In furniture design and manufacturing, creativity alone is never enough. Even the most innovative concept can fail if it cannot be translated accurately into production. This is where Furniture 2D Drawing plays a decisive role. Clear, precise, and well-structured drawings are the backbone of successful furniture projects, ensuring that ideas move seamlessly from concept to fabrication without costly errors or delays.

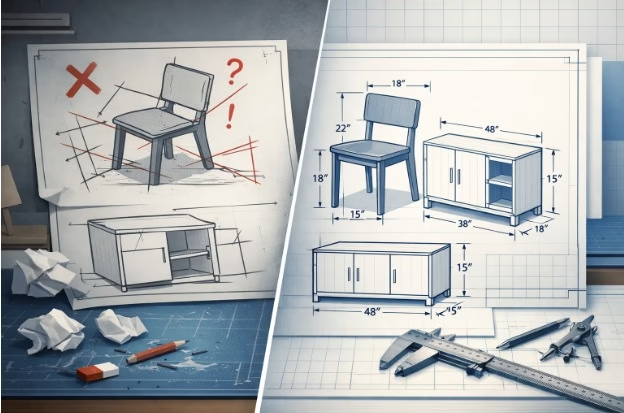

Yet many furniture professionals—designers, manufacturers, and even experienced drafters—continue to encounter avoidable problems caused by inadequate technical drawings. From incorrect dimensions to missing joinery details, these mistakes affect quality, budgets, and timelines. This article explores the most common furniture design mistakes and explains how better Furniture 2D Drawing practices help eliminate them, improving accuracy, efficiency, and communication across the entire project lifecycle.

Why Accurate Furniture Drawings Are Critical

Furniture pieces must satisfy multiple requirements simultaneously: aesthetics, ergonomics, structural integrity, material efficiency, and manufacturability. A Furniture 2D Drawing is the primary tool that brings these factors together in a format that manufacturers and craftsmen can understand.

Unlike conceptual sketches or 3D visuals, 2D drawings define exact dimensions, tolerances, construction methods, and material specifications. They serve as legal, technical, and operational references throughout fabrication. When drawings are incomplete or unclear, misinterpretation becomes inevitable—leading to rework, wasted materials, and compromised quality.

Common Furniture Design Mistakes and Their Causes

Incorrect or Incomplete Dimensions

One of the most frequent furniture design mistakes is inaccurate or missing dimensions. Designers may focus on overall size but neglect critical details such as panel thickness, spacing between components, or hardware clearances.

Common consequences include:

- Components that do not fit together during assembly

- Furniture that fails ergonomic standards

- On-site adjustments that increase labor costs

Poor dimension accuracy often results from rushed drafting or reliance on conceptual drawings rather than precise Furniture 2D Drawing documentation.

Poor Proportions and Scale Issues

Furniture that looks appealing on screen can feel awkward or uncomfortable in real life. Poor proportions—such as overly thick legs, shallow seating depth, or unbalanced casework—are often the result of insufficient technical evaluation during the drafting stage.

Without properly scaled 2D drawings, designers may overlook how individual components relate to the overall form, leading to furniture that is visually or functionally flawed.

Ignoring Manufacturing Tolerances

Wood movement, machining tolerances, and material variations are realities of furniture production. Designs that fail to account for these factors often encounter problems during fabrication or installation.

Typical issues include:

- Tight fits that crack or warp over time

- Misaligned doors and drawers

- Difficulty assembling multi-component furniture

A professional Furniture 2D Drawing includes realistic tolerances that allow manufacturers to produce consistent, durable pieces without guesswork.

Unclear or Missing Joinery Details

Joinery is central to furniture strength and longevity, yet it is frequently under-documented. Vague references such as “standard joints” or “glue and screw” leave too much room for interpretation.

When joinery details are unclear:

- Structural integrity may be compromised

- Assembly time increases

- Quality varies between production runs

Detailed technical drawings showing joinery types, dimensions, and fixing methods are essential for consistent results.

Lack of Material and Hardware Specifications

Another common mistake is failing to specify materials, finishes, and hardware clearly. Without precise documentation, manufacturers may substitute materials or select incompatible components.

This can lead to:

- Unexpected cost increases

- Visual inconsistencies

- Performance issues, such as weak fixings or unsuitable finishes

Accurate Furniture 2D Drawing standards require explicit labeling of materials, finishes, edge treatments, and hardware references.

How Better Furniture 2D Drawing Prevents These Problems

Clear Dimensioning and Annotation

High-quality Furniture 2D Drawing emphasizes clarity above all else. Every component is dimensioned logically, using consistent units and reference points. Clear annotations reduce the need for assumptions and minimize errors during production.

Effective drawings typically include:

- Overall dimensions

- Individual part sizes

- Thicknesses, offsets, and clearances

This level of precision ensures that all stakeholders interpret the design in the same way.

Scaled Views That Reveal Proportions

Multiple scaled views—plans, elevations, sections, and details—help designers and manufacturers assess proportions accurately. Seeing a piece from different angles in 2D allows for early identification of design flaws that might not be obvious in 3D renderings alone.

Well-prepared furniture drafting also supports ergonomic analysis, ensuring comfort and usability before production begins.

Defined Tolerances and Construction Logic

Professional Furniture 2D Drawing accounts for real-world manufacturing constraints. By specifying tolerances and construction sequences, drawings guide fabricators toward efficient and repeatable production processes.

This proactive approach reduces rework, minimizes material waste, and ensures long-term performance of the finished furniture.

Detailed Joinery and Assembly Information

Detailed joinery drawings remove ambiguity. Enlarged sections and callouts illustrate exactly how parts connect, what fasteners are required, and how loads are transferred through the structure.

This not only improves build quality but also helps manufacturers estimate labor accurately and streamline assembly workflows.

Comprehensive Material Documentation

Clear material and hardware specifications embedded within technical drawings prevent costly substitutions and misunderstandings. Manufacturers can source correct materials from the start, maintaining consistency across batches and ensuring the final product matches design intent.

Benefits of Accurate Furniture 2D Drawing

Investing time in high-quality Furniture 2D Drawing delivers measurable benefits across every stage of a project:

- Improved communication between designers, drafters, and manufacturers

- Reduced production errors and rework

- Better cost control and material efficiency

- Faster approvals and smoother fabrication

- Higher-quality finished furniture with consistent results

For manufacturers, accurate drawings translate directly into predictable workflows. For designers, they protect creative intent and professional credibility.

Best Practices for Creating Effective Furniture 2D Drawings

To avoid common design mistakes, furniture professionals should adopt disciplined drafting standards:

- Use consistent dimensioning systems and units throughout all drawings

- Provide multiple views, sections, and detailed callouts

- Clearly label materials, finishes, and hardware

- Include tolerances based on material behavior and fabrication methods

- Avoid overcomplication—clarity is more important than excessive detail

- Review drawings collaboratively with manufacturers before production

Whether created in CAD furniture design software or traditional drafting environments, these principles ensure drawings remain functional, readable, and production-ready.

Conclusion: Accuracy Is the Foundation of Great Furniture

Furniture design succeeds when creativity is supported by technical precision. Many costly mistakes—incorrect dimensions, weak joinery, poor proportions, or unclear specifications—stem not from bad ideas but from inadequate documentation.

By adopting professional Furniture 2D Drawing standards, designers and manufacturers can prevent errors before they reach the workshop floor. Clear, accurate drawings strengthen communication, control costs, and ensure that every piece of furniture performs as beautifully as it looks.

For anyone involved in furniture design, drafting, or manufacturing, investing in high-quality 2D drawings is not an option—it is a competitive advantage.

Meta Title:

Furniture 2D Drawing: Avoid Common Furniture Design Mistakes

Meta Description:

Learn how Furniture 2D Drawing helps prevent dimension errors, joinery issues, and production delays while improving accuracy and manufacturing efficiency.