In busy packaging rooms, speed, accuracy, and the ability to adjust on the fly can make or break a production run. That is especially true when you are packaging liquids, because every change in viscosity raises new engineering and workflow questions.

Whether you are dealing with thin water or sticky shampoo, each product behaves differently as it leaves the bottle. A liquid filling machine therefore needs to match flow behavior while also guarding against contamination, meeting fill-weight targets and keeping the line moving.

For companies that plan to grow or switch formats, picking the right custom packaging machine early on can save time and money later. The following sections break down how modern liquid fillers handle wide viscosity ranges and outline key points managers should consider before buying.

Why Viscosity Matters in Liquid Filling Operations

Simply put, viscosity tells you how easily a liquid pours. A substance with high viscosity, like honey or laundry gel, flows much slower than low-viscosity liquids such as water or vodka. That difference affects the choice of filling valves, pump types, speed settings and even container construction.

In any high-speed bottling line, differences in how thick a liquid is can affect the fill speed, the type of nozzle you need, and even the pump you choose. If the machines and parts you pick are not matched to the products, you could end up with spilled batches, a fill that varies from bottle to bottle, excessive foaming, or hours of downtime so costly you can’t ignore them.

Most drinks and household liquids can be roughly sorted into three thickness ranges, or viscosity categories:

- Low viscosity: water, juice, wine

- Medium viscosity: cooking oil, liquid soap, syrup

- High viscosity: honey, shampoo, detergent, creams

Each group calls for a different hardware setup. Modern filling lines tackle this by combining piston fillers, gravity fillers, peristaltic heads and other technologies into one custom packaging machine that matches the needs of each specific product.

Common Filling Technologies for Different Viscosities

To keep fills accurate and to cut drips, splashes, or unwanted bubbles, plant engineers lean on several well-proven methods. Which one they pick depends on how thick the liquid is, what kind of container it comes in, and how fast the line has to run.

Gravity Fillers for Low-Viscosity Liquids

Gravity fillers let the fluid flow downward into bottles, working at the speed of free fall. That makes them a great choice for:

- water, wine, and fruit juice

- any thin liquid that needs fast fills

- clean areas where you want parts to stay untouched as much as possible

They are low-cost and easy to maintain, but because they push nothing, they fall short with thick pastes or foamy, bubbly items.

Overflow Fillers for Foam Control

When bottling low- or medium-thick liquids that froth easily-shampoos, cleaners, or similar items-overflow fillers shine. By letting any tiny volume change spill over, these machines ensure every container looks topped to the same line.

Piston Fillers for Medium to High Viscosity Products

Piston fillers rank among the most flexible and popular options for thicker goods like-

- Creams, lotions, sauces, pastes

- Detergents and sticky chemicals

- Peanut butter and syrups

A sliding piston pulls a set volume into a chamber and then forces it through a nozzle into the jar or bottle. Because they stay accurate and adjust easily, they keep appearing in custom packaging setups that handle varied product lines.

Pump Fillers for Flexible Control

Pump fillers-gear, peristaltic, and lobe designs-give operators tight control over how fast and how much liquid comes out. People reach for these when filling-

- High-end or fragile products

- Shear-sensitive liquids such as cosmetics or lab samples

- Lines with fast-switching jobs and different viscosities

Their bolt-on look means B2B factories can swap parts instead of whole machines, making them a top pick for companies that package many items on the same line.

Adapting to Container and Cap Types

When setting up a filling line, viscosity is only half the story. Container shape, size, and material also steer how the machines are built. Bottles, pouches, jars, and jugs each need their own handling action and nozzle angle to fill cleanly and accurately.

For example:

- Tall, narrow bottles may need diving nozzles to prevent splashing.

- Wide-mouth jars may require multiple fill heads or wider pistons.

- Flexible pouches often benefit from custom-formulated nozzle angles and speeds.

Because of these differences, a liquid-filling machine and a custom packaging machine should be designed together. That way, the machine settings match the product and container every time. Private-label businesses and companies that launch seasonal items gain the most from this close match.

Integration, Customization, and Automation Benefits

Filling is just one step. Producers want a smooth system that moves through:

- Container feeding

- Filling

- Capping

- Labeling

- Coding

- Inspection

- Packing

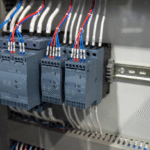

That’s the job of a custom packaging machine. Many B2B buyers ask for modular lines they can add to later or switch for new products. Today, features like remote diagnostics, IoT links, and Industry 4.0-readiness come as standard, not extras.

A fully integrated filling line streamlines operations, bringing several clear advantages:

- Less labor hours and reduced machine downtime

- Faster switchovers between product or container types

- More consistent fill volumes and tighter quality control

- Easier cleaning thanks to built-in CIP (Clean-In-Place) systems

- Remote monitoring that flags maintenance needs before they disrupt production

Lines like this shine in fast-moving industries such as personal care, chemicals, and food and drink, where product variety is high yet compliance rules are unyielding.

What B2B Buyers Should Keep in Mind

When picking a liquid-filling line, manufacturers need to balance today’s demands with tomorrow’s growth. The following questions help clarify those requirements:

- What viscosity range will the line handle?

- Are any products foamy, corrosive, or sensitive to shear?

- How many container sizes are regularly run?

- What output do you need each shift?

- Is tool-less changeover or quick cleanup a must?

- Will the new line mesh with existing upstream and downstream machines?

Trusted custom machine makers not only sell equipment; they also deliver technical support, operator training, and ready spare parts—critical back-up for any high-speed B2B operation.

Conclusion

Whether you fill bottled water or heavy-duty industrial detergents, liquid filling machines need to be designed for a wide mix of thickness, bottle shape, and output goal. To keep your line running smoothly, pick gear that fits your product and your plan for how much you want to produce.

For most B2B companies that chase speed, safety, and room to grow, choosing a liquid filling machine along with a custom packaging solution delivers steady output, quicker time-to-market, and fewer slowdowns.

As customers ask for more volume and greater switch-over ease, having the right equipment on the floor will often separate the market leaders from the rest.