The automotive industry is abuzz with excitement as electric vehicle (EV) manufacturing takes center stage, heralding a new era of transportation. No longer just a niche market, electric vehicles are rapidly establishing themselves as the future of the auto sector. This transformation is revolutionizing the design, production, and powering of cars, reshaping the entire landscape of vehicle manufacturing.

So, what’s driving this change, and how is it reshaping the auto industry? From cutting-edge battery technologies to streamlined production processes, EV manufacturing is making significant waves. Companies like ECD Auto Design are exploring innovative ways to integrate electric drivetrains into classic models, effectively blending the charm of traditional designs with modern technology. This evolution not only emphasizes sustainability but also honors automotive heritage.

The Rise of Electric Vehicle Manufacturing

The electric vehicle market has seen remarkable growth in recent years. In 2023, global EV sales soared to nearly 14 million, reflecting a 35% increase from the previous year. This surge has significantly expanded the global electric fleet, which reached 40 million vehicles in 2023, with China, Europe, and the United States accounting for approximately 95% of all EV sales.

The variety of electric car models available to consumers has also grown, with 590 options in 2023—a number projected to reach 1,000 by 2028. Despite challenges like the phase-out of purchase subsidies in certain regions, the EV market continues to flourish. Governments around the world are prioritizing the expansion of charging infrastructure, recognizing its essential role in sustaining the EV revolution.

As the industry evolves, both traditional manufacturers and custom builders must rethink their design and engineering strategies. The integration of electric drivetrains presents opportunities to reimagine classic designs, enabling projects that pay homage to iconic vehicles while embracing cutting-edge technology. This progression suggests a future where electric and classic vehicles can coexist, providing enthusiasts with performance and efficiency without compromising the character of their beloved rides.

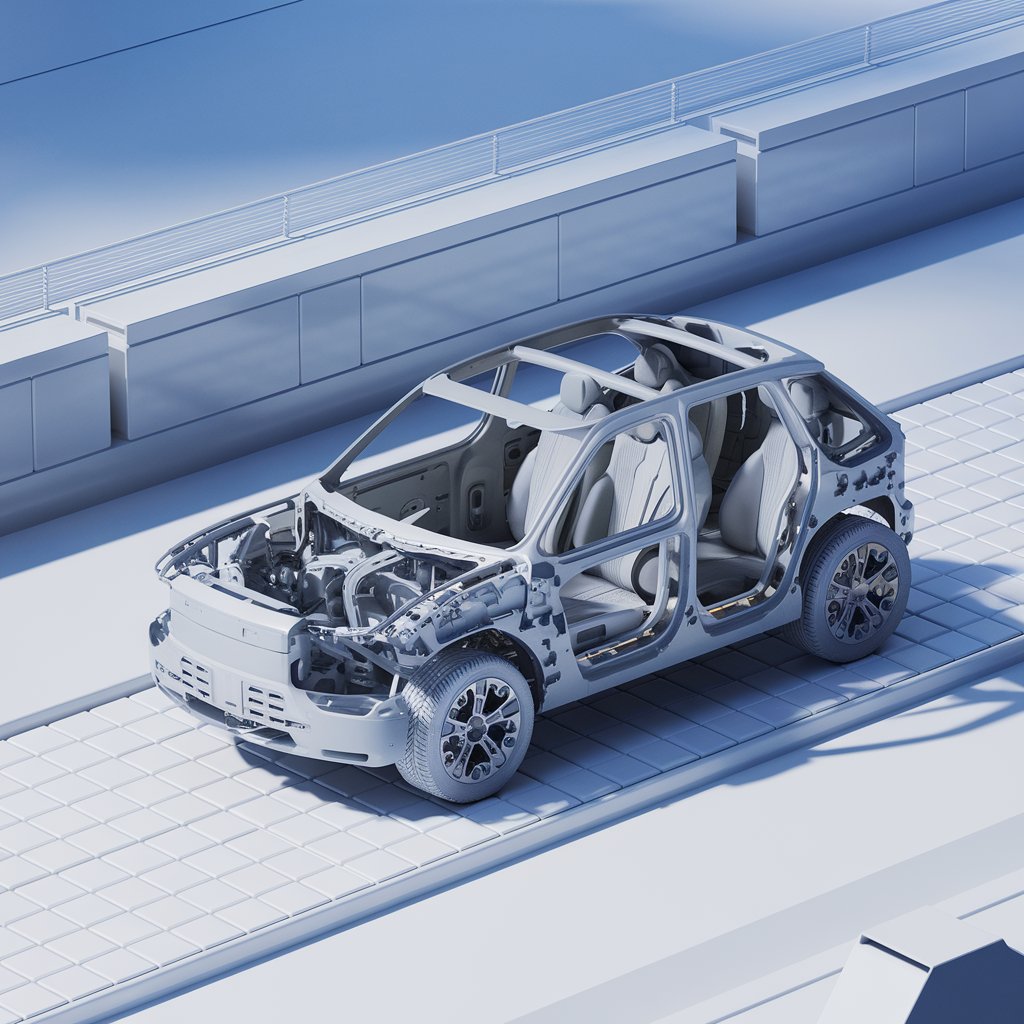

Changes in Vehicle Design and Components

The shift to electric vehicles has ignited a revolution in vehicle design and components. EVs necessitate unique parts such as batteries and drive units, resulting in a more straightforward assembly process compared to traditional vehicles. The focus has transitioned from protecting engines to safeguarding batteries, prompting automotive designers and engineers to rethink EV design with a strong emphasis on aerodynamics, weight reduction, and energy efficiency.

A key modification is the underbody, now featuring an aerodynamically designed full belly pan that houses the battery pack. The vehicle’s structure, known as the “space frame,” is crafted from strong, lightweight aluminum. Additionally, body panels are increasingly made from lightweight aluminum or impact-resistant composite plastics, both of which are recyclable materials. These changes aim to minimize weight while upholding high strength and safety standards.

Transformations in Production Processes

The transition to electric vehicle manufacturing has fundamentally altered production processes. Automation plays a critical role in this transformation, enhancing efficiency and productivity while ensuring consistency. For instance, Tesla’s Gigafactory 1 in Nevada is highly automated, capable of producing batteries for up to 500,000 vehicles annually. Similarly, Volkswagen’s Zwickau plant in Germany operates entirely on automation, producing up to 330,000 EVs each year.

Robotic automation is employed throughout various stages of the EV supply chain, including assembly, painting, and warehouse operations. This approach not only streamlines the manufacturing process but also reduces the likelihood of human error. Advanced technologies like machine learning and AI are being leveraged to optimize production, forecast demand, schedule operations, and manage inventory levels. For example, Toyota utilizes AI to enhance production efficiency at its Takaoka plant in Japan.

Embracing the Electric Future

The transformation of the automotive industry through EV manufacturing is not merely a trend; it represents a fundamental shift that influences vehicle design, production processes, and the overall landscape of transportation. This evolution affects every aspect of the automotive world, from rising global EV sales to groundbreaking changes in vehicle components and assembly methods.

Looking ahead, it is clear that the EV revolution is here to stay. The industry’s commitment to electric vehicles is driving innovation and expanding the boundaries of what’s possible in car design and manufacturing. This transformation holds the potential to create a more sustainable and efficient future for transportation. As EV technology continues to advance, we can anticipate even more exciting developments that will redefine how we move and live.

This version enhances clarity, flow, and engagement while maintaining a balanced focus on the broader changes in the industry. Let me know if you’d like any further adjustments!