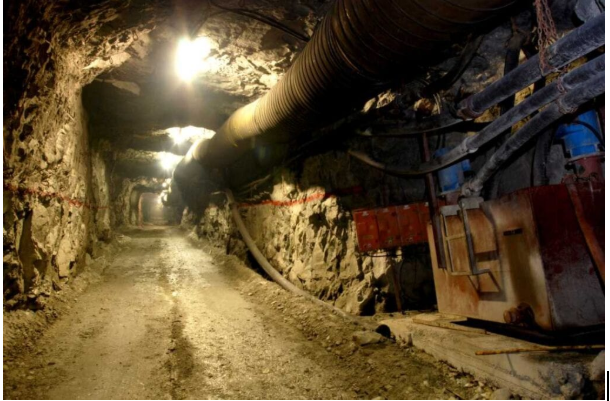

Worker safety is the most important priority in any industrial setting, and this is especially true in underground mining. Below the earth’s surface, miners face numerous hazards, from rockfalls to exposure to harmful gases. Ensuring a safe working environment is not just a regulatory requirement; it’s a moral obligation. A critical component of this safety puzzle is proper ventilation. Effective underground mining ventilation systems are essential for clearing toxic fumes, regulating temperature, and supplying fresh, breathable air to workers.

This is where specialized engineering expertise becomes invaluable. Companies that design, install, and maintain these life-sustaining systems play a pivotal role in the daily safety of thousands of miners. This post will explore how Mechvac Engineering is at the forefront of providing advanced ventilation solutions that protect workers and enhance operational efficiency in the challenging environment of underground mining.

Who is Mechvac Engineering?

For years, Mechvac Engineering has built a strong reputation for delivering high-quality, reliable engineering solutions across various industries. The company specializes in designing and implementing custom systems that solve complex industrial challenges. Their expertise is particularly pronounced in the mining sector, where they have become a trusted partner for developing robust underground mining ventilation systems. By focusing on practical, durable, and efficient designs, Mechvac ensures that their solutions meet the rigorous demands of the mining industry.

Advanced Ventilation Solutions for Underground Mines

The primary goal of any ventilation system in a mine is to create a safe and breathable atmosphere. This involves a delicate balance of pushing fresh air in and pulling contaminated air out. Mechvac Engineering has developed a range of solutions specifically tailored to the unique conditions of underground mines.

These systems are designed to manage several key environmental factors:

- Dilution of Harmful Gases: Mining activities can release gases like methane, carbon monoxide, and nitrogen oxides. Mechvac’s ventilation systems are engineered to dilute these gases to safe, non-explosive levels.

- Dust Control: The process of drilling and blasting creates significant amounts of dust, which can cause serious long-term respiratory issues. Powerful ventilation helps capture and remove airborne dust particles, clearing the air for workers.

- Temperature Regulation: Deep underground, temperatures can become extremely high due to geothermal heat and machinery operation. Effective ventilation helps to cool the working environment, reducing the risk of heat stress for miners.

Mechvac’s approach involves a thorough assessment of each mine’s specific layout and operational needs to design a bespoke system that provides optimal airflow and safety.

The Tangible Benefits of Mechvac Systems

Implementing a high-quality ventilation system from Mechvac Engineering offers more than just compliance with safety standards. The benefits have a direct impact on both the workforce and the mine’s overall productivity.

- Enhanced Worker Safety: The most crucial benefit is the significant reduction in risks associated with poor air quality. A well-ventilated mine is a safer mine, leading to fewer incidents and a healthier workforce.

- Increased Productivity: When miners can work in a comfortable and safe environment, their productivity naturally increases. Reduced downtime due to environmental hazards or equipment failure also contributes to a more efficient operation.

- Energy Efficiency: Modern underground mining ventilation systems are designed to be as energy-efficient as possible. Mechvac utilizes advanced fan technologies and system designs that minimize power consumption, leading to substantial cost savings over the life of the mine.

The Critical Role of Regular Maintenance

Installing a state-of-the-art ventilation system is only the first step. To ensure it continues to operate effectively and reliably, regular maintenance is essential. Components like fans, ducts, and filters can wear down over time or become clogged with dust and debris.

Mechvac Engineering emphasizes a proactive approach to maintenance, offering scheduled inspections and servicing to keep their systems in peak condition. This commitment helps prevent unexpected failures that could compromise worker safety and halt production. Regular maintenance ensures the system consistently delivers the required airflow and continues to protect the health of everyone underground.

Conclusion

The challenges of underground mining demand solutions that are both innovative and dependable. By focusing on robust design, quality installation, and diligent maintenance, companies like Mechvac Engineering are making a profound difference in mine safety. Their dedication to creating effective underground mining ventilation systems ensures that miners have the clean air they need to perform their jobs safely and efficiently.