Rust, the reddish-brown oxide that forms on metal surfaces, is scientifically known as iron oxide. It occurs when iron or steel reacts with oxygen in the presence of moisture. This natural process can weaken metal parts, shorten their lifespan, and impair their functionality. Fortunately, there are several effective strategies to prevent rust and maintain metal components in excellent condition. Below, we explore reliable methods to keep rust at bay.

What is Rust?

Rust is a type of iron oxide that forms when iron combines with oxygen and moisture. It appears as an orange-brown discoloration, most commonly seen on metal surfaces, and affects both pure iron and iron alloys like steel. Water is the primary catalyst for rusting. Though metal structures may look solid to the naked eye, tiny water molecules can seep into microscopic pores, triggering corrosion. This process speeds up if the water contains salt or if the metal is exposed to carbon dioxide and sulfur compounds.

Keep Metals Dry

The simplest way to prevent rust is to keep metal equipment away from excessively wet environments. Since water reacts with iron and oxygen to form rust, a moisture-free setting can significantly reduce rusting. However, even regular air contains water vapor—known as humidity—which makes eliminating moisture challenging. For equipment to remain rust-free indefinitely, it would need to be sealed airtight, rendering it unusable. That said, sealing metal items during storage or transport is a practical way to protect metals from rust when they’re not in use.

Opt for Corrosion-Resistant Alloys

All metals corrode eventually, but some do much more slowly than others. Alloys, which combine two or more metals, can be engineered for greater rust resistance. All steel is an alloy of iron and carbon, but adding elements like nickel, chromium, or manganese creates specialized steel alloys with unique benefits. For example:

Stainless Steel: Designed to resist rust, it contains chromium, which forms a protective layer of chromium oxide. While not entirely corrosion-proof, it rusts far more slowly.

Weathering Steel: This alloy rusts initially but then forms a stable layer that halts further corrosion under the right conditions.

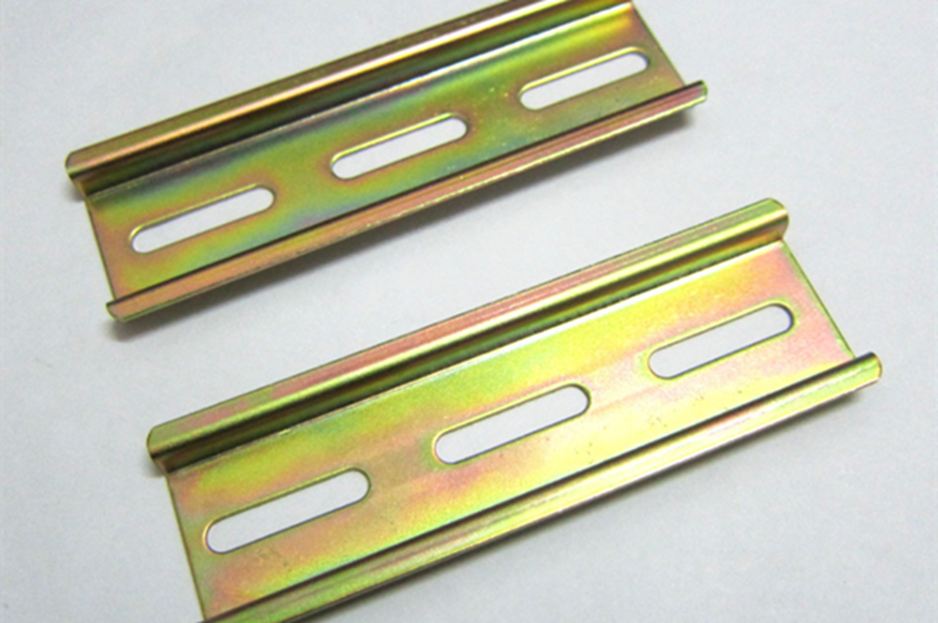

Use Protective Coatings

One of the most effective ways to prevent metals from rusting is by applying a protective coating to metal surfaces. These coatings create a barrier that blocks oxygen and moisture from reaching the metal underneath. Popular options include:

Powder Coating: This involves applying a dry powder that’s cured with heat. Dry powder is evenly applied to a clean metal surface. Then, the metal is heated to form a thin protective film. Nylon, polyurethane, acrylic, and polyester can all be used.

Zinc Plating: Coating steel or iron with a thin layer of zinc, offering excellent protection. Zinc will corrode first and sacrifice itself to shield the base metal.

Try Blackening

For smaller steel parts, a process called blackening can offer effective rust protection. This involves immersing the steel in a solution of potassium nitrate, sodium hydroxide, and water, which produces a blue or black finish—hence the name. While not as robust as other methods, it’s a viable option for specific applications.

Apply Oils or Greases

Using organic coatings like oils or greases is an economical and highly effective way to protect metal from rust. These substances form a barrier that seals out corrosive elements like oxygen and water. Options include:

Oils: Traditional mineral oils or synthetic lubricants flow through mechanical systems, coating components with a thin, protective film that isolates them from air and moisture.

Greases: Made from oil with added thickeners, greases are stickier and more viscous, allowing them to stay in place longer for extended protection.

Rust Inhibitors: These advanced solutions, often petroleum- or mineral-based, include special additives that enhance their rust-preventing power.

Conclusion

Rust may be a persistent threat to metal parts, but with the right strategies, it’s entirely manageable. Whether you opt for protective coatings, corrosion-resistant alloys, or simple moisture control, each method offers a practical way to extend the life of your metal components. By choosing the approach that best suits your needs, you can keep rust at bay and ensure your equipment remains strong and functional for years to come.