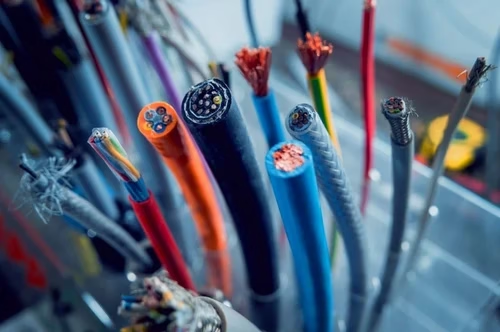

If there is at least one world in which precision really is of paramount importance, it is that of electrical installations. This is no less the case when it comes to the task of selecting the appropriate cable size for a given application.

For both professionals and DIY enthusiasts who are based in the UK, it typically feels like second nature to work with metric measurements like square millimetres (mm2), thanks to such standards as the IET Wiring Regulations (BS 7671).

What if, though, you are such an individual and you are sourcing components from American suppliers, dealing with imported equipment, or referencing legacy documentation? If this describes your situation, you might well come across the American Wire Gauge (AWG) system.

In such a circumstance, you are likely to appreciate knowing how to convert from AWG to mm2. Equipping yourself with such knowledge – and crucially, applying it – will go a long way to ensuring the safety, compliance, and efficiency of your cable sizing.

An Introduction to AWG And mm2

AWG and mm2 are both systems used for cable sizing. However, they are inversely related and have only approximate equivalents, such as 18 AWG being approximately 1 mm2, and 10 AWG being roughly equivalent to 6 mm2.

To summarise:

- AWG (American Wire Gauge) is the United States standard for denoting wire diameter. It is a logarithmic scale, where a lower AWG number equates to a thicker wire. For instance, 10 AWG is thicker, and can carry a greater amount of current, than 20 AWG.

- mm2 (square millimetres) is a direct, linear system – used internationally – for measuring the cross-sectional area (CSA) area of the conductor. This, in turn, directly influences the current-carrying capacity (ampacity) of the wire. In the UK, it is typical for cable sizes to be specified in mm2 – for example, 1.5 mm2 for standard lighting circuits.

So, to emphasise: as these two systems involve different measurement philosophies, AWG does not map perfectly to mm2. This means that conversions depend on a certain amount of approximation – although of course, the right tools can help make this a straightforward task.

At-a-Glance: Some Common AWG To mm2 Conversions

This table provides a rundown of common AWG sizes and their approximate equivalent cross-sectional areas (CSAs) in mm2. Actual cross-sections may vary slightly, depending on stranding and specific manufacturer standards.

| AWG number | Approximate cross-section (mm2) |

| 24 | 0.25 |

| 22 | 0.34 to 0.50 |

| 20 | 0.52 to 0.75 |

| 18 | 0.82 to 1.0 |

| 16 | 1.31 to 1.5 |

| 14 | 2.08 to 2.5 |

| 12 | 3.31 to 4.0 |

| 10 | 5.26 to 6.0 |

| 8 | 8.36 to 10.0 |

| 6 | 13.3 to 16.0 |

| 4 | 21.2 to 25.0 |

| 2 | 33.6 to 35.0 |

| 1 | 42.4 to 50.0 |

| 1/0 (0) | 53.5 to 55.0 |

| 2/0 (00) | 67.4 to 70.0 |

| 3/0 (000) | 85.0 to 95.0 |

| 4/0 (0000) | 107.0 to 120.0 |

How Can You Convert from AWG To mm2?

It is possible to manually convert from AWG to mm2. However, you will first need to find the diameter in mm, using the formula: dmm = 0.127 x 92(36–n)/39, where ‘n’ is the AWG gauge number.

From there, you will be able to calculate the CSA (Amm2) by using the formula for a circle: Amm2 = (π/4) x d2mm.

Alternatively, you can simply find equivalents using the AWG to mm2 wire gauge conversion calculator on the website of the electrical component supplier, RS. All that you have to do is type an AWG number into the input field, before hitting the “Calculate” button. You will then be immediately presented with the equivalent diameter in mm, and CSA in mm2.

It is crucial to note, however, that even the most reputable online calculators like the one offered by RS can only be used for general guidance purposes. Conversions may necessitate rounding, and actual performance will depend on the construction of the cable.