Welding has evolved very far beyond sparks and flames and lasers and beam accuracy. Among the existing multitude of options, TIG welding and laser welding can be considered one of the most popular options. They each possess their merits, and the real question is, which one best fits your needs? We may now have a better glimpse of how they work and of what is different about them.

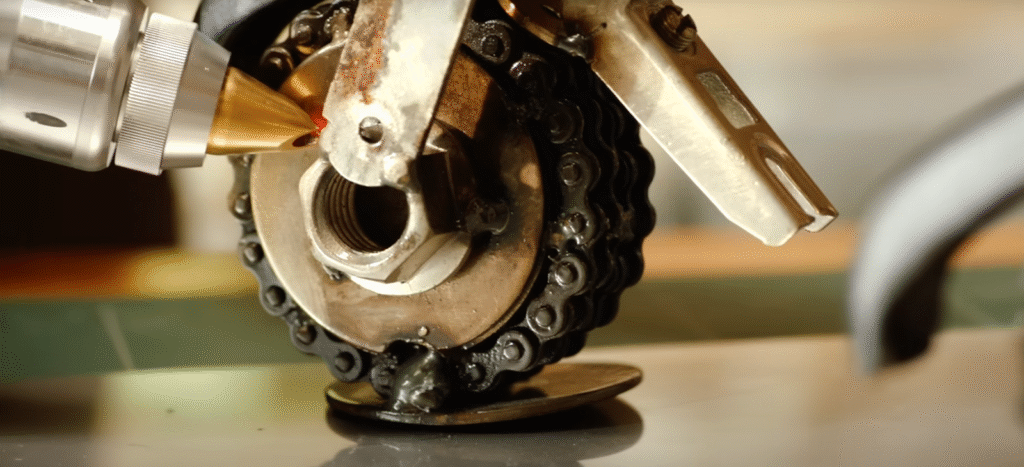

What Is TIG Welding?

TIG welding is one of the oldest and precise methods in the industry. It employs a tungsten electrode to establish an arc that heats the metal, while a shielding gas protects the weld from contamination. It’s a slow process, but an incredible (and clean) way to get detail.

Professionals Still Love TIG Welding

Many enjoy TIG welding because of the amount of control that it gives. Welders can control heat, filler metal, and movement to create smooth, high-quality joints. That means it’s ideal for more gentle materials — such as aluminum and stainless steel. Aerospace and art metal TIG welders, Metalworking with a fineness.. Many jobs demand specialized skills to achieve looks, strength, and aesthetic appeal in the finished work.

The Drawbacks of TIG Welding

Although TIG welding is visually appealing when performed correctly, it requires a great deal of skill and patience. Labor-intensive and not suited for mass projects. It also creates more heat, and in thinner metals, raises the possibility that you could warp them. If that’s not enough, then today many trades are opting for a welding laser technology, which promises faster and cleaner processing.

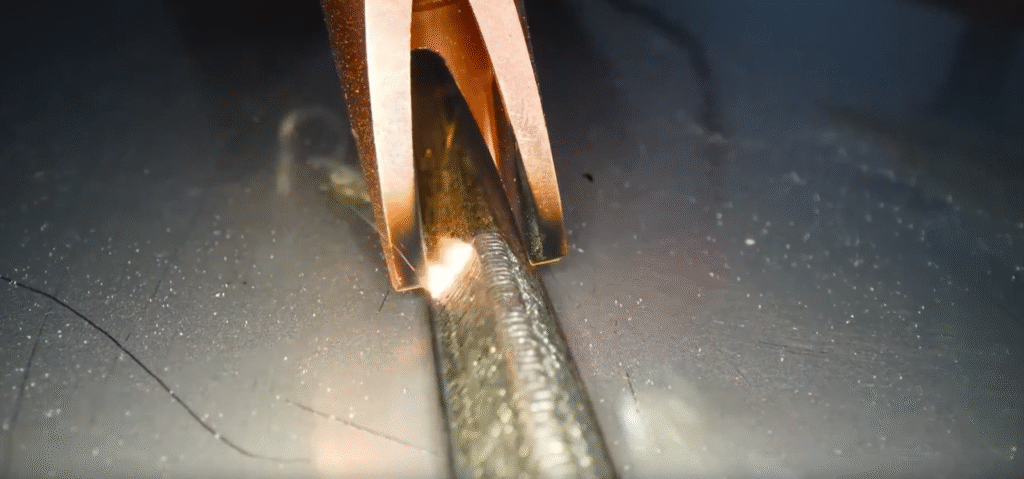

The Modern Edge: Laser Welding

As opposed to the other traditional methods of welding, laser welding involves the use of a very thin beam of light to join the metals. This high heat source effectively and precisely melts materials to create imperfect-perfect bonds. Trade craft is noncontact and, therefore, it does not wear as much, as well as there is no high possibility of contamination.

The Power of Welding Laser at Work

The laser may make deep, narrow welds with little heat effect. It is commonly used in electronics, as well as the automotive and medical manufacturing industries, where precision is highly important. It’s an automated, quick, and dependable process that’s perfect for production lines that require precision and speed.

Why Industries Prefer Laser Welding

Nothing can beat laser welding for speed and control. It reduces clean up and provides welds that need few, if any, finishing. Products such as the X1 Pro Laser Welder help facilitate clean and lasting finishes for professionals, while also saving time and energy.

XLaserlab: The Future of Welding

XLaserlab, which is a renowned brand in sophisticated welding, is at the center of this technological revolution. X1 Pro Laser Welder is a powerful, efficient and accurate system in one- that is why laser welding has become accessible to professionals and small workshops alike. You can now weld with the best of speed, neatness and smartness, using the tools of XLaserlab.

Laser Welding vs TIG Welding: Comparisons

| Feature | TIG Welding | Laser Welding |

| Speed | Slow and manual | Extremely fast and automated |

| Precision | High, but depends on skill | Ultra-precise, machine-controlled |

| Heat Distortion | Higher, especially on thin metals | Very low due to a concentrated laser beam |

| Skill Required | Requires years of experience | Easier with modern systems |

| Cost Efficiency | Lower machine cost, higher labor costs | Higher setup cost, lower maintenance |

| Applications | Artistic, aerospace, repair | Automotive, electronics, manufacturing |

Both have merit — but where their values lie may vary depending on what you want from your work.

How to Choose Which One Is Right for You

If you do really fine work, like an art piece, TIG welding is the way to go. It enables you to form, control, and finish all aspects of your weld. TIG has capabilities that are attractive to artists, repairmen, and small metal shops.

When Laser Welding Wins

Laser vs. Other Welding. For today’s industries looking for accuracy and increasing productivity, lasers beat out all others. The technology minimizes the risk of human error, accelerates the production process, and provides consistent quality output throughout a job. If you want high volume with precision, a laser welder will prove to be worth it in the long run!

The Future is Laser Welding

The world is spinning ever faster, and technology constantly alters the way we work with metals. Though TIG welds still hold their own as a craft, laser welding is pushing the envelope for what’s possible in terms of speed and perfection. A machine like the X1 Pro Laser Welder is the difference between what was and what one could only dream of with traditional methods of yore.

As with most things in hunting and life, choosing the proper technique depends on what you are trying to accomplish. If you appreciate workmanship, TIG is what to have.

Final Thoughts

Both the TIG welding and the laser welding have established their presence in the fabrication world. However, with the development of industries, the desire to gain accuracy and efficiency has led more professionals in the direction of laser technology. The Laser Welder is not only a tool, but a step towards smarter, cleaner and faster manufacturing.

As soon as you are ready to make a step further, have a look at XLaserlab – the art of precision, the science of innovation.