Some packaging feels like a hurdle. You’ve probably seen boxes sealed like a vault, impossible to open without scissors, knives, or frustration. It might look secure, but at what cost? When packaging becomes a battle, the experience around your product suffers.

With shipping security under the spotlight, many businesses are tightening packaging protocols. And yes, tamper-evident designs are necessary. But striking a balance between security and ease of access isn’t always straightforward. You’re trying to protect what’s inside without making the customer experience feel like an afterthought.

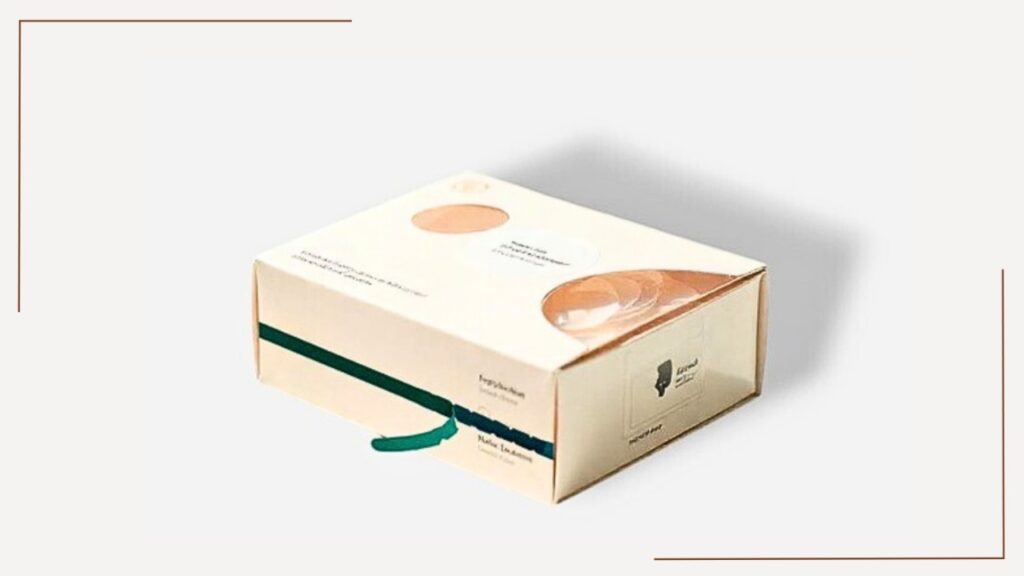

That’s where adhesive tear strip designs step in. They’re practical answers to a common problem. They reduce tampering risks, speed up the unpacking process, and keep the box looking clean and professional. Especially when integrated into custom mailer boxes, they add value without overcomplicating things.

This article will explore whether secure packaging comes at the cost of user-friendliness and why tear-strip solutions might be the exception.

The Security Mandate

Security has become a packaging standard, not a bonus. You’re expected to deliver products in sealed, tamper-evident boxes that leave no room for doubt. Whether shipping high-value goods or everyday items, one broken seal can lead to returns, claims, and questions about your reliability.

Traditional sealing methods, like tapes, stickers, and reinforced flaps, don’t always hold up. They can be manipulated without leaving visible signs. That creates risk. And even when tampering is obvious, you’ve already lost time, product, and potentially a customer’s trust.

Adhesive tear strip mailer boxes designs help you regain control. They seal the box securely and break in a way that clearly shows if it’s been opened. It’s simple, but effective and far more consistent than tape or glue alone. When you build this into your custom mailer boxes, you make tamper protection part of the structure, not an afterthought.

Explore how product security and authentication can be integrated with custom rigid boxes here: (ADD LINK of https://docs.google.com/document/d/1PjFS9kvMqOQCSZFbhyQ8a67jubfAqGpmIGfgyVWDuBA/edit?tab=t.0)

This detail matters for regulated industries or sensitive items. It helps you meet packaging standards without needing extra steps in your workflow. Tear strips work well with custom boxes, especially branded printing and clean layouts.

Unlike third-party sealing tools, tear strips work seamlessly with your custom packaging design. They don’t disrupt branding or design flow; they give you a stronger, more secure end product.

When Convenience Takes a Hit

Opening a sealed box shouldn’t feel like unwrapping a puzzle. However, overly secure packaging often slows things down, especially when sharp tools or extra effort are needed to access the contents. This friction affects both your workflow and the person receiving the item.

Boxes that require scissors, blades, or force to open also increase the risk of damage. Product surfaces get scratched, and branded elements inside get torn. In high-volume handling, that kind of inconvenience turns into avoidable waste.

Adhesive tear strips remove that friction. One quick pull gives clean access while still keeping the package tamper-evident. This balance works without extra training or tools.

When built into custom mailer boxes, tear strips contribute to a smoother process. They help handlers work faster, allow recipients to open parcels without hassle, and keep things neat even when shipments scale up.

This small addition also supports custom packaging goals. The box opens cleanly without damaging design elements or structural integrity, which is helpful when presentation and protection need to work together.

Why are the Tear Strip Mailer Boxes the Middle Ground

Tear strips offer a functional solution to a long-standing packaging dilemma: keeping contents safe while smoothing the unboxing process. They don’t rely on secondary seals or tools. Once a strip is torn, there’s no hiding it. That simple break is a visual indicator that the package has been accessed, making it easier to detect tampering. This level of transparency builds confidence at every step, from warehouse checks to final delivery.

Traditional sealing methods like tape can be manipulated or re-applied without clear signs of disturbance. That leaves a gap in security, especially for shipments where chain-of-custody is a concern. Adhesive tear strips close that gap. Once opened, they cannot be resealed without leaving clear evidence. This makes them especially useful for handling electronics, health products, or any item that must reach its destination unscathed and intact.

Integrating the strip directly into custom mailer boxes creates a secure and clean packaging experience. There’s no compromise in structure or branding. The box retains strength during transit, and the opening mechanism doesn’t interfere with printed designs or finishes. It’s a built-in feature that serves multiple functions: security, convenience, and presentation, without additional materials or steps.

For industries where inspections are frequent, tear strips simplify the process. Packages can be checked without full unsealing. If the strip is intact, it signals that the contents are untouched. If broken, the package can be flagged immediately. This removes unnecessary re-packing, which often slows fulfilment and causes excess material use.

Ultimately, tear strips support the goals of custom packaging by offering protection that’s easy to monitor and manage. They balance both sides of the packaging equation: keeping goods safe and the process straightforward. It’s an upgrade that doesn’t demand trade-offs, only more innovative design.

Cost vs. Value Debate

Tear strip integration doesn’t need significant design changes. It works with most box styles, especially during the structural planning stage, and no extra inserts, layers, or secondary components are required.

Cost-wise, the increase is minimal compared to the benefit. Reducing returns, damaged packaging, or lost time at the unpacking stage offsets the added material and setup. When scaled properly, the value holds steady across different product lines.

Tear strips can align with branding and box layout in custom mailer boxes without disrupting the design. They don’t interfere with graphics, color schemes, or logo placements, which helps maintain a clean and consistent presentation.

Switching to tear strip versions is straightforward for those already using custom boxes. The materials remain the same; only the closure method changes. This makes it easier to test on smaller runs before committing to full adoption.

Functionally, they improve the handling process while keeping costs predictable and implementing it simply.

Customization isn’t Compromise

Many packaging solutions add steps, but tear strips remove them. They cut down opening time, reduce damage during unboxing, and keep the process consistent across shipping centers, retail locations, and returns.

This kind of efficiency matters most when scaling. Tear strips help standardize how custom mailer boxes are opened and inspected, making it easier to manage volume without sacrificing security or speed.

For returns, resealing becomes simpler too. Some versions allow for built-in second adhesive strips. That means fewer materials, fewer handling errors, and faster turnaround.

They also support a clean presentation from the start. There are no ripped edges or messy openings that distract from the product or branding inside the custom boxes.

Over time, small time savings and damage prevention turn into stronger performance across the entire packaging cycle. Tear strips give packaging teams more control, not more steps.

Conclusion

Security and convenience don’t have to compete. Adhesive tear strips bring both to the table—securing the shipment while simplifying access. They reduce friction, speed up handling, and preserve the product’s and packaging’s integrity.

As packaging demands grow, relying on solutions that hold up under pressure without adding complexity makes sense. Tear strip mailer boxes do that well. They integrate smoothly into existing systems and add long-term value without inflating costs.

The trade-off between tamper resistance and user-friendliness is no longer necessary. Custom mailer boxes can be protective and efficient with innovative design and the right materials.

Security matters. So does experience. And with this approach, you’re not forced to pick one over the other.