In a dynamic field of robotics, the incorporation of a simulation technology has proven to be a transformative development. Specifically, the robot arm simulator has completely changed how we think about robot deployment, programming, and design. These innovative instruments are a priceless resource for companies, alongside researchers, as well as educators alike because they provide a plethora of benefits, including increased safety and cost savings.

1.Cost-Effective Exploration and Experimentation

Robot arm simulators offer several advantages, chief among them the reduction of financial risks entailed in physical prototyping as well as testing. Through the creation of virtual environments that faithfully mimic real-world situations, these simulators allow users to experiment alongside exploring different robot configurations, operational strategies, and programming algorithms without having to pay for expensive physical hardware and resources. Before moving forward with actual implementation, engineers can use simulation to find possible problems, and improve designs, in addition to maximizing performance.

2.Accelerated Development and Training

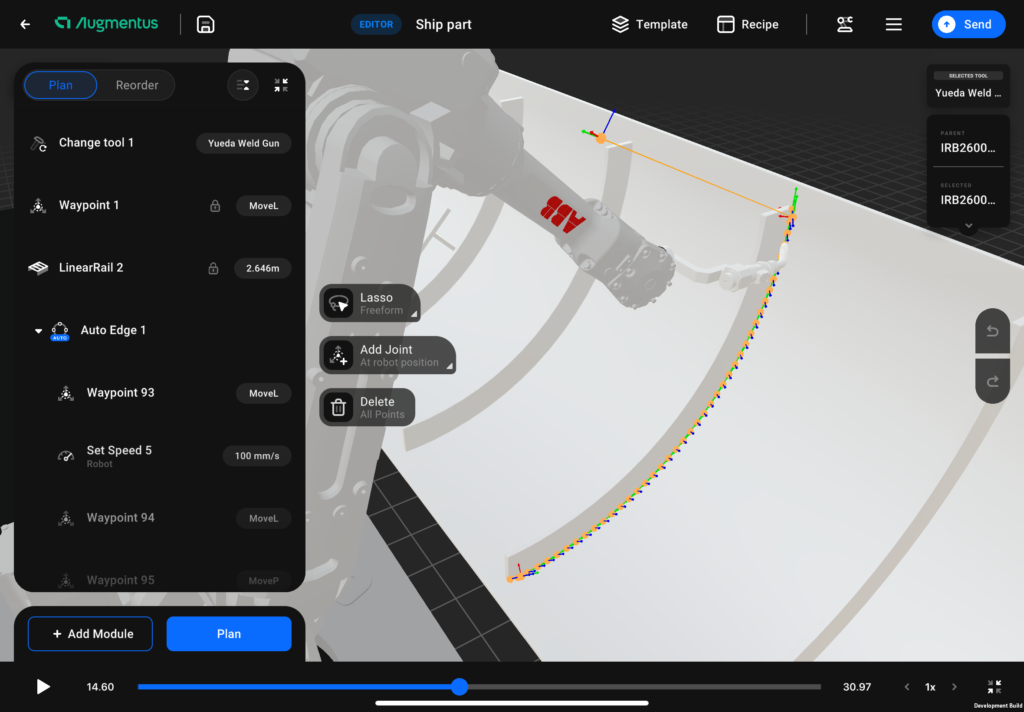

In the rapidly evolving field of robotics, efficiency is paramount. Robot arm simulators offer an effective platform for quickening the training and development phases. Researchers, developers, as well as operators can quickly test and improve algorithms, motion planning techniques, and control systems without requiring physical hardware setups by building virtual replicas of robots in addition to their environments. This simplified method does away with the laborious process of setting up as well as resetting physical robots, enabling quick experimentation and assessment of various situations.

3.Enhanced Safety and Risk Mitigation

In robotics, safety is of the utmost importance, especially when using big, strong robot arms. Simulators reduce the possibility of mishaps, injuries, or damage to pricey equipment by providing a safe and controlled environment for testing and troubleshooting. Through precise simulation of the kinematics, alongside dynamics, as well as physical limitations of robot arms, simulators allow users to foresee as well as mitigate possible risks prior to deploying robots in real-world environments.

4.Collaborative and Remote Access

Robot arm simulators enable smooth remote access in addition to collaboration, overcoming geographic limitations alongside promoting effective cross-border teamwork. Multiple users can access and interact with the same virtual environment simultaneously with cloud-based or networked simulation platforms, exchanging ideas, coordinating efforts, and utilizing collective expertise. This cooperative method encourages information exchange, in addition to speeds up problem-solving, as well as improves team member communication, all of which contribute to more effective and successful projects in the end.

5.Versatility and Scalability

Robot arm simulators provide users with unmatched scalability and versatility, enabling them to investigate a multitude of scenarios as well as applications. These simulators are designed to serve a wide range of industrial, alongside medical, as well as research applications by modelling different robot arm configurations, from basic articulated arms to intricate multi-jointed systems. Simulators also make it simple to add features like obstacles, conveyor belts, and more to environments, allowing users to test and optimize intricate systems along with procedures.

Conclusion

The robotics control software has become an essential tool for promoting innovation, and efficiency, along with safety as the need for robotic solutions in a variety of industries grows. Businesses, researchers, and educators can open up new avenues, expedite procedures, as well as stay ahead of the curve in the quickly developing field of robotics by utilizing simulation.