Engraving is an age-old craft that combines artistry and precision, evolving over millennia from primitive stone carvings to the sophisticated laser technology we see today. Whether you’re a hobbyist looking to add a personal touch to a handcrafted gift, a small business owner producing branded merchandise, or an industrial designer applying permanent markings to products, the key to producing high-quality results lies in choosing the right engraving tool. However, there is no single “best” tool that fits all projects because different materials, project sizes, and design complexities demand different approaches. Understanding how various engraving tools operate, where each excels, and how to use them effectively will empower you to achieve flawless, professional-grade engravings every time you work on a new project.

Types of Engraving Tools and Their Applications

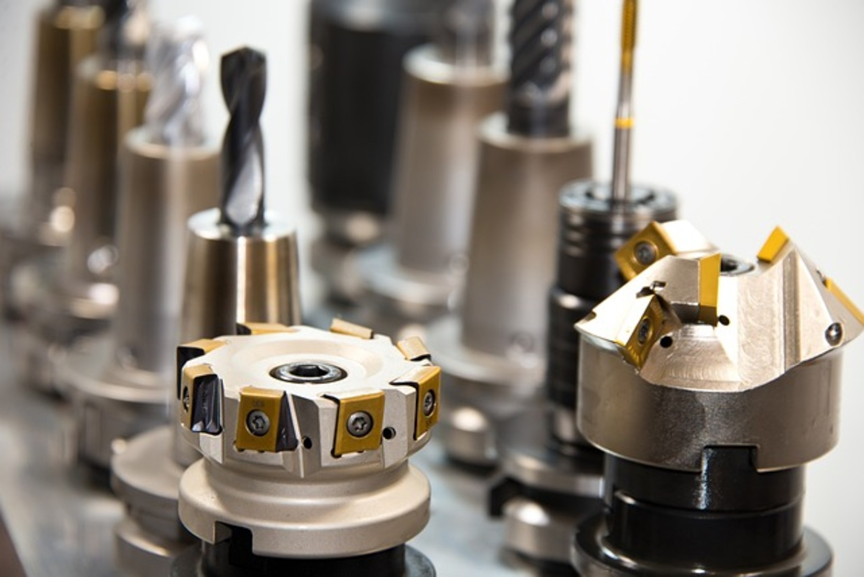

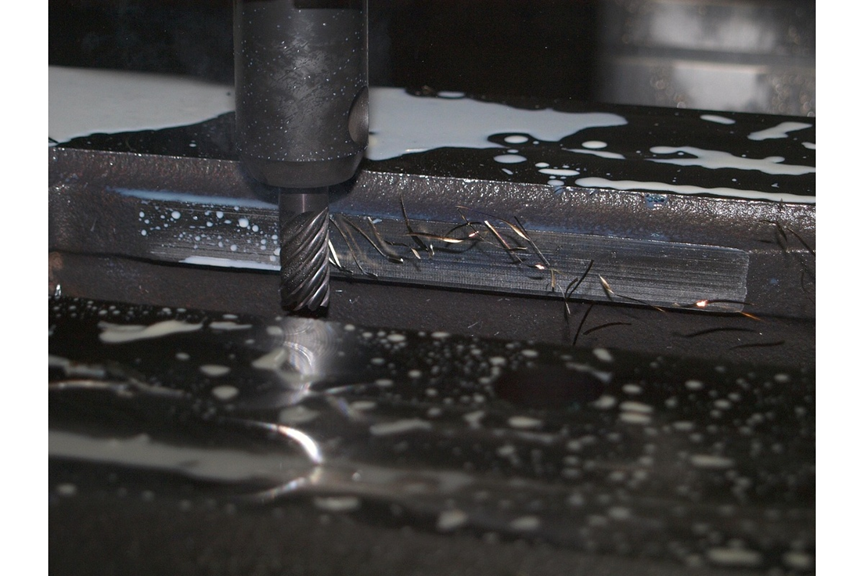

Today, a broad spectrum of engraving tools is available to suit virtually any creative or industrial need. Traditional manual tools such as chisels, gravers, and burins remain favored by jewelers and fine artists for their unparalleled control and precision. These tools excel at producing delicate lines and intricate patterns, offering a tactile experience that automated machines cannot replicate. However, they require significant skill, patience, and time to master, making them more suitable for artists or craftspeople who value handcrafted details. On the other hand, electric engraving tools, including handheld engraving pens, offer speed, convenience, and portability. They work wonderfully on softer materials like wood, leather, acrylic, and some softer metals, making them ideal for DIY projects, craft fairs, or small workshop settings. Their ease of use makes engraving more accessible to beginners or those who need quick results without extensive training. For those who demand the highest level of precision and repeatability, laser engraving tools represent the current pinnacle of engraving technology. CO₂ laser engravers are particularly effective on organic materials such as wood and leather, delivering smooth, clean marks without physical contact. Fiber laser machines specialize in metals, engraving detailed, permanent designs that can withstand wear and corrosion. CNC engraving machines, which combine computer numerical control with engraving tools, bring industrial-scale accuracy and volume, capable of producing consistent, complex designs efficiently in commercial manufacturing settings. Whether you need a compact electric engraver for personalized gifts or a large CNC machine for bulk production, the wide array of tools available ensures there is a perfect fit for your goals.

Choosing the Right Engraving Tool for Your Needs

Choosing the right engraving tool starts with understanding your primary material and project requirements. Wood, acrylic, and leather generally respond well to electric and laser engraving tools, yielding smooth finishes with minimal need for post-processing. Metals such as stainless steel, aluminum, and brass require more specialized equipment, often relying on high-power fiber lasers or manual tools with carbide tips designed to withstand the hardness of these surfaces. The complexity of your design also influences the choice: finely detailed, small-scale patterns benefit greatly from precision tools like laser engravers or hand gravers, while larger signs or repetitive branding jobs are more efficiently handled by CNC machines or industrial laser systems. Budget is another major consideration; manual engraving tools tend to be the most affordable but come with a steep learning curve and longer production times. Electric engraving tools strike a balance between cost and convenience, offering a relatively low investment for moderate precision and versatility. Laser engraving machines represent a significant upfront expense but deliver unmatched accuracy, speed, and flexibility, often paying off in professional or industrial environments. Your available workspace plays a critical role, too. Portable engraving pens can be used nearly anywhere, perfect for mobile artists or casual hobbyists, whereas larger machines like CNC routers or laser engravers require dedicated space, proper ventilation, and stable power supply.

Tips for Effective Engraving

To get the most from your engraving tool, technique is as important as the tool itself. Start by practicing on scrap materials to understand how your tool behaves on different surfaces. Ensuring your workpiece is securely fixed prevents slips that can ruin your project or cause injury. Applying steady, controlled pressure rather than forcing the tool results in cleaner, more precise lines. For electric and laser engraving tools, experimenting with speed and power settings helps you find the optimal balance between depth, clarity, and material integrity. Regular maintenance is key—keeping bits, blades, and laser lenses clean and sharp greatly enhances performance and prolongs tool life. Always work in a well-ventilated area, especially when engraving materials that release dust or fumes, and wear protective eyewear and gloves to ensure safety.

Safety and Maintenance

Safety is paramount regardless of the engraving tool you use. Manual tools require careful handling to avoid cuts or punctures, while electric and laser tools introduce additional hazards such as high speeds and potentially harmful beams. Protective goggles, gloves, and securing loose clothing or hair are essential precautions. For laser engraving, following manufacturer safety instructions is critical to avoid exposure to harmful beams and fumes. Maintenance includes cleaning your tools after each use, lubricating moving parts when necessary, and replacing worn bits or blades. Laser engravers need regular lens cleaning and calibration, while CNC machines benefit from software updates and alignment checks to maintain precision. Proper storage in a dry, dust-free environment will also extend your tools’ lifespan and keep them ready for future projects.

The Future of Engraving

Looking ahead, engraving tools are becoming more portable, automated, and intelligent. Battery-powered tools allow creators to work wherever inspiration strikes, while AI-assisted design software makes complex patterns accessible even to beginners. Laser engraving machines are shrinking in size and cost, enabling professional-quality work in home workshops and small studios. Sustainability is increasingly influencing the industry, with eco-friendly materials and energy-efficient machines gaining popularity. These trends make engraving more accessible, versatile, and environmentally conscious than ever before.

Conclusion

Ultimately, choosing the right engraving tool means matching your creative vision and project needs with the appropriate technology. Whether you prefer the tactile finesse of traditional hand gravers or the cutting-edge precision of laser machines, understanding your materials, design complexity, budget, and workspace will guide you toward the ideal tool. With consistent practice, careful maintenance, and openness to new technologies, you can transform everyday surfaces into stunning, lasting works of art that showcase your skill, creativity, and precision.