Steel washers play an often understated yet crucial role in the vast landscape of industrial components. These components, typically resembling thin plates with a central hole, are indispensable in numerous applications for distributing load, preventing surface damage, ensuring tightness, and providing insulation.

The past few decades have witnessed remarkable advancements in material science, which have significantly enhanced the performance and durability of washers, especially those crafted from various steel alloys.

This aims to delve into these advancements, shedding light on how modern technology has revolutionized these critical components, making them more than just simple hardware pieces.

Historical Perspective and Evolution

From their inception, washers have evolved considerably both in design and material. Initially, washers were made from wood and leather, serving elementary functions in simpler mechanisms.

However, the onset of the Industrial Revolution catalyzed a major shift towards more durable materials, with steel becoming a prime choice. This transition marked a significant development in the manufacturing of washers.

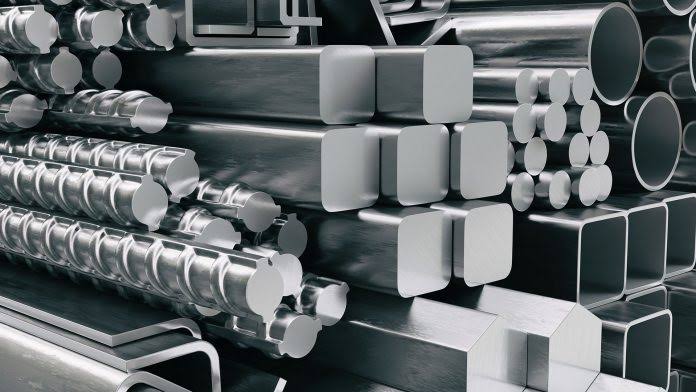

From simple designs to more sophisticated forms, steel emerged as a key material, particularly variants like carbon steel washers and 316 stainless steel washers.

These materials offered enhanced strength, durability, and resistance to environmental factors, meeting the demanding industrial requirements of the time.

This period of innovation laid the groundwork for the diverse range of washers available today, including stainless steel square washers and square steel washers, each serving specific purposes in various industrial applications.

A notable player in this field is Superior Washer & Gasket Corp, renowned for its commitment to quality and innovation. They utilize advanced technologies to manufacture various washers, including specialized forms like stainless steel square washers and square steel washers.

This precision in manufacturing ensures uniformity in size and shape, significantly enhancing the washers’ performance in various applications. Visit their website to learn more about their range of high-quality washers.

Enhanced Material Properties

Advances in washer performance can be largely attributed to material scientists’ development of superior steel alloys. These specialized steel compositions offer optimal properties for different applications.

For example, 316 stainless steel washers are known for their exceptional corrosion resistance due to their high chromium and nickel content. This makes them ideal for use in harsh environments, such as marine settings or chemical processing plants.

Conversely, carbon steel washers are characterized by their high carbon content, which imparts increased hardness and strength. These properties make them suitable for heavy-duty applications where robustness and load-bearing capacity are paramount.

This diversification in steel types has allowed for the development of a range of washers, each tailored to meet specific environmental and mechanical demands.

Significant improvements in manufacturing processes have been made in tandem with material advancements. Precision engineering techniques, such as CNC machining and laser cutting, have produced washers with exact specifications.

Application in Various Industries

The application of washers crafted from advanced steel alloys in various industries underscores their critical importance. These vital components significantly ensure safety, efficiency, and longevity across various mechanical systems.

In construction, their role is pivotal. Used to evenly distribute the load of threaded fasteners like bolts and screws, they prevent surface damage and maintain structural integrity, especially in high-stress environments such as skyscrapers or bridges.

Their ability to reduce vibration and provide insulation also helps prevent bolts from loosening over time, a crucial factor in ensuring long-term structural stability.

The automotive industry relies heavily on these components for maintaining tight connections, crucial for vehicle performance and safety. They are integral in engine assemblies and braking systems, where enduring high-pressure conditions and preventing fluid leakages are essential.

Their role in evenly distributing loads extends the lifespan of various automotive parts.

These washers are indispensable for heavy machinery and equipment used in mining, agriculture, and manufacturing industries.

Operating under extreme conditions, including high pressures and temperatures, their role in maintaining the integrity of bolted joints is vital for operational safety and preventing equipment breakdowns.

These components also greatly benefit the aerospace and shipping sectors. In aerospace, they are used in constructing and maintaining aircraft, where precision and reliability are paramount.

Their ability to secure fastenings in environments experiencing dramatic pressure and temperature shifts is critical. Certain types, like 316 stainless variants, are favored in marine environments for their corrosion resistance, which is essential for the longevity of ships and marine equipment.

In electronics, these washers prevent electromagnetic interference and secure delicate components. Their conductive properties make them suitable for grounding applications, ensuring the safe operation of electronic devices.

The selection of the appropriate type—be it carbon steel, square, or other variants—is influenced by factors like environmental conditions, contact materials, and mechanical demands.

This wide range of applications highlights the versatility of these washers and emphasizes their indispensable role in modern industry.

They are integral to the reliability and safety of many machines and structures central to daily life and the economy. The continuous advancements in material science and manufacturing will further enhance the capabilities of these components, meeting the evolving demands of diverse industries.

Sustainability and Environmental Considerations

The manufacturing of steel washers has increasingly aligned with sustainable and environmentally responsible practices. Steel’s inherent recyclability is a significant advantage, promoting eco-friendly production processes.

The modern manufacturing methods for steel washers have become more energy-efficient, and the use of recycled materials is now commonplace. This approach mitigates the environmental impact and ensures the sustainability of the washer manufacturing industry.

By embracing these eco-friendly practices, manufacturers contribute to environmental conservation and ensure a sustainable supply chain that supports various industries reliant on these components.

Future Trends and Innovations

The promise of continued innovation and development marks the future of washer technology. Material scientists are exploring new steel alloys with enhanced properties, such as higher strength-to-weight ratios and improved corrosion resistance.

These developments are poised to further refine steel washers’ efficiency and durability. Integrating advanced manufacturing technologies, such as automated quality control and additive manufacturing (3D printing), will revolutionize washer production.

These innovations will enable the creation of washers with intricate designs and customized specifications, expanding their applicability in various industrial sectors.

The evolution of washers from basic mechanical spacers to sophisticated and highly engineered components reflects the remarkable progress in material science and manufacturing technology.

Advances in steel alloys and production techniques have enhanced the performance of these essential components and broadened their application across many industries.

The future of washer technology, buoyed by ongoing innovation in material science, holds great promise for more efficient, durable, and sustainable industrial solutions.