Introduction

With the fast advancement of electronics in modern society, high speed and high frequency devices are increasingly developed. Smartphones, medical devices, satellites and communication systems all require robust circuit boards to function. This is where high frequency PCB manufacturer comes into play. Companies such as FastTurn PCB specialize in high-speed printed circuit boards that can carry fast signals without degrading them. Designing and Manufacturing High-Frequency PCBs must be done very carefully, because even slight errors may lead to a drop in ft. FastTurn PCB knows it and applies with state-of-the-art tools, highly qualified engineers and rigorous Quality Control process to obtain excellent results. By ensuring precision and reliability, they help companies make products that work smoothly and last longer. In this post, we will delve into how FastTurn PCB delivers top performance and why they are the industry trusted.

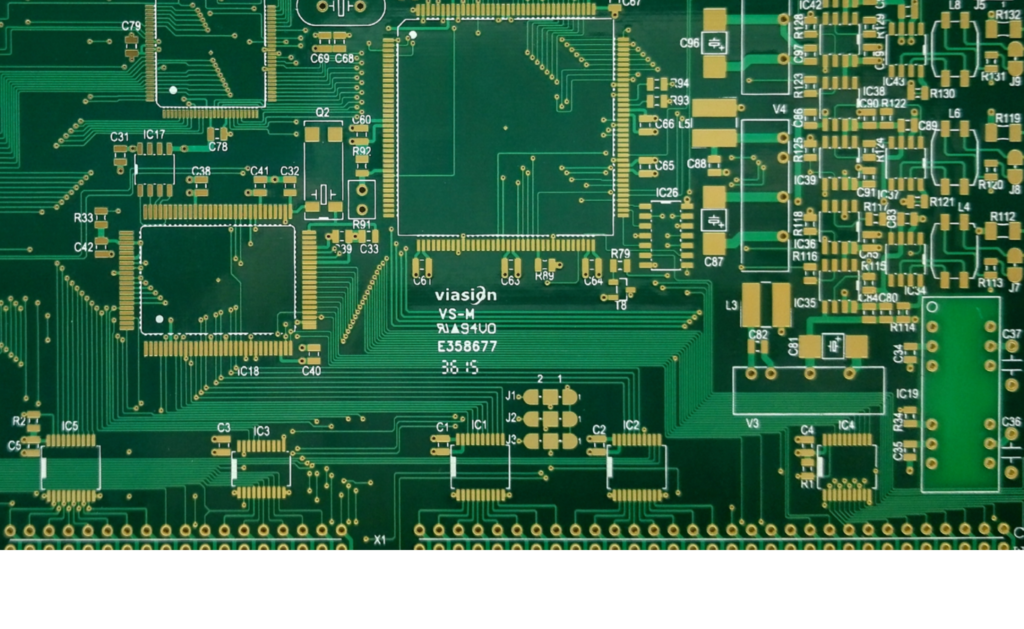

Understanding High-Frequency PCB Technology

Any high frequency PCB is unlike its well-known counterparts in a general sense. They are made to pass high-speed signals with little loss, noise or other interference. They find application in wireless equipments, radar systems and high-speed communications links. A quality high frequency PCB manufacturer is going to have a good understanding of how signals work at higher speeds. FastTurn PCB reviews things such as signal integrity, impedance and electromagnetic compatibilities before it begins production. They are made of special materials that would less signal loss and assure stabililty. Their engineers meticulously design out every trace and connection to ensure that there are no dirty, noisy、or weak signals. FastTurn PCB knows how electricity travels through the board, which means being able to sidestep issues such as distortion and overheating. Their extensive technical know-how allows them to create PCBs that are durable even under sustained use. The result is products that are dependable and prepared for challenging applications.

Using Advanced Materials for Better Performance

The quality of materials is a big factor in PCB performance. Special substrates are necessary for high-frequency circuits that can accommodate such rapid signals without breaking down. FastTurn PCB has superior quality materials like PTFE, ceramic etc to choose from. These allow for exact signal transmission and minimal energy loss. FastTurn PCB, a reliable high frequency PCB manufacturer and supplier, is definitely not an exception. They are partnered directly with reliable suppliers to provide quality products. These high technology materials also provide superior heat resistance and extended life. This makes the PCB able to operate in extreme environments without degradation of efficiency. And, by using top quality materials in production, FastTurn PCB assists customers to reduce lifetime costs of repairs and system failures. One of the reasons for their excellent performance is in fact their judicious choice of material.

Precision Design and Engineering Process

Base material is the basis of high speed PCB. A bad layout cannot be fixed with the best materials. FastTurn PCB employs sophisticated design software and experienced engineers to develop precise layouts quickly. They take your trace width, your spacing and the layup into account while designing. A professional high frequency PCB manufacturer is aware that little design inconsistencies can have major implications later on. FastTurn PCB simulates and tests ALL lay-outs prior to releasing it for production. This helps catch weaknesses early. Their team also collaborates with clients in order to comprehend project needs. They blend customer input with technical acumen to produce optimal designs. Such careful preparation is intended to reduce signal degradation and to enhance durability. FastTurn PCB concentrates on precision manufacturing, and makes sure every board produced lives up to high industry performance standards.

State-of-the-Art Manufacturing Equipment

High-Level Equipment is a Must for Manufacturing Good PCBs A good number of modern equipment are necessary to produce high level PCBs. FastTurn PCB Introduces State of the Art Equipment for High Precision and Quality Production. From laser drilling to automated soldering systems – each stage is computer directed. A Professional High frequency PCB Manufacturer need keep strict tolerance.FastTurn PCB takes it easily. Their machines can manage complex multi-layered board and extremely small devices without mistake. Board function is also tested on every board during production by machine inspection systems. It minimizes human errors and gets a better quality overall. Proper maintenance of instrument is crucial to ensure it functioning well and result consistency. FastTurn PCB can manufacture high quantity without compromising on precision by using the most advanced tools. They prefer this compromise between speed and quality.

Strict Quality Control and Testing Standards

PCB Manufacturing And Quality Control Testing One of the essential aspects of PCB manufacturing is quality control. FastTurn PCB is also under tight examination and testing process throughout each stage. Every board is electrically tested, for signal stability and physical strength. Only an experienced high frequency PCB manufacturer will not overlook the strict quality check procedure and we do take it quite seriously here at FastTurn PCB. They rely on AOI, X-ray inspection and functional testing to find hidden defects. All results are reviewed by their quality team before products are released for shipment. This comprehensive process is part of Building Quality into every board, and assists to eliminate potential bad boards reaching customers. It also builds long-term trust. FastTurn PCB guarantees that all PCBS function properly by having high-testing standards. Their emphasis on quality minimizes ’failures’ and maximises customer satisfaction.

Fast Turnaround Time and Customer Support

Nowadays speed is very crucial, in a competitive market. Companies want fast delivery without any drop in quality. In addition, FastTurn PCB is renowned for quick turns and dependable service. As one of the best high frequency PCB suppliers, they combine rapidity and precision. They have good productivity and experienced workers that enable them to fulfill orders in time. They are strong on customer support throughout the project also. Designs can be discussed, changes requested and progress tracked with ease by clients. FastTurn PCB keeps you informed with open communication and status updates. This reduces confusion and delays. Their staff of developers and engineers assists customers in selecting the appropriate materials and processes, while their support team works to meet lead times. With fast delivery and good service, FastTurn PCB makes strategic cooperation with customers. Their customer-centricity is a huge value add to their product competency.

Conclusion

FastTurn PCB has developed an impressive reputation by delivering on quality, technology and customer requirements. As a reliable high frequency PCB supplier and service provider, they know how hard the life is for high speed electronics. From high-precision design, to rigorous testing and fine tuning by skilled engineers, each step in the process is carefully performed. Moreover, short circular time of replica exchange MET mum and powerful support system enhance their reliability. These investments and efforts make certain that our customers get superior PCBs that perform better and outlast others. In an environment where electronic systems are getting more and more in-depth, companies require partners on whom they can rely. FastTurn PCB takes pride in maintaining our commitment and focus on Innovation, Precision Quality, On-Time Delivery and 100% Customer Satisfaction. This is what makes them perfect for certain businesses that depend on tailored high-frequency PCBs.