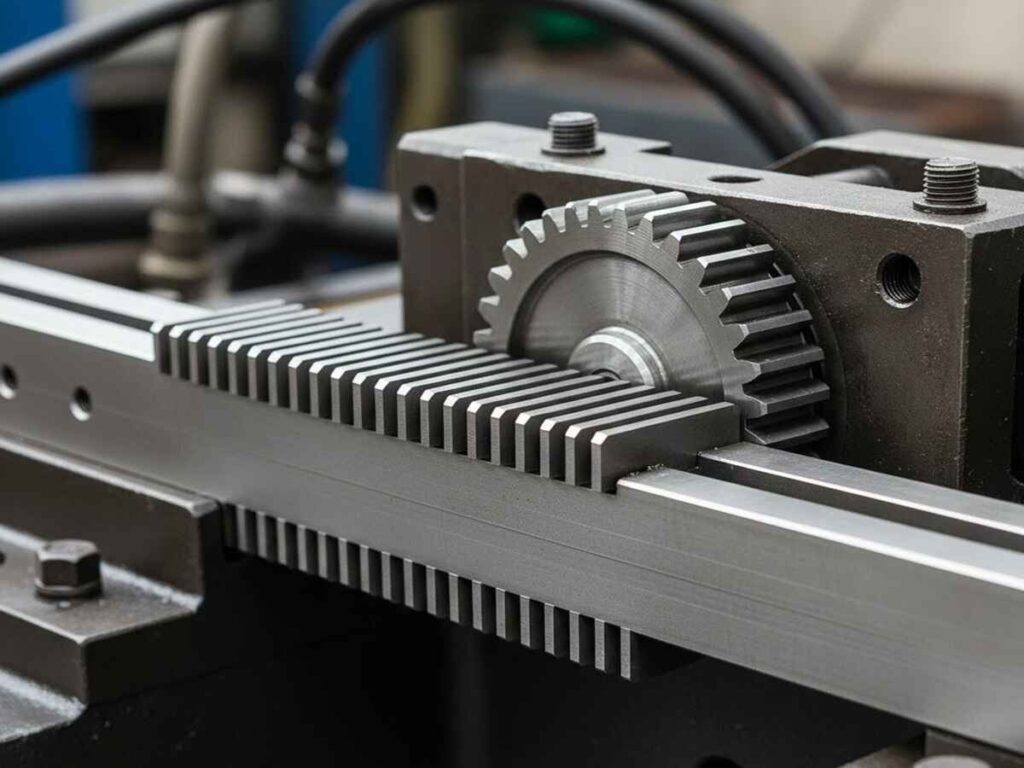

Rack gear plays a crucial role in many industrial applications, including automation systems and heavy machinery. Industries in Malaysia increasingly rely on locally made Rack Gear Malaysia for its tailored designs and consistent quality. Local production ensures products meet national standards and industrial specifications without compromise. This growing preference reflects efficiency and reliability that domestic suppliers provide.

By choosing locally made rack gear, businesses also gain better control over procurement timelines. Immediate access to technical support and troubleshooting becomes easier. Industries can respond faster to urgent operational demands and avoid delays caused by international shipping. Overall, local sourcing strengthens both efficiency and production continuity.

Cost Efficiency

Locally manufactured rack gear provides a significant cost advantage over imported alternatives. Shipping fees, import taxes, and customs duties are eliminated, reducing overall project expenses. Industries can allocate these savings to other operational areas, increasing profitability and project efficiency. The combination of affordability and quality makes local sourcing appealing.

Domestic suppliers often offer competitive pricing structures tailored to industrial clients. By negotiating directly, businesses can secure bulk orders at reduced rates. Cost efficiency, coupled with reliable quality standards, ensures industries gain maximum value. Local sourcing proves economically practical for both small and large-scale operations.

Shorter Lead Times

Domestic production allows industries to receive Rack Gear Malaysia much faster than importing from abroad. Shortened delivery schedules prevent unnecessary delays in critical projects. Industries benefit from timely procurement, which is essential for maintaining smooth production cycles. Quick access also enables businesses to adapt rapidly to market changes.

Shorter lead times contribute to improved operational planning and scheduling. Production managers can rely on consistent availability, avoiding downtime caused by late shipments. Industries achieve greater flexibility, ensuring that urgent requirements are met efficiently. Fast delivery reinforces the overall reliability of local suppliers.

After-Sales Services

Local manufacturers provide prompt after-sales support tailored to client needs. Technicians can visit industrial sites for repairs, adjustments, or consultations. Immediate assistance minimizes downtime and prevents production interruptions. Industries gain confidence knowing support is readily available.

The proximity of suppliers ensures effective troubleshooting and faster resolution of technical issues. Continuous guidance and maintenance support enhance machinery performance and reliability. After-sales services create long-term relationships between suppliers and industrial clients. These services are often more accessible than international alternatives.

Supply Chain Reliability

Sourcing rack gear locally strengthens the supply chain and reduces dependence on overseas logistics. Domestic availability ensures products are delivered consistently without transportation delays. Industries can maintain uninterrupted operations and adhere to strict production schedules. Reliability becomes a key factor in operational planning.

Stable supply chains also reduce the risks associated with global shipping disruptions. Local suppliers can adjust quickly to demand fluctuations, ensuring continuous product availability. Industries gain greater control over procurement, inventory, and project timelines. Reliable supply chains foster trust between manufacturers and industrial clients.

Reduced Risk of Damage

Shipping rack gear from overseas increases the likelihood of damage during handling and transportation. Local sourcing of Rack Gear Malaysia reduces these risks because products travel shorter distances and are handled carefully. Industries can expect equipment to arrive intact and ready for installation. Minimizing damage prevents additional costs and operational delays.

Domestic manufacturers implement strict quality control measures to ensure product safety. Inspection and packaging standards protect gear during transport. Reduced risk of damage directly contributes to smoother production processes. Industries benefit from improved operational efficiency and reduced financial exposure.

Flexible Payment Options

Local suppliers often provide flexible payment arrangements to accommodate client needs. Options such as installment plans or trade credit help industries manage cash flow effectively. Financial flexibility enables smaller companies to procure essential equipment without strain. It also strengthens long-term business partnerships.

Negotiating directly with domestic manufacturers allows for customized payment solutions. Businesses can secure bulk orders with manageable financial terms. Flexible payment options enhance trust between suppliers and industries. This makes domestic sourcing more practical and convenient than relying on imported alternatives.

Material Availability

Locally produced rack gear benefits from ready access to raw materials within Malaysia. Suppliers can source components faster and reduce production delays. Immediate availability of materials ensures that industries receive products on time and according to specifications. This advantage is critical for maintaining project schedules.

Easy access to materials also supports customization of rack gear to meet specific operational needs. Local suppliers can adapt quickly to changing industrial requirements. Industries can receive tailored solutions without the delays associated with international sourcing. Material availability enhances both efficiency and reliability.

Expertise and Experience

Malaysian manufacturers have years of expertise in producing high-quality Rack Gear Malaysia. Skilled engineers ensure products meet strict industrial standards. Their experience guarantees precision, durability, and reliability in industrial applications. This technical knowledge gives local suppliers an edge over international competitors.

Domestic engineers and technicians also contribute to innovative designs, applying their skills to complex machinery such as Helical Gear Pinion systems. Continuous training and development ensure they stay updated with technological advancements. Industries benefit from expert craftsmanship that enhances machine performance and longevity. Local experience supports both quality and operational success.

Maintenance Convenience

Locally made rack gear is easier to maintain due to proximity and accessibility of service providers. Replacement parts are readily available, and technical assistance is nearby. This convenience reduces downtime and supports smooth industrial operations. Quick maintenance ensures that machinery remains functional and efficient.

Industries can schedule repairs or inspections without waiting for overseas shipments. Convenient maintenance practices also reduce costs associated with delays and part replacements. Domestic sourcing enables faster problem resolution. Maintenance becomes more predictable and reliable for industrial clients.

Warranty Assurance

Local manufacturers typically provide strong warranty programs for their rack gear. Warranties guarantee product performance and offer reassurance to industries. Any issues are addressed promptly, reducing unexpected financial burdens. Reliable warranties ensure confidence in ongoing operations and supplier reliability.

Industries can rely on consistent performance and timely support. Strong warranties make locally made Rack Gear Malaysia a practical and secure investment. Assurance of quality strengthens long-term supplier relationships and enhances operational peace of mind.

Economic Benefits

Purchasing locally produced rack gear supports Malaysia’s economy by creating jobs and promoting industrial growth. Domestic sourcing encourages technological innovation and strengthens local manufacturing capabilities. Industries contribute to the country’s economic development while meeting operational needs.

Supporting local suppliers fosters a stable industrial environment and encourages further investment. Businesses benefit from a competitive market and improved service standards. Economic benefits complement operational efficiency, making domestic sourcing a strategic choice for industries.

Why choose MT Gear?

MT Gear & Engineering Services Sdn Bhd is a trusted provider of high-quality industrial components, specializing in rack gear solutions and supplying every type of gear to meet diverse industrial needs. Their expertise ensures clients receive durable and precise products that comply with rigorous engineering standards. With years of experience, MT Gear has established a strong reputation for reliability, innovation, and technical excellence in Malaysia.

Clients benefit from the company’s full range of services, including technical support, installation guidance, and customized solutions for all gear types. Their team of skilled engineers and technicians provides on-site assistance whenever required. Choosing MT Gear guarantees efficient operations, reduced downtime, and a long-term industrial partner capable of handling any gearing requirement.

Conclusion

Industries in Malaysia prefer locally made Rack Gear Malaysia for cost efficiency, faster delivery, and reliable after-sales support. Domestic sourcing reduces risks, ensures consistent quality, and enhances operational flexibility. Industries gain a dependable partner in local manufacturers.

With convenient maintenance, warranty assurance, and positive economic impact, locally made Rack Gear Malaysia represents a practical solution. Supporting domestic suppliers aligns industrial efficiency with national growth. Malaysian industries achieve both operational success and long-term reliability.