Open a kitchen drawer, pop the hood of a scooter, or flip over a laptop charger—chances are you’re touching either a thermoplastic part or a thermoset part. One can be reheated and reshaped; the other, once cured, is set for life. Picking between them isn’t just a materials decision; it’s a business decision that touches tooling, cycle time, compliance, and even end-of-life. If you want a crisp, real-world view (with a deeper explainer on thermoplastic and thermoset plastic, this guide has you covered.

The kitchen-table explanation

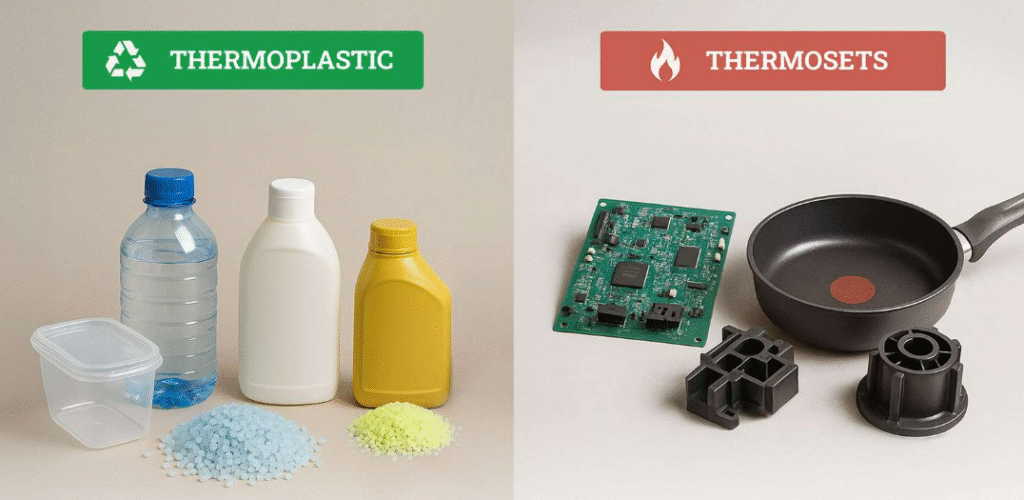

- Thermoplastics: Imagine butter. Warm it and it softens; cool it and it hardens—repeatable without wrecking the chemistry. Common names: PP, PE, PET, PVC, PC, ABS, Nylon. They’re great for high-volume parts, smooth finishes, and recycling loops.

- Thermosets: Think of an egg. Once it’s cooked, there’s no going back. Epoxy, phenolic, melamine, and some polyurethanes cure into a crosslinked network that won’t melt; push them too far, and they char. You choose them when stability at heat and under load is non-negotiable.

For a side-by-side refresher you can share with your team, keep this overview handy: thermoplastic and thermoset plastic.

How they behave when things get hot, cold, fast, or rough

Heat & dimensional stability

Thermosets shrug at bake cycles, hot housings, and long dwell at temperature. Thermoplastics range widely: PP is fine for room-temp interiors, PC/ABS pushes into under-hood zones, and high-performance grades (PEEK, PSU) go further—at a price.

Impact & ductility

If you need parts that can take a knock—helmets, interior trim, bumpers—tough thermoplastics are hard to beat. Thermosets tend to be stiffer and more brittle unless reinforced, but deliver excellent creep resistance over time.

Chemicals & flame

Polyolefins (PE/PP) resist many household chemicals; engineered thermoplastics bring solvent resistance when specified correctly. Phenolics and certain epoxy systems excel in flame/smoke performance without heavy additive packages.

Cosmetics

Colour matching, textures, and paint/print adhesion are typically easier with thermoplastics. If you live or die by showroom finish, that matters.

What production looks like on the floor

Thermoplastics love speed. Injection moulding, extrusion, blow moulding, thermoforming—fast cycles, quick changeovers, and efficient regrind use (with controlled ratios). They’re ideal for millions of parts where consistency and throughput rule.

Thermosets love structure. Compression moulding, transfer moulding, RIM, RTM—processes that pair beautifully with fibre reinforcement (glass or carbon). Cure times are longer, but the result is high stiffness-to-weight and thermal stability, perfect for electrical laminates, cookware handles, and structural panels.

Cost, risk, and the “total cost of ownership.”

- Tooling & cycle time: Thermoplastics often win on cycle speed and predictable per-part costs.

- Scrap & rework: You can reprocess some thermoplastic scrap; thermoset scrap is usually downcycled as filler.

- Warranty risk: If your failure mode is heat-induced creep or dimensional drift, thermosets can lower lifetime risk. If your pain is cosmetic rejects or fast design refreshes, thermoplastics pay back via agility.

- Energy profile: Efficient thermoplastic molding can be energy-lean; thermoset curing has a different footprint—worth modeling early.

Sustainability and circular design (the honest version)

Thermoplastics integrate more naturally into existing recycling streams—especially when you design for single-polymer parts, sensible colour choices, and easy disassembly. Thermosets, thanks to crosslinking, are harder to recycle mechanically; typical end-of-life routes include grinding for fillers or energy recovery, with promising (but still maturing) chemical/thermal options. If circularity is a KPI, that can tip borderline choices toward thermoplastics.

Want a deeper dive into trade-offs? Bookmark thermoplastic and thermoset plastic for quick reference.

A five-question filter to choose faster

- Temperature map: What’s the max continuous temperature? How long do you stay there, and where are the hot spots?

- Mechanical profile: Is your priority impact and snap-fit flexibility (thermoplastic), or stiffness and creep resistance under load (thermoset)?

- Regulatory & environment: Food contact? UL flame ratings? Electrical insulation? Chemical splash? Let compliance narrow your shortlist.

- Volume & cadence: Millions of units with frequent design tweaks favor thermoplastics; fiber-reinforced, high-heat laminates often point to thermosets.

- End-of-life plan: Can you keep it single-material? Can inserts be removed? Do local recyclers accept the grade? Decisions here save money later.

Mini case studies (because theory is never the whole story)

- Two-wheeler mirror housing (thermoplastic): ABS or PC/ABS offers toughness for everyday knocks, paints well, and moulds fast—ideal for cost-sensitive, style-driven parts.

- Cookware handle (thermoset): Phenolic stays dimensionally stable next to heat over years of use; no softening during stovetop blasts.

- EV battery spacer (depends): If the part faces long, hot dwell and needs excellent electrical insulation, a glass-filled thermoset laminate fits. If it’s a lower-heat, high-volume clip with strict tolerances, an engineered thermoplastic can work with the right grade and design.

- Reusable bottle (thermoplastic): HDPE or PET supports blow moulding, clarity/toughness trade-offs, and established recycling routes.

Mistakes that quietly drain budgets

- Over-engineering “just in case.” Specifying a high-temp resin where PP or ABS would do increases cost and complicates recycling.

- Ignoring moisture practices. Nylon and other hygroscopic thermoplastics require proper drying; skip it, and you’ll encounter warpage and weak weld lines.

- Incompatible stacks. Flame retardants, paints, adhesives, and overmolds must be tested with your base resin, not assumed.

- Composite chaos. A beautiful tri-material assembly today can become tomorrow’s landfill if not designed for disassembly.

- Regulatory afterthoughts. UL, ROHS, REACH, FDA/EFSA—late surprises are expensive; align early with your materials supplier.

Design moves that make everything easier.

- Design for disassembly: Use screws, snap-fits, and fewer permanent bonds; it helps rework, repair, and recycling.

- Specify colour with intent: Natural or lighter shades improve downstream options; deep carbon black often limits sorting.

- Pilot regrind ratios: Increase recycled content in controlled steps and validate mechanicals at each step.

- Document like a pro: Record grade, melt flow, colour code, additives, and supplier—future you (and your recycler) will thank you.

- Test in the real world: Heat-soak parts, chemical-splash them, drop-test prototypes—because lab numbers don’t capture mounting bosses and living hinges.

Quick reference: where each typically wins

Thermoplastics

Consumer housings, interior trim, bottles and closures, piping, films, snap-fit enclosures, trays, lenses, protective gear. You’re looking for speed, cosmetics, ductility, and a clearer recycling pathway.

Thermosets

Circuit board laminates (FR-4), high-heat housings, cookware handles, encapsulations, tooling, structural composites (with fibres). You’re looking for dimensional stability, heat performance, dielectric strength, and long-term creep resistance.

The bottom line

There’s no single “best” family; there’s only the right material for your constraints. If your product lives in a high-heat, high-load, low-creep world, thermosets provide confidence you can feel. If you need fast cycles, crisp cosmetics, easy iteration, and realistic routes to reuse, thermoplastics shine—especially when you design with circularity in mind.

When you’re weighing trade-offs or building a materials brief for stakeholders, keep this handy explainer close: thermoplastic and thermoset plastic. Map those principles to your temperature profile, compliance list, volume plan, and end-of-life goal. That’s how you choose a polymer that performs on Day 1—and still makes sense on the day the product retires.