In the realm of industrial machinery and operations, components that may appear inconsequential at first glance can have profound effects on process efficiency, overall productivity, and the reliability of equipment. Among such components, Kipp Spring Plungers stand out as essential elements for a vast range of applications. The significance of these parts in facilitating optimal performance within industrial settings cannot be understated. This article aims to elucidate the pivotal role Kipp Spring Plungers play in enhancing industrial efficiency.

Understanding Kipp Spring Plungers

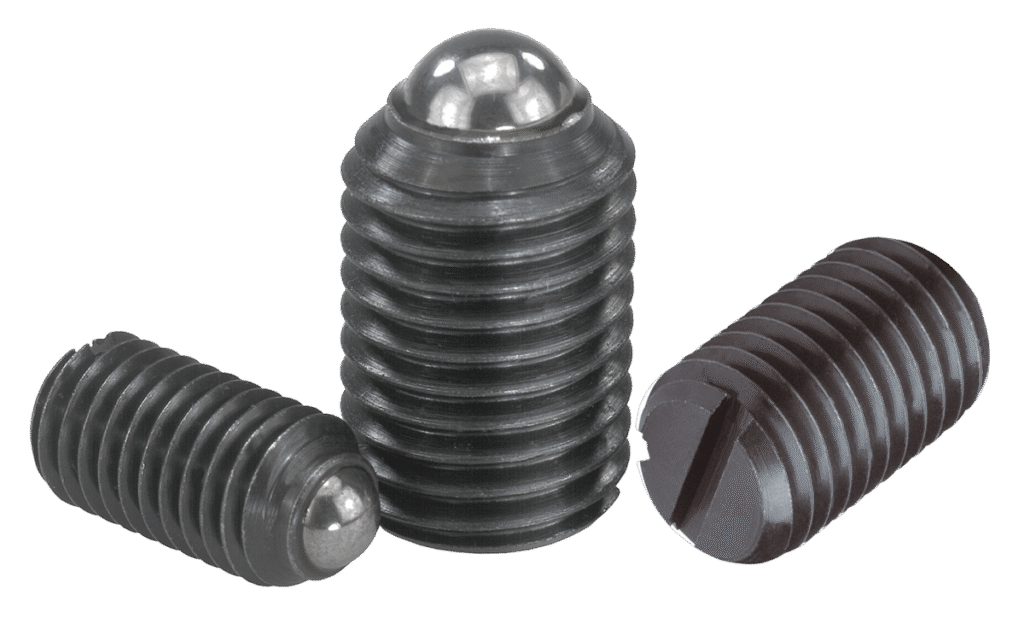

Kipp Spring Plungers are precision components designed to apply controlled forces using a spring mechanism. Integrally, these tools are used in positioning, securing, and clamping operations across various sectors. The utility of spring plungers in machinery is significant due to their simple yet effective design, making them indispensable in providing an optimal balance between force and movement within assemblies.

The Integral Role in Industrial Machinery

Industrial systems and machinery oftentimes require components that maintain position and apply consistent force—tasks for which spring plungers are perfectly suited. They are utilised in a range of applications, from serving as simple indexing devices to more complex roles in loading and clamping mechanisms. The reliability and precision of Maxiloc Kipp Products in these applications make them a go-to solution for many engineers and technicians.

Advantages in Production and Assembly

The implementation of Kipp Spring Plungers on production lines can lead to numerous benefits. For instance, these components enable swift and accurate positioning of parts, which reduces the time spent on manual adjustments. The consequent enhancements in speed and precision during the assembly process greatly uplift production rates and diminish the likelihood of errors.

Cost-Effectiveness and Maintenance

From a financial perspective, the adoption of Kipp Spring Plungers can lead to cost reductions. Their durability and low need for maintenance mean that machinery can operate for longer periods without downtime, which is invariably linked to cost savings. Moreover, the simplicity of replacing these components, when necessary, minimises repair and maintenance expenses.

Safety and Consistency

A paramount concern in industrial environments is safety, and well-designed components contribute significantly to safer work conditions. Kipp Spring Plungers offer consistent performance, which allows machinery to operate predictably, reducing the risk of accidents caused by component failure or erratic operation.

Customisability and Versatility

One of the standout attributes of Kipp Spring Plungers, particularly those provided by Maxiloc, is the range of customisation options available. Different sizes, materials, and force capacities ensure that there is a suitable plunger for almost any industrial application. This versatility extends the utility of Maxiloc Operating Parts across various industries, from automotive to electronics.

Enhancing Product Quality

Quality assurance in product manufacturing is tightly linked to the consistency and precision of the machinery used. By utilising reliable Kipp Spring Plungers, manufacturers can ensure that their products meet stringent quality standards by achieving uniformity in production processes.

Reducing Wear and Tear

Another substantial benefit lies in reducing wear and tear on machinery. Spring plungers absorb and exert forces in a controlled manner, helping to prevent damage and extend the lifespan of other machine components that might otherwise experience undue stress.

Applications with High Demand for Reliability

High-precision industries, such as aerospace and medical technology, require components with unwavering reliability. Kipp Spring Plungers offer the assurance needed for applications where a failure could have significant repercussions. Sectors like these depend on the performance that Kipp components provide to maintain high quality and safety standards.

Innovation in Design

Innovations in the design and manufacturing of Kipp Spring Plungers have led to enhancements that increase their applications and efficiency. Technological advancements continue to refine these components to meet the evolving demands of modern machinery and industrial processes.

Environmental Impact

Additionally, the sustainability of industrial operations is increasingly important. Efficient and durable components such as Kipp Spring Plungers contribute to a reduction in waste and energy consumption by minimising the need for frequent replacements and maintenance.

Conclusion: A Key to Industrial Progress

In conclusion, the seemingly simple Kipp Spring Plunger is a testament to the idea that the smallest parts can have a considerable impact. Through their ability to streamline processes, enhance safety, and ensure consistent product quality, Kipp Spring Plungers are integral to industrial efficiency. As manufacturers continue to strive for optimisation and innovation, the venerable spring plunger will undoubtedly remain a staple in the backbone of industry, silently driving progress through its precise application of force and movement.

Kipp’s dedication to quality and Maxiloc’s commitment to providing an expansive range of Kipp products ensure that no matter the application, there is a reliable, efficient solution at hand. It is the embodiment of impactful design in machine operations, which, though humble in stature, plays a colossal role in the advancement of industrial capabilities.