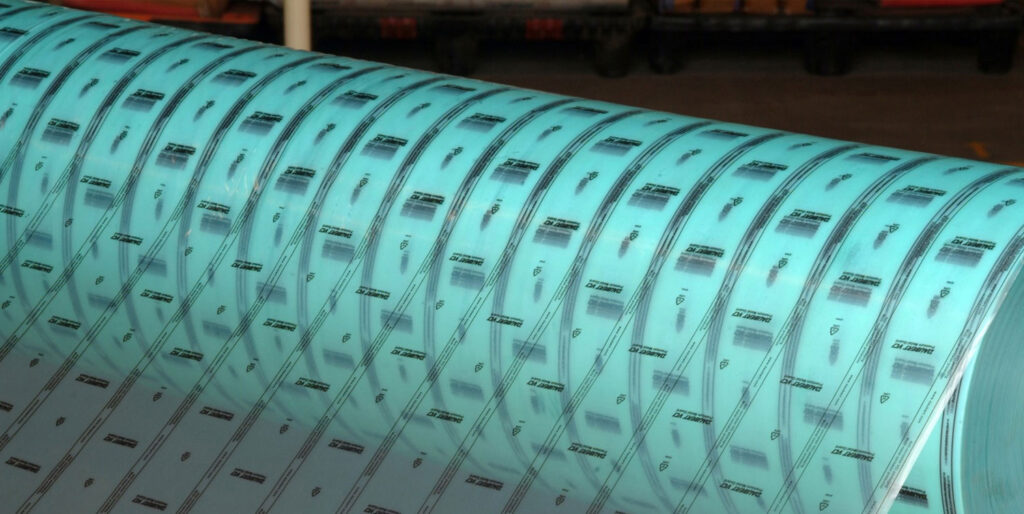

VCI Stretch Film offers highly effective corrosion protection for a wide range of industries, ensuring that metal products, parts, and machinery are shielded from rust and oxidation during storage, transportation, and handling. Whether used with Machine Stretch Film systems or applied manually with Hand Stretch Film, VCI Stretch Film provides versatile and reliable protection. Below are some of the most common applications of VCI Stretch Film:

VCI Stretch Film for Automotive Parts

The automotive industry is one of the largest users of VCI Stretch Film due to its ability to protect metal components from rust and corrosion, which is a common issue during storage and transport. Car parts, engines, and other automotive assemblies are particularly vulnerable to environmental elements like moisture, salt, and humidity, all of which can lead to rusting and deterioration.

By using VCI Stretch Film, automotive manufacturers, suppliers, and distributors can ensure that metal parts stay rust-free throughout the supply chain. The VCI embedded in the film releases protective vapors that create an invisible molecular barrier on metal surfaces, preventing oxidation. Whether wrapped around engine blocks, exhaust systems, brake parts, or chassis components, VCI Stretch Film helps automotive companies maintain product integrity and quality until the parts are installed in vehicles or sold to end users.

Furthermore, the film provides a clean and non-oily alternative to traditional rust prevention methods, such as oil coatings, which can be messy and labor-intensive. Machine Stretch Film systems are also used in automotive warehouses and production lines to wrap large quantities of metal parts quickly and efficiently, ensuring consistent protection throughout the packaging process. Whether applied manually with Hand Stretch Film or automatically with machine systems, VCI Stretch Film ensures that metal parts remain free of rust and ready for use or shipment.

Protecting Large Machinery and Components

In industries like manufacturing, construction, and heavy machinery, VCI Stretch Film plays a crucial role in protecting large, heavy parts during transportation and long-term storage. Whether it’s large machinery components, construction equipment parts, or industrial tools, these products are often exposed to harsh environmental conditions during shipping and can easily succumb to corrosion if not properly protected.

VCI Stretch Film offers a cost-effective solution for preserving the quality of these large items. The stretch film adheres tightly to the surface, preventing moisture, dust, and contaminants from coming into contact with the metal. Additionally, the film’s VCI vapors provide internal protection to hard-to-reach areas, such as cracks and crevices, that are difficult to shield with other forms of packaging.

In industries where machinery and equipment are stored for extended periods before use, the protective properties of VCI Stretch Film ensure that the products remain in optimal condition. The film’s durability and resistance to punctures and tears make it ideal for wrapping large and heavy items without worrying about the film breaking or losing its protective properties during transit or storage.

VCI Stretch Film in Warehousing and Distribution

For warehouses and distribution centers, VCI Stretch Film provides an invaluable solution for maintaining the integrity of metal goods during storage and transport. Many warehouses deal with metal parts, tools, and components that need to be stored for extended periods before reaching their end users. During this time, the risk of corrosion from environmental factors, such as humidity and moisture, is high.

VCI Stretch Film helps warehouses protect these products by providing a reliable and cost-effective barrier against rust and oxidation. When products are wrapped in VCI Stretch Film, the VCI compounds release vapors that form a protective layer on the metal surface, ensuring that rust doesn’t develop while the product is stored or in transit. This protection extends to all types of metal goods, including automotive parts, industrial tools, and machinery components.

By using VCI Stretch Film, warehouses can ensure that products are delivered to customers in perfect condition, without the risk of rust or corrosion. This also improves overall inventory management, as metal goods can be stored for longer periods without the need for additional rust-prevention treatments. The transparency of the VCI Stretch Film makes it easy to inspect and track products without removing the protective wrap, streamlining the handling process in busy distribution environments.

Additional Applications

Beyond the automotive, manufacturing, and warehousing industries, VCI Stretch Film is also widely used in sectors like aerospace, electronics, and marine for protecting metal components from corrosion during storage and shipping. The versatility of VCI Stretch Film, combined with its ability to conform tightly around products, makes it suitable for irregularly shaped items and large volumes of goods.

With its easy application, cost-effectiveness, and environmentally friendly nature, VCI Stretch Film has become a go-to solution for industries seeking reliable, efficient, and sustainable packaging to protect metal products from corrosion. Whether used for wrapping small components by hand or large machinery with automated machines, VCI Stretch Film provides a robust solution that ensures products stay rust-free and in prime condition until they reach their end users.