Introduction to Wood Engraving Machines

Wood engraving machines are specialized tools designed to create intricate designs, patterns, and engravings on various wood surfaces. These machines employ advanced technology to precisely carve intricate details into wooden materials, transforming them into beautiful and functional pieces of art or practical items.

The importance of wood engraving machines lies in their ability to enhance the aesthetic appeal and value of wood products, from decorative items to functional furniture. They allow for a wide range of applications, including personalization, branding, and artistic expression, making them invaluable tools in the woodworking industry and beyond.

At the heart of wood engraving machines is the integration of computer-controlled systems and specialized cutting tools or laser beams. This technology enables precise and intricate engraving, ensuring consistent quality and accuracy in the finished product.

In the modern industry, wood engraving machines have become essential tools for woodworkers, artisans, and manufacturers alike, enabling them to create unique and visually stunning pieces while meeting the demands of a competitive market.

Types of Wood Engraving Machines

Wood engraving machines come in various types, each offering unique features and capabilities to suit different needs and applications. Here is an overview of the most common types:

CNC (Computer Numerical Control) wood engraving machines: These machines use computer-controlled cutting tools to engrave designs on wood surfaces. They offer high precision, versatility, and the ability to handle complex designs.

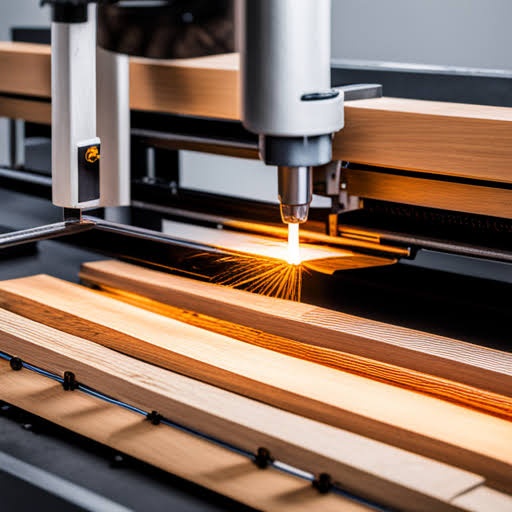

Laser wood engraving machines: Utilizing focused laser beams, these machines can create highly detailed and intricate engravings on wood surfaces. They are known for their speed, accuracy, and ability to handle delicate patterns.Laser wood engraving machines: Utilizing focused laser beams, these machines can create highly detailed and intricate engravings on wood surfaces. They are known for their speed, accuracy, and ability to handle delicate patterns. CO2 laser engraving machines are a popular type of laser engraving machine used for wood engraving.

CO2 laser engraving machines: These machines use a carbon dioxide (CO2) laser beam to precisely engrave or cut through the wood surface. The focused laser beam vaporizes or burns away the material, creating the desired design or pattern. CO2 lasers are particularly effective for wood engraving due to their ability to produce fine details and their compatibility with a wide range of wood types.

Handheld and manual wood engraving machines: These machines are designed for smaller-scale projects and hobbyists. They offer a more hands-on approach to engraving and allow for greater control over the engraving process.

Each type of wood engraving machine has its own advantages and disadvantages. CNC machines offer high precision and versatility but can be more expensive and require specialized software and programming skills. Laser engraving machines are fast and accurate but may have limitations in terms of material compatibility and depth of engraving. Handheld and manual machines are more affordable but may be less precise and require more skill from the operator.

How Wood Engraving Machines Work

Wood engraving machines employ different working principles depending on their type, but they all share the common goal of precisely removing material from the wood surface to create intricate designs and patterns.

In CNC wood engraving machines, the process involves digitizing the desired design and converting it into a toolpath that the machine can follow. The cutting tool, typically a rotating bit or router, is then moved along the programmed toolpath, precisely removing material from the wood surface to create the engraving.

Laser wood engraving machines, on the other hand, utilize a focused beam of high-energy light to etch or engrave the wood surface. The laser beam is precisely controlled by a computer system, allowing for highly detailed and intricate engravings. The laser beam vaporizes or burns away the material from the wood surface, creating the desired design.

Manual wood engraving machines rely on the skill and expertise of the operator. These machines typically feature a rotating cutting tool or a chisel-like engraving tool that the operator guides along the wood surface to create the desired engraving. The engraving process requires a steady hand, attention to detail, and a deep understanding of the tools and techniques involved.

Applications of Wood Engraving Machines

Wood engraving machines have found widespread applications across various industries and sectors, each leveraging their unique capabilities to create functional and aesthetically pleasing products. Here are some of the most common applications:

Woodworking industry: Wood engraving machines are extensively used in the furniture-making, cabinetry, and flooring industries for creating intricate designs, personalized engravings, and decorative elements on wood products.

Art and crafts: Artisans and craftspeople employ wood engraving machines to create personalized gifts, decorative items, signage, and other artistic pieces, allowing them to express their creativity and produce unique works of art.

Industrial applications: Manufacturers and industries utilize wood engraving machines for branding, serial numbering, and prototyping purposes. These machines enable precise and consistent engraving on wood products, ensuring accurate and legible markings or designs.

For example, in the furniture industry, wood engraving machines are used to create intricate carvings and decorative patterns on furniture pieces, adding value and enhancing their aesthetic appeal. In the art and crafts sector, artisans use these machines to engrave personalized messages, designs, or artwork on wooden gifts, creating unique and meaningful pieces for their customers.

Benefits of Wood Engraving Machines

Wood engraving machines offer numerous benefits that contribute to their widespread adoption and popularity:

Precision and accuracy: These machines are capable of creating highly detailed and intricate engravings with exceptional precision and accuracy, ensuring consistent quality in the finished product.

Versatility in design and customization: Wood engraving machines allow for a vast array of designs and customization options, enabling users to create unique and personalized products that stand out in the market.

Time and cost efficiency: With the help of automated processes and advanced technology, wood engraving machines can significantly reduce production time and costs, making them a cost-effective solution for businesses and individuals alike.

Sustainability and environmental considerations: Many wood engraving machines use eco-friendly techniques, such as laser engraving, which minimize waste and reduce the environmental impact associated with traditional engraving methods.

Challenges and Limitations

While wood engraving machines offer numerous benefits, they also present some challenges and limitations that users should be aware of:

Material constraints: Not all types of wood are suitable for engraving, and certain wood species or densities may pose challenges in terms of engraving quality or depth.

Maintenance requirements: Wood engraving machines, particularly those with moving parts or cutting tools, require regular maintenance and calibration to ensure optimal performance and longevity.

Initial setup costs: While cost-effective in the long run, some wood engraving machines, such as CNC and laser systems, can have relatively high initial setup costs, which may be a barrier for small businesses or hobbyists.

Skill level required for operation: While some wood engraving machines are designed for ease of use, others may require specialized training or a certain level of expertise to operate effectively, particularly for complex designs or intricate engravings.

By understanding these challenges and limitations, users can make informed decisions and take appropriate measures to overcome them, ensuring the successful implementation and operation of wood engraving machines in their respective applications.

Choosing the Right Wood for Engraving

Selecting the right wood for engraving is crucial to achieving high-quality results and ensuring the longevity of the finished product. Several factors should be considered when choosing wood for engraving, including hardness, grain, and color.

Hardness is an essential consideration, as softer woods may be more prone to tearing or splintering during the engraving process, while harder woods can withstand intricate engraving without compromising the design’s integrity. Oak, maple, and cherry are among the recommended hardwoods for engraving due to their durability and fine grain.

The grain pattern of the wood also plays a role in the final appearance of the engraved design. Woods with a straight, uniform grain pattern tend to produce cleaner and more defined engravings, while those with irregular or pronounced grain patterns may result in a more textured or rustic look.

Color is another important factor, as the natural hue of the wood can complement or contrast with the engraved design. Light-colored woods, such as maple or birch, provide a clean canvas for detailed engravings, while darker woods like walnut or mahogany can add depth and richness to the design.

Proper preparation of the wood surface is essential for achieving optimal engraving results. This typically involves sanding the surface to a smooth finish and, in some cases, applying a sealing agent to prevent the wood from splintering or absorbing moisture during the engraving process.

Maintenance Tips for Wood Engraving Machines

Proper maintenance is crucial for ensuring the longevity and optimal performance of wood engraving machines. Here are some essential maintenance tips:

Regular cleaning and lubrication: Keeping the machine clean and free from debris buildup is essential for smooth operation. Additionally, lubricating moving parts according to the manufacturer’s instructions can prevent premature wear and tear.

Calibration and alignment checks: Regularly checking the calibration and alignment of the cutting tools or laser beams can help maintain accuracy and prevent potential issues that may affect the quality of the engraving.

Troubleshooting common issues: Being familiar with common issues, such as dull cutting tools, misalignment, or software errors, can help identify and resolve problems quickly, minimizing downtime and ensuring consistent performance.

Safety Precautions

Operating wood engraving machines requires adherence to proper safety precautions to prevent accidents and injuries. Here are some essential safety considerations:

Wearing protective gear: It is crucial to wear safety glasses, gloves, and appropriate clothing to protect against flying debris, dust, and potential injuries during operation.

Proper ventilation: Wood engraving can generate fumes and dust, which can be harmful if inhaled. Ensuring proper ventilation or using a dust collection system is essential to maintain a safe working environment.

Training and supervision: New users should receive proper training and supervision to understand the safe operation of the machines and prevent accidents due to inexperience or mishandling.

Future Trends in Wood Engraving Technology

The field of wood engraving is continuously evolving, driven by technological advancements and changing market demands. Here are some potential future trends in wood engraving technology:

Advancements in CNC and laser technology: Ongoing improvements in CNC and laser technology may lead to faster, more precise, and more efficient engraving capabilities, enabling greater detail and complexity in designs.

Integration of AI and automation: The incorporation of artificial intelligence (AI) and automation could revolutionize the design and toolpath generation processes, making them more intuitive and streamlined while reducing human error.

Sustainable practices: As environmental concerns continue to grow, there will likely be an increased focus on sustainable practices in the wood engraving industry, such as using eco-friendly materials, energy-efficient machines, and minimizing waste.

DIY Wood Engraving Projects

Wood engraving can be a rewarding and creative hobby for both beginners and experienced enthusiasts. Here are some ideas for DIY wood engraving projects:

Step-by-step guides for beginner-friendly projects: Consider providing detailed, step-by-step instructions for simple projects like personalized coasters, engraved photo frames, or custom-made signs. These projects can help novices develop their skills and gain confidence with wood engraving.

Tips for sourcing materials and designing custom artwork: Offer suggestions on where to find affordable wood materials and provide guidance on designing custom artwork or selecting existing designs for engraving projects.

Inspiration for creative and unique engraving ideas: Share innovative and unique engraving ideas to inspire readers and encourage them to explore their creativity. This could include decorative wall hangings, personalized kitchenware, or engraved furniture pieces.

Conclusion

Wood engraving machines have revolutionized the way we create intricate designs and patterns on wood surfaces. From the furniture-making industry to artisanal crafts, these powerful tools offer precision, versatility, and endless possibilities for artistic expression and functional applications.

As technology continues to evolve, wood engraving machines will become more advanced, efficient, and sustainable, enabling us to push the boundaries of what is possible in the world of wood engraving.

Whether you are a professional woodworker, a creative hobbyist, or simply someone who appreciates the beauty and craftsmanship of engraved wood pieces, exploring the world of wood engraving machines can open up a world of possibilities. Unleash your creativity, experiment with different techniques, and let these remarkable machines bring your visions to life in stunning detail.