In an era where power electronics drive everything from renewable energy systems to electric vehicles, the vulnerability of semiconductor devices has become a critical concern for engineers and system designers. A single overcurrent event lasting mere milliseconds can destroy semiconductor components worth thousands of dollars and cause system downtime that costs exponentially more.

As semiconductor technology advances toward higher voltages, greater power densities, and faster switching speeds, the role of specialized fuse protection has evolved from optional safeguard to essential system component.

Understanding the Semiconductor Fuse Landscape

The semiconductor fuse market offers diverse technologies, each optimized for specific applications and operating conditions. HIITIO’s comprehensive range of semiconductor fuses encompasses the full spectrum of protection solutions available to power electronics designers:

Global Standard Fuses:

· British Standard BS88 Fuses – Widely adopted in European and Commonwealth markets, offering robust protection for industrial applications with standardized dimensions and performance characteristics

· North American Fiberglass Fuses – Designed to meet UL and CSA requirements, featuring fiberglass construction for enhanced mechanical strength and arc suppression

Specialized Technologies:

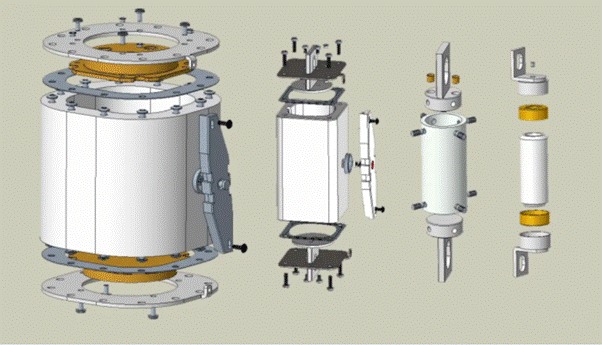

· Cartridge Ceramic Fuses – Traditional yet reliable, using ceramic bodies for excellent thermal management and arc containment in medium-duty applications

· Square Body Series Fuses – Compact designs ideal for space-constrained installations while maintaining high interrupting capacity

· Class RK5 Fuses – Current-limiting fuses that provide time-delay characteristics for motor and transformer protection

Advanced Protection:

· Pyro Fuses – Ultra-fast pyrotechnic technology delivering microsecond response times for the most sensitive semiconductor devices

Supporting Components:

· Fuse Holders – Engineered mounting solutions ensuring proper electrical contact, thermal management, and safe replacement procedures

This diversity reflects the varying demands of modern power electronics, where one-size-fits-all approaches simply cannot deliver optimal protection.

What Makes Semiconductor Fuses Different?

Standard electrical fuses are designed to protect wiring and prevent fires by interrupting circuits when current exceeds safe levels for conductors. Semiconductor Fuses operate on an entirely different principle, prioritizing the protection of expensive, fragile semiconductor junctions rather than simple copper wires. The key differences include:

Response Speed:

· Standard fuses: React in milliseconds to seconds

· Semiconductor fuses: Respond in microseconds to milliseconds, clearing faults before semiconductor devices reach their thermal limits

I²t Rating (Let-Through Energy): Semiconductor fuses are characterized by their extremely low I²t values, meaning they allow minimal energy to pass through during a fault event. This prevents the thermal damage that would occur if even small amounts of fault energy reached sensitive semiconductor junctions.

Voltage Rating and Arc Suppression: When interrupting high-voltage DC circuits, semiconductor fuses must safely extinguish the resulting arc. Advanced fuse designs incorporate specialized arc-quenching materials and geometries that rapidly deionize the plasma arc, preventing re-ignition and ensuring complete circuit isolation.

Selective Coordination: In complex power systems with multiple protection levels, semiconductor fuses are engineered to coordinate selectively, ensuring that only the fuse closest to the fault operates while upstream protection remains intact.

The Science Behind the Protection

For engineers new to semiconductor protection, understanding how semiconductor fuses work is essential for proper selection and application. The fundamental operation involves several sophisticated mechanisms:

Fuse Element Design: Semiconductor fuses utilize carefully engineered fuse elements—typically made from silver or silver alloy—with precisely controlled cross-sectional areas and geometries. During normal operation, current flows through these elements with minimal resistance. When a fault occurs, the sudden increase in current causes rapid resistive heating. The element reaches its melting point within microseconds, creating a high-resistance gap that forces current to zero.

Arc Management: The moment the fuse element melts, an electric arc forms across the gap. This arc, essentially a plasma channel, can conduct thousands of amperes if not properly managed. Semiconductor fuses contain specialized arc-quenching media—typically silica sand or ceramic powder—that absorbs the arc’s energy, cools the plasma, and increases the resistance of the arc path until current cannot be sustained.

Pressure Relief: As the fuse element vaporizes and the arc-quenching material heats up, significant pressure can build inside the fuse body. Quality semiconductor fuses incorporate pressure relief mechanisms that safely vent gases without creating external arcs or projectiles, ensuring the protection event doesn’t create new hazards.

Real-World Applications Driving Semiconductor Fuse Innovation

The expanding role of power electronics across industries continues to drive semiconductor fuse technology forward:

Renewable Energy: Solar inverters and wind turbine converters rely on semiconductor fuses to protect expensive IGBT and MOSFET modules that convert DC to AC power. A single unprotected fault can destroy power modules worth $20,000-50,000.

Electric Mobility: EV charging infrastructure and vehicle powertrains use semiconductor fuses rated for 600V-1000V DC, protecting against battery short circuits and converter failures. The automotive industry’s reliability requirements have pushed fuse manufacturers to develop products with 15+ year lifespans.

Industrial Automation: Variable frequency drives controlling industrial motors depend on semiconductor protection to prevent costly production disruptions. In 24/7 manufacturing environments, the cost of unplanned downtime often exceeds $100,000 per hour.

The Future of Semiconductor Protection

As we move toward a more electrified world—with electric vehicles, renewable energy, and advanced manufacturing driving unprecedented demand for power electronics—the sophistication of semiconductor fuses will continue to evolve. Emerging trends include smart fuses with integrated diagnostics, adaptive protection that adjusts to real-time operating conditions, and miniaturization that enables higher power densities without sacrificing protection performance.