Accuracy and consistency are the foundation of success in today’s industry. No issue, whatever your niche, whether it is manufacturing, pharmaceutical, food processing, energy production, you need precise temperature measurement to make sure safety, effectiveness, and product quality or integrity. And that is where the Resistance Temperature Detector (RTD) becomes very essential. Well-known for their high accuracy, temperature measurement stability, and long-term reliability, they have become a trustworthy option for various industries to enhance process integrity and ensure lasting reliability.

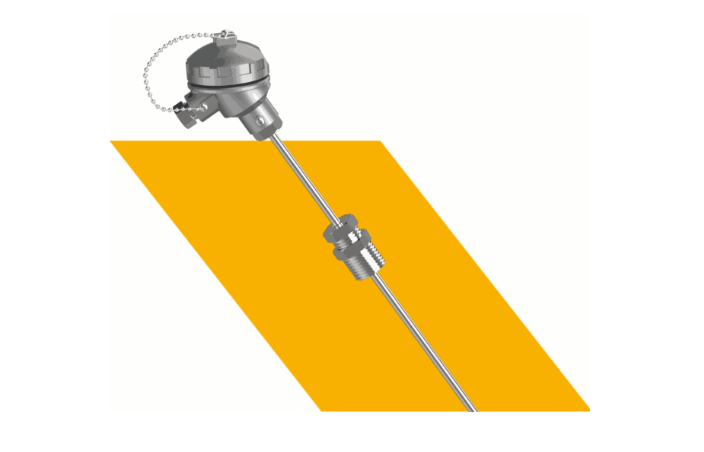

What Is An RTD?

A Resistance Temperature Detector is employed to measure temperature by linking the resistance of a material, usually platinum, to temperature. Because of increasing temperature, the electrical resistance of the element increases in a most identifiable and repeatable manner, and allows very accurate temperature measurement.

They are more authentic than other sensors, for example, thermocouples, specifically in applications where control of temperature is an issue. This is why they are the sensor of choice in places where process temperatures can not be authorised to vary.

Top Reasons Reliability Matters in Industrial Process

In various branches, a slight difference in temperature can also be life-threatening. For instance:

- In the pharmaceutical sector, inappropriate heating can have a compromised effect on the product’s efficiency.

- With food handling, uneven temperatures can lead to loss of safety and shelf life.

- In chemical plants, if there is too much heating or cooling, reactions suffer, leading to losses and expensive waste.

Having a reliable temperature measurement, RTDs can help your business minimise waste and aid in maintaining process control and product quality, and maintain overall safety.

Benefits Of Resistance Temperature Detectors

These instruments are known for their precise and reliable measurement even in a rough environment. The primary advantages of it are:

1. High Precision

RTDs are extremely accurate and have tolerances that are very low. This accuracy becomes even more critical for applications like the manufacture of medical devices.

2. Strength and Repeatability

Most sensors will degrade in performance over time, regardless of how well users maintain them, except RTDs, which will never lose stability. They will always have the same resistance-temperature characteristics to provide a repeatable operation. They are ideal for applications where long-term stability is of concern.

3. Wide Temperature Variety

Platinum-based RTDs can be used in practice over an extreme temperature range, ranging from sub-freezing to high temperatures. They are used across a broad array of applications for this very reason.

4. Sturdiness

RTDs are designed to operate continuously regardless of environment– whether that be conditions of pressure, vibration, or other chemical exposure.

5. Automation Compatibility

As industries are going to be digitalised and automated, RTDs interface with advanced tracking and control systems, allowing real-time process control.

What are the Important Uses of RTDs in Industries?

There are a number of applications of RTDs, but some of the most prominent are:

1. Chemical or Petrochemical plants

Particular attention must be given to baking in the fire and temperature control in order to be safe in the reaction and not to get into an accident.

2. Pharmaceuticals

Preserving medications in the right conditions to ensure quality and adherence.

3. Food and Beverage Production

These industries can scrutinise the cooking, cooling, and storage temperatures of their food to make sure good quality and serve safe food.

4. Generators

Boilers, turbines, and other equipment that regulate temperature for efficiency and safety.

5. HVAC and Environmental Systems

Maintaining proper temperature levels of boilers, turbines, and other systems for protective and effective use.

In these application areas, RTDs offer increased process reliability by providing more reliable temperature information due to the high importance of temperature as a parameter.

How Is A Resistance Temperature Detector Different from Other Sensors?

While thermocouples and other temperature sensors are common, RTDs specifically prove to be beneficial in applications that require accuracy, stability, and repeatability. Thermocouples can indeed offer benefits at very high temperatures or in harsh operating conditions, but history depicts that they often fail to provide enough long-term accuracy and drift performance. Conversely, RTDs are popular as they are trustworthy even in small changes, which can sometimes create issues in some applications.

What Is The Future Of RTDs In Industries?

With all markets shifting towards automation, green life, and energy savings, the requirement for reliable sensors is increasing. The latest RTDs offer attributes like digital signal output, high environmental pressure resistance, and better incorporation into IoT-based monitoring networks. In addition to increasing the redundancy of the processes, these are advancements that get the projects a step closer to meeting their goals in sustainability and efficiency.

Conclusion

In some modern industries, where accuracy and dependability can be decisive between failure and success, the Resistance Temperature Detector is a tool that is indispensable. For the best in temperature sensor technology when a cutting-edge industry demands nothing less than the optimal, Tempsens has positioned itself as a leading contender in the segment. They are highly experienced, outfitted with state-of-the-art technology, and dedicated to innovation to provide reliable solutions for different industry requirements. Thus, getting associated with experts like Tempsens, businesses can certainly increase the trustworthiness of the process and be sure of success for years.