Whether you’re planning a large commercial project or need precision metalwork for industrial equipment, choosing the right welding and fabrication contractor is a critical decision. The quality of the welds, the accuracy of cuts and assemblies, and the contractor’s ability to deliver on time can significantly impact your project’s success. Asking the right questions before signing a contract ensures you partner with a contractor who offers the right skills, capabilities, and reliability for your needs.

1. What Is Your Experience With Projects Like Mine?

One of the first questions you should ask is whether the contractor has direct experience with projects similar to yours. Welding and fabrication encompass a wide range of materials, techniques, and end uses. A contractor with relevant experience is more likely to understand the nuances of your project’s requirements and avoid costly mistakes. Asking for examples of past work or case studies helps you gauge their expertise and confidence.

2. What Certifications and Standards Do You Follow?

Quality and safety are crucial in welding and fabrication, especially for structural or load-bearing applications. Contractors who follow recognized industry standards are more likely to produce consistent, high-quality results. Certifications also indicate that the contractor’s welders have undergone formal testing and are qualified to perform specific types of work. Inquiring about their adherence to standards and certifications gives you confidence that the work will meet industry expectations.

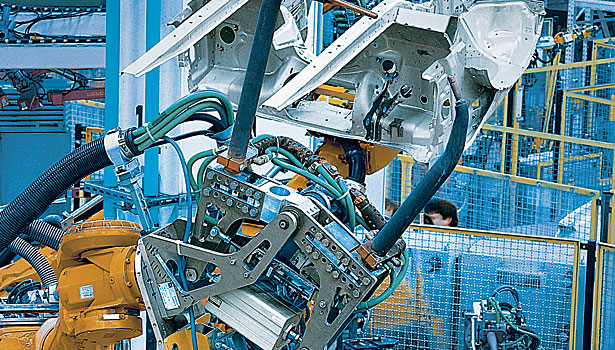

3. What Equipment and Technology Do You Use?

Modern welding and fabrication rely on advanced tools and equipment to ensure precision, repeatability, and efficiency. Ask potential contractors about their machinery, fabrication technology, and whether they use automated systems like CNC cutting, robotic welding, or laser cutting. A well-equipped shop can minimize human error, reduce material waste, and deliver better overall quality. Understanding their technological capabilities also helps you determine if they’re equipped to handle the scale and complexity of your project.

4. How Do You Ensure Quality Control?

Quality control is where good contractors set themselves apart. There must be a process in place to check weld integrity, dimensional accuracy, and compliance with specifications. Ask about their quality assurance practices: Do they perform inspections during and after fabrication? Do they use non-destructive testing (NDT) or other verification methods? Understanding how they manage quality helps you avoid surprises down the line and ensures the final product meets your standards.

5. Can You Provide References and a Project Timeline?

Before you commit, ask for references from past clients, especially those with similar projects. Speaking with others who have worked with the contractor can reveal insights into communication, reliability, and overall satisfaction. Additionally, request a clear project timeline and understanding of how the contractor handles deadlines and potential delays. A responsive, organized welding and fabrication professional should be able to map out stages of work and give you realistic expectations.

Conclusion

Hiring the right welding and fabrication contractor requires more than just comparing prices. By asking thoughtful, targeted questions about experience, credentials, equipment, quality control, and references, you protect your investment and set your project up for success. Taking the time to vet potential partners thoroughly ensures you get the quality, safety, and performance your build demands.