Introduction

Industrial products require more than just functionality—they demand consistency, precision, and durability. Whether producing components for automotive, medical, or heavy machinery sectors, choosing experienced plastic injection molders is essential for success.

At RapidMolding.com, skilled molders bring decades of experience to every project, delivering custom plastic parts tailored for industrial use. Their advanced techniques, rapid delivery, and focus on quality make them a trusted partner for manufacturers worldwide.

Who Are Plastic Injection Molders?

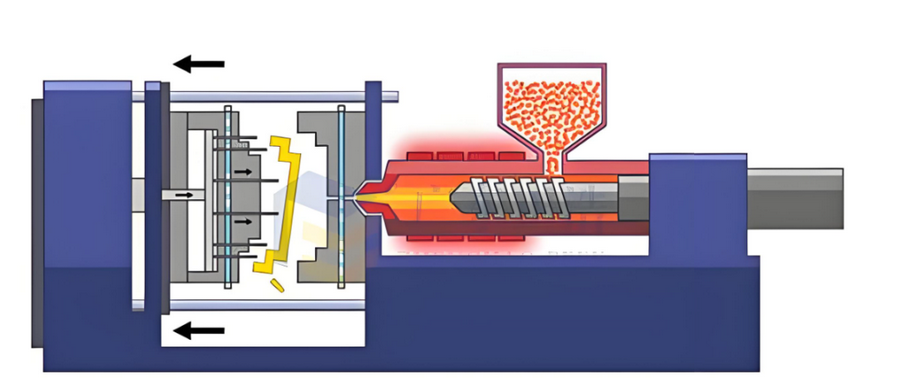

Plastic injection molders are specialists in producing molded plastic parts by injecting molten plastic into precision-engineered molds. These experts handle everything from tool design and material selection to production and quality control.

In industrial applications, where even minor defects can lead to system failure, having a skilled molder ensures each part meets strict technical standards.

Why Industrial Applications Need Expert Injection Molders

Industrial sectors face unique challenges, including extreme environments, heavy use, and tight tolerances. Skilled plastic injection molders understand these demands and provide reliable solutions.

Key Benefits:

- ✅ Consistency at Scale – Thousands of identical parts with no deviation

- ✅ Tight Tolerances – Critical for mechanical fits and safety

- ✅ Material Versatility – Selection of plastics that withstand heat, pressure, and wear

- ✅ Fast Turnaround – Meet project timelines without delays

- ✅ Compliance – Adherence to industry-specific standards (ISO, RoHS, etc.)

Capabilities of RapidMolding.com

RapidMolding.com’s team of experienced plastic injection molders provides end-to-end support, from design consultation to high-volume production. Every project is customized to match specific industrial needs.

Services Offered:

- 🛠 Tooling Design and Fabrication – High-durability molds

- 🧪 Material Consulting – Select plastics for strength, durability, and compliance

- 🔧 Precision Molding – Multi-cavity and complex geometries

- 🔍 Quality Assurance – Rigorous testing and inspection

Industrial-Grade Materials

Choosing the right plastic is crucial for long-term part performance in industrial environments.

Common Materials:

- Nylon – Tough, wear-resistant

- Polycarbonate – Impact-resistant and strong

- ABS – Versatile and cost-effective

- PEEK – High temperature and chemical resistance

- Glass-Filled Plastics – Enhanced stiffness and durability

Applications in Key Industries

Skilled plastic injection molders support a wide range of industries by delivering components that meet exacting requirements.

Automotive:

- Dashboard components, fasteners, connectors

Medical:

- Casings for instruments, surgical tool components

Industrial Machinery:

- Gears, spacers, housings, valve parts

Electronics:

- Enclosures, brackets, switches

Consumer Products:

- Handles, levers, packaging components

Customization and Value-Added Services

RapidMolding.com ensures every part is optimized for performance and usability.

Features Include:

- Threaded inserts, overmolding, and part assembly

- Surface finishes: textured, polished, matte

- Color matching and part branding

- Mold maintenance and storage

Production Volume Flexibility

No matter your order size, RapidMolding.com offers flexible solutions.

- 🧩 Prototypes – Fast, low-cost tools for testing

- 🏗 Bridge Tooling – Mid-volume with moderate tooling cost

- 🏭 Full Production – High-volume, automated part runs

Why Choose RapidMolding.com?

- ✔ Skilled Workforce – Experienced molders and engineers

- ✔ Advanced Equipment – CNC, EDM, automated molding systems

- ✔ Reliable Timelines – Fast lead times, on-time delivery

- ✔ Competitive Pricing – Cost-effective without quality compromise

- ✔ Long-Term Support – From initial quote to repeat production

Conclusion

When your business depends on precise, reliable components, you need skilled plastic injection molders who understand industrial demands. RapidMolding.com combines technical expertise with modern manufacturing to deliver custom parts that perform under pressure.

Contact RapidMolding.com Today

Get a quote and discover how expert plastic injection molders can help power your next industrial project—on time and on spec.