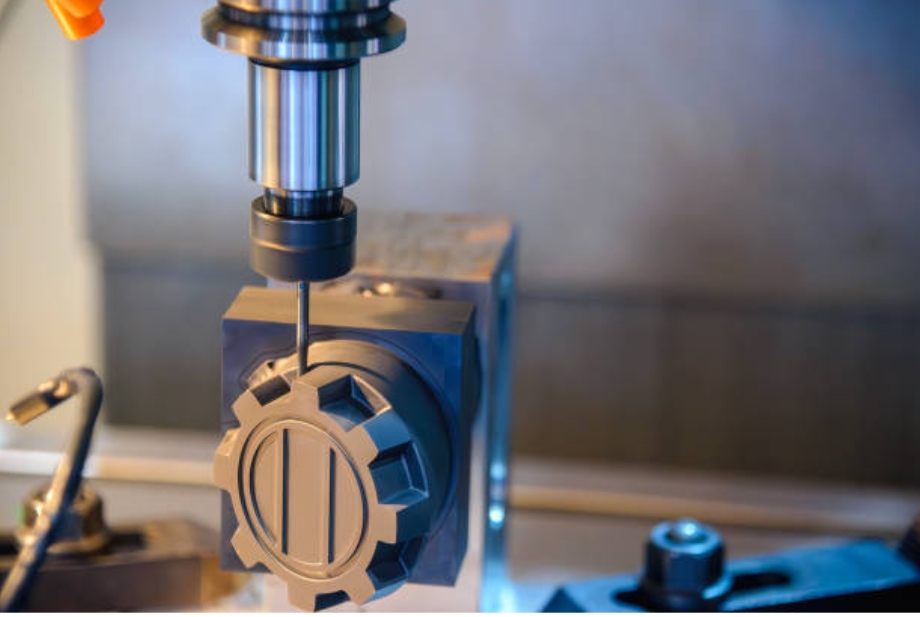

Integration with Stone Crushers

When a peneira vibratoria is combined with a triturador de pedras, the crushing and sorting line becomes very efficient. This arrangement enables the reprocessing of oversized materials which are returned to the stone crusher by the vibratory screen without delay. This closed-loop system also optimizes the use of materials and at the same time, minimizes the time wasted and increases the quality of the output.

Vibratory screens are used in industries to sort and classify materials and are very important in the industries. They are able to sort materials according to size and are compatible with other important machines such as triturador de pedras in the current industrial processes. Thus, the use of vibratory screens contributes to the improvement of sorting accuracy, reduction of operational costs, and increase in productivity, which in turn allows industries to achieve their processing and quality objectives.