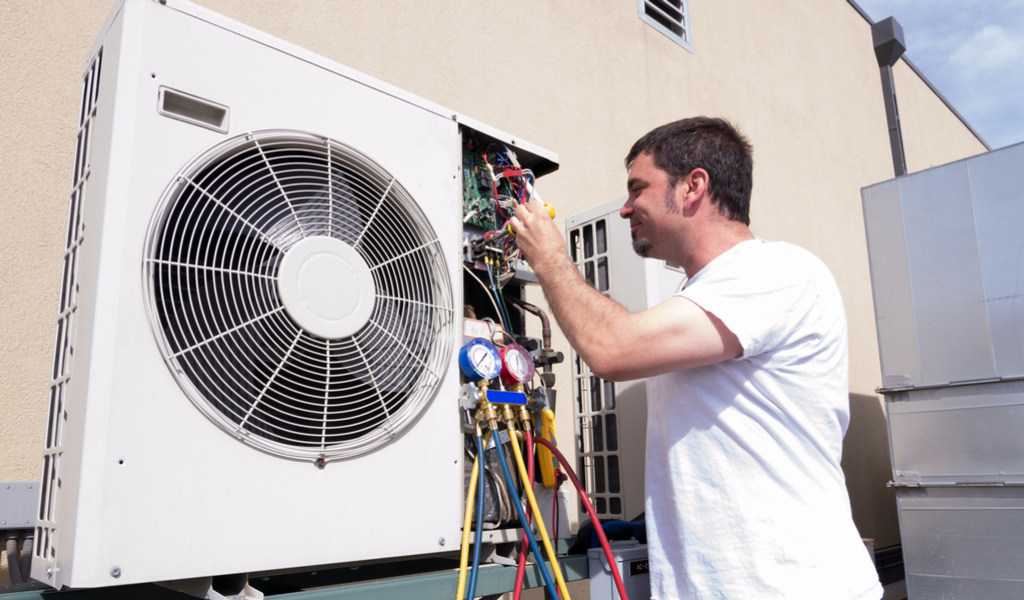

The operational integrity of air conditioning systems hinges significantly on the quality of their electrical components, with run capacitors representing a critical element that directly influences energy efficiency, compressor longevity, and overall system reliability. Professional HVAC technicians increasingly recognize that capacitor selection extends beyond basic microfarad ratings and voltage specifications to encompass performance characteristics that determine real-world operational benefits. Sourcing reliable AC capacitors at Wagner Online provides significant advantages through their stringent component testing protocols and specialized inventory selection focused on HVAC applications. Industry data from the Air Conditioning, Heating, and Refrigeration Institute indicates that approximately 60% of emergency service calls during peak cooling seasons involve electrical component failures, with capacitor degradation representing the predominant issue due to suboptimal replacement component selection during previous maintenance.

Superior Voltage Handling Characteristics

Industrial-grade capacitors designed specifically for HVAC applications demonstrate significantly different voltage handling capabilities compared to general-purpose capacitors with identical nominal ratings. This distinction becomes particularly evident during operational conditions involving voltage fluctuations and surge events.

The capacitors available through specialized suppliers undergo enhanced testing for voltage tolerance beyond standard safety certification requirements. While residential capacitors typically carry 370V or 440V ratings, their actual performance during transient events varies dramatically based on internal construction. Premium capacitors utilize thicker dielectric materials with controlled material consistency that provides substantially higher breakdown voltages—typically 30-50% above their nominal ratings.

Sustained overvoltage capability represents another critical differentiation factor, with higher-quality capacitors maintaining integrity during extended periods of elevated line voltage that commonly occur during utility grid switching operations. This enhanced margin prevents the progressive dielectric degradation that ultimately leads to premature failure in standard-grade components exposed to identical conditions.

Temperature Stability and Environmental Durability

The operating environment for AC capacitors presents significant thermal challenges, with ambient temperatures inside condenser units frequently exceeding 60°C during peak cooling periods. This thermal stress directly impacts capacitor performance and lifespan through multiple degradation mechanisms.

Professional-grade capacitors employ specialized dielectric materials with significantly lower dissipation factors across wider temperature ranges. This characteristic reduces self-heating during operation, creating a beneficial cycle where lower internal temperatures further enhance performance stability. Testing data demonstrates that premium capacitors maintain capacitance values within ±5% across their specified temperature range, while standard components may exhibit variations exceeding ±20%.

Environmental protection systems represent another critical quality differentiator. Advanced capacitors utilize hermetic sealing technologies that prevent moisture ingress even during condensation cycles that naturally occur during system operation. This protection prevents the electrolyte degradation that progressively reduces capacitance in standard components, ultimately leading to compressor starting failures despite the capacitor appearing visually normal.

Enhanced Safety Features and Failure Mode Engineering

Capacitor failure modes significantly impact both system reliability and safety, with important distinctions between standard and premium components that extend beyond basic operational parameters.

High-quality capacitors incorporate engineered failure modes designed to minimize collateral damage when end-of-life conditions occur. Advanced pressure-sensitive disconnection systems interrupt internal connections before catastrophic case rupture can occur, preventing the release of dielectric materials that may damage surrounding components or create fire hazards.

Internal construction techniques, particularly in metalized polypropylene designs, implement self-healing capabilities that isolate small dielectric breakdown points without complete functional failure. This characteristic allows the capacitor to continue functioning at slightly reduced capacitance rather than failing completely, providing additional operating time until scheduled maintenance rather than causing immediate system shutdown.