Introduction

In the world of manufacturing and product development, precision and quality are key. When it comes to creating durable metal parts, choosing a reliable Metal Casting Manufacturer makes all the difference. From automotive to construction, industries rely heavily on Custom Casting Services to produce parts that meet exact specifications. In this article, we will explore how metal casting works, the benefits of custom casting, and why selecting the right manufacturer is vital for business success.

What is Metal Casting?

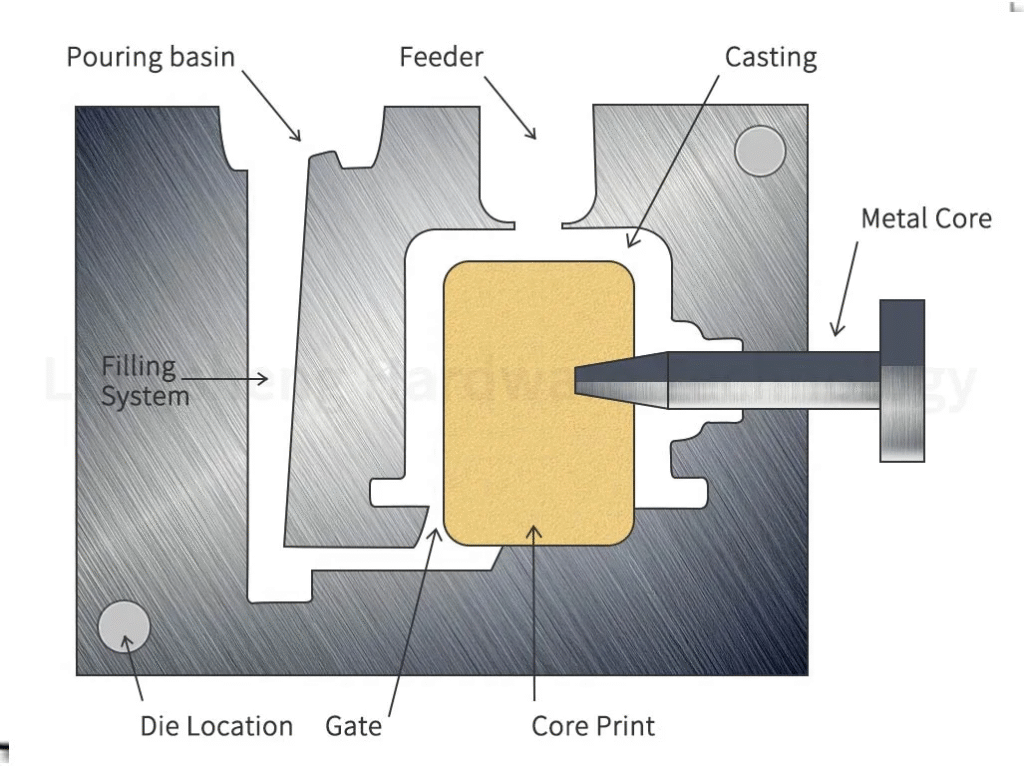

Metal casting is one of the oldest and most trusted methods of shaping metals. The process involves pouring molten metal into a mold, letting it cool, and then removing the solidified part. A professional Metal Casting Manufacturer uses advanced equipment and techniques to ensure that each cast product is strong, accurate, and ready for use.

Types of Metal Casting Processes

Different industries require different casting methods. Some of the most common techniques used by Metal Casting Manufacturers include:

Sand Casting – Ideal for low to medium-volume production.

Die Casting – Great for high-volume and high-precision parts.

Investment Casting – Perfect for complex and detailed shapes.

Centrifugal Casting – Used in producing strong cylindrical parts.

By using the right Custom Casting Services, companies can achieve the exact finish, size, and strength they need for their products.

Why Choose a Professional Metal Casting Manufacturer?

Partnering with an experienced Metal Casting Manufacturer comes with several benefits:

Consistency in Quality – Skilled manufacturers deliver parts with accuracy.

Cost Savings – Bulk production reduces costs for businesses.

Customization – Through Custom Casting Services, designs can be tailored to unique requirements.

Durability – Cast metal components are strong and long-lasting.

The Role of Custom Casting Services

Every industry has unique needs, and that’s where Custom Casting Services stand out. These services allow businesses to design and produce parts that match exact specifications. For example:

Automotive companies use custom parts for engines and gear systems.

Construction firms rely on castings for heavy-duty equipment.

Aerospace industries depend on precision casting for safety and performance.

By working with a reliable manufacturer, businesses gain access to a wide range of customized solutions.

Industries That Benefit from Metal Casting

A Metal Casting Manufacturer plays a vital role in many industries, including:

Automotive – Engine blocks, gears, and transmission parts.

Aerospace – Turbine blades and structural components.

Medical – Surgical instruments and specialized equipment.

Construction – Heavy machinery parts and tools.

Energy – Components for oil, gas, and renewable energy equipment.

Each of these sectors relies on Custom Casting Services to keep operations efficient and reliable.

How to Select the Right Metal Casting Manufacturer

Choosing the right manufacturer can determine the success of your project. Here are some factors to consider:

Experience and Expertise – Look for a company with a strong background.

Technology and Equipment – Advanced tools ensure precision and durability.

Customization Options – The ability to provide Custom Casting Services is a must.

Quality Standards – Certifications and strict inspections guarantee reliability.

Cost and Timelines – Ensure the manufacturer offers fair pricing and delivers on time.

The Future of Metal Casting

Modern Metal Casting Manufacturers are combining traditional techniques with advanced technology. 3D printing, computer-aided design (CAD), and automation are changing the way casting is done. This not only improves accuracy but also reduces waste, making the process more eco-friendly. Companies that invest in innovative Custom Casting Services will stay ahead in competitive industries.

Conclusion

Selecting the right Metal Casting Manufacturer is a crucial decision for any business that depends on strong, precise, and cost-effective metal parts. With the added benefit of Custom Casting Services, companies can design products that perfectly match their needs. Whether it’s for automotive, aerospace, or construction, metal casting continues to be a trusted process that drives industries forward. By choosing an experienced and innovative manufacturer, businesses ensure success and long-term reliability.