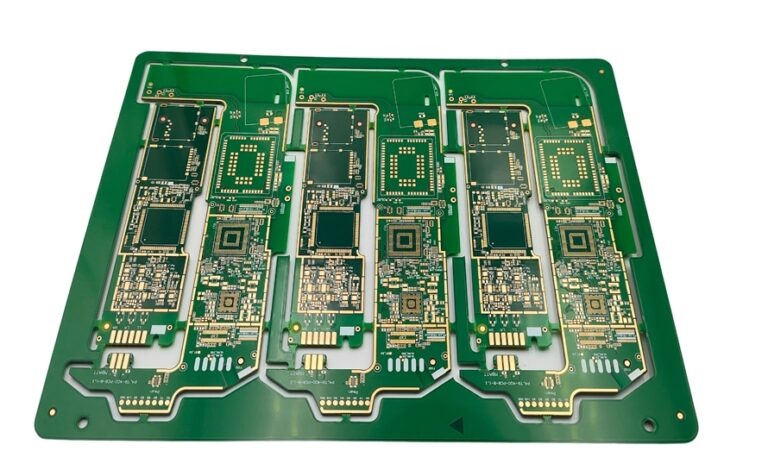

Who is an HDI PCB supplier? An HDI PCB manufacturer can be defined as a perfect firm responsible for producing high-density interconnect (HDI) printed circuit boards. These unique circuit boards house more circuits without expanding their physical space. They are used in different current applications such as mobile phones, tablets, and other instruments that need to be tiny and powerful.

Understanding the structure of HDI PCBs

HDI PCBs are not conventional boards. Instead, they come with very small holes and thin lines. Consequently, the hole space on the board is very large. The PCBs and phones, tablets, and other small-scale instruments use HDI technology to work.

Micro and buried vias are usually accepted as the supreme facilitators of what we wish to achieve. They are employed to bond the different layers of the circuit board with some of the smartest connection methods.

HDI PCBs are more complex to produce than regular PCBs. They need special devices and painstaking work. Therefore, choosing the most suitable HDI PCB manufacturer is critical.

Main Features of a Good HDI PCB Manufacturer

Advanced Technology

Great HDI PCB manufacturers must use up-to-date equipment and devices. These tiny different types of PCBs need unique machines to be drilled. Search for producers who talk about the automation of their factory and modern techniques.

The provider should have the potential to fabricate different kinds of HDI PCBs. This also includes boards with multiple layers and microvias. They should be able to use other components that best suit your HDI designs.

Quality Control

Quality is a prime concern for HDI PCBs. A good company will have very careful quality checks. Every board is expected to be checked for any malfunctions from the start. When looking for companies to assess, it might be recommended that you check whether they adhere to international quality standards, such that an ISO 9001 certificate is the best one to check.

The supplier should use the best test devices. This would help them to pinpoint boards showing problems. Besides, they should have a well-defined procedure for resolving the issues.

Ask them about what actions they take in quality control. An efficient manufacturer will not only be glad to tell you how the guarantee of quality is achieved but also send you evaluation reports for their boards.

Experience and Expertise

Creating HDI circuit boards is a tough task that experienced specialists can only do. This is because PCBs are a very delicate area of the electronics sector, which is highly technology-oriented. So try to find a company that specializes in HDI PCBs and has an experienced trouble-shooting team.

One good producer is going to sit with you and solve design problems. Besides, they can also provide propositions for better ways to create your layout. It is a long-term investment that usually saves both time and dime.

The function of a Printed Circuit Board Fabricator

Printed Circuit Board Manufacturer is one of the major players in the electronics industry. They prepare the electric circuits on which all the components are mounted, which are then completely introduced into electronic devices. These producers operate from simple conventional PCBs to the latest generation of HDI PCBs.

One way to choose the right HDI PCB manufacturer is to reflect on their performance in making and designing other kinds of printed circuit boards. With this broader experience, they possess a higher potential to benefit you more.

Customer Service and Support

Communication

Effective communication is the key to success when dealing with an organization fabricating an HDI PCB. Seek a company that has promptly answered all my questions and requests. They should be able to articulate the technical side so that everybody can comprehend the information.

Those making PCBs should have a dedicated customer support team. This organization can assist you with any complaints during production. They should also be able to notify you about your order.

Check to see if they have the means for communication – through email, phone, and online chat. That way, they can stay connected with you as directly as possible.

Design Support

The HDI PCB design could result in the issue of complexity. A good supplier is an organization that has design support services. This might also involve the examination of the designs for their manufacturability and providing suggestions to improve the design.

Choose a manufacturer with a design engineering team. They can resolve issues with design and make your HDI PCB layout be in its best form. This assistance can result in a successful project at the end of the day, especially if it is complex.

Refer to their design review process. A deep review of the design process is key when the designer can identify and eliminate potential errors and discrepancies. This, in turn, saves time and money from problems that arise during production.

Production Capabilities

Capacity

Examine the production capacity of the manufacturer. They should be able to produce your evaluated order regardless of whether it is large or small. Proceed with inquiries about their minimum order quantity and capacity to increase output when necessary.

Look for a manufacturer that currently equips the factory with flexible production lines. This is what enables them to reconfigure for many order scales and types. The efficient outlay of this factory also allows this manufacturer to carry out rushes fast and efficiently.

Materials

HDI PCBs commonly need exotic materials. The first thing that should be on the checklist is a proper supplier with access to all PCB materials. The list goes on as the material is phased to the high-performance heat-conducting material suitable for HDI designs.

Inquire them about the sources from which they got the materials. The good supplier deals with reliable suppliers and hence obtains high-quality materials. For the particular design of your HDI PCB, they should also be able to give you an idea of the best materials they have in stock.

Conclusion

Selecting the appropriate HDI PCB supplier is a very influential element. You could search for a firm that is really into automation, looks forward to having zero quality defects, offers great customer support, and is one with HDI experience and expertise.

It is also important to check their production capacities and the materials they are using. Certification and compliance with the manufacturers’ regulations are paramount. A reliable manufacturer will be an ally in your HDI PCB projects.