The manufacturing sector produces a wide range of goods, from food and textiles to machinery and vehicles. However, this industry is filled with workplace health and safety risks. According to the Office for National Statistics (ONS) Labour Force Survey, 33,000 manufacturing workers annually experience job-related illnesses. Manufacturers must implement safety measures to protect their employees and others from harm.

This guide highlights manufacturers’ role and the importance of safety in the manufacturing industry. It also covers the potential risks workers face and strategies to mitigate them, including essential training for workers.

What is The Role of a Manufacturer?

Manufacturers play a pivotal role in the economy, converting raw materials into finished products to meet consumer needs and market demands. They are also responsible for ensuring the quality of products and compliance with regulations.

Manufacturers are responsible for ensuring the safety and well-being of their workforce by creating a safe working environment, adhering to legal safety standards and continuously seeking ways to minimise occupational hazards.

Why is Safety Important in the Manufacturing Industry?

Safety in manufacturing is not just a regulatory requirement; it’s a fundamental component that impacts every aspect of the operation. A safe work environment protects employees from accidents and injuries and enhances productivity by fostering a culture of care and respect. It also minimises costly downtime and reduces risks of legal liabilities.

What Are The Health and Safety Risks in the Manufacturing Sector?

The manufacturing sector is fraught with hazards, varying significantly across different industries. Common risks include:

- Chemical Exposure: In manufacturing plants, workers handle various chemicals, from solvents to adhesives. Proper handling, storage and protective gear are crucial to prevent exposure and related health issues.

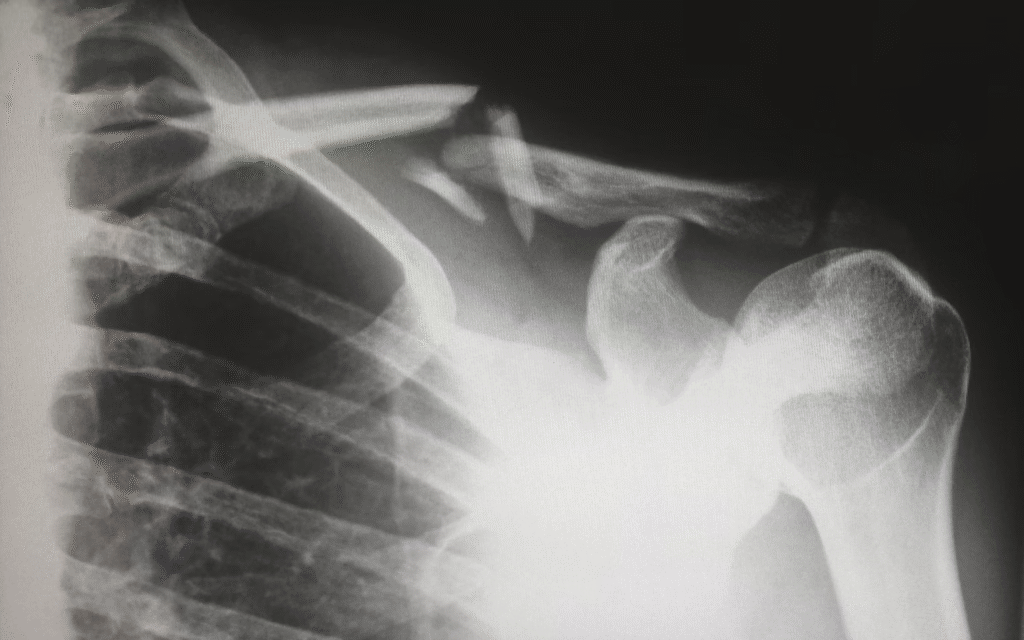

- Machinery Accidents: Machinery and equipment in manufacturing pose risks if not operated correctly or maintained. Proper guarding, training and maintenance are essential for worker safety.

- Noise: Manufacturing environments can be noisy, leading to hearing impairment. Implementing noise control measures and providing hearing protection training are crucial to protect workers’ hearing.

- Manual Handling Risks: Manufacturing tasks like lifting and repetitive motions can cause musculoskeletal disorders. Ergonomic assessments and training on proper techniques help prevent injuries.

- Fires and Explosions: Manufacturing processes involving flammable materials increase the risk of fires and explosions. Adequate storage of these materials and providing fire safety training to employees are crucial for preventing such incidents.

How to Ensure the Health and Safety of Workers?

Here’s how manufacturers can ensure the health and safety of workers:

- Risk Assessment: Conduct regular risk assessments to identify potential hazards, evaluate their likelihood and severity and implement measures to minimise risks.

- Safety Protocols: Establish and implement safety protocols that outline clear guidelines for safe equipment operation, material handling and emergency response procedures. Protocols should be clear, accessible and reinforced through continuous training.

- Emergency Preparedness: Plan for unforeseen events such as fires or medical emergencies. Establish clear evacuation routes, conduct regular drills and ensure accessible emergency exits.

- Maintenance: Regularly maintain machinery safe operation. Perform routine checks, ensure timely repairs, and update maintenance records.

- Personal Protective Equipment (PPE): Provide appropriate PPE and training to reduce injury risks. Regularly check and replace PPE when needed.

What Training Should Workers in Manufacturing Take?

Training empowers workers with the knowledge and skills to perform their jobs safely. Here are some of the essential health and safety training for manufacturing workers:

- First Aid and CPR

This training equips workers with skills to provide immediate care in case of a medical emergency until professional help arrives. It teaches them first aid techniques, CPR and AED use.

- Chemical Safety Training

Chemical safety training educates employees on properly handling, storing and disposing of hazardous chemicals to prevent accidents and ensure a safe working environment.

- Machine Safety

Machine safety training addresses risks associated with operating machinery and equipment. It includes instructions on using guards and safety devices, following lockout/tagout procedures to ensure machines are safely shut off during maintenance and recognising the signs of equipment malfunction.

- Noise Awareness Training

Noise awareness training raises awareness among workers about the risks of excessive noise exposure and provides strategies to protect hearing health through the use of personal protective equipment and engineering controls.

- Manual Handling Training in Industry

Manual handling training in industry teaches safe lifting, carrying and moving techniques to prevent injuries, especially to the back. It includes risk assessment and equipment use and emphasises body mechanics and ergonomics for minimising risks.

- Fire Safety Training

Fire safety training equips employees with essential knowledge and skills to respond effectively to fire emergencies, including evacuation procedures, fire extinguisher usage and prevention techniques.

- Risk Assessment Training

The risk assessment training course teaches employees to identify and evaluate potential hazards in their work environments. It also educates them on ways to control these hazards to promote a safe work environment.

Conclusion

A safe manufacturing environment results from careful planning, continuous training and a shared commitment to well-being. Manufacturers can create a workplace where safety is integrated into daily operations by understanding the risks, implementing robust safety protocols and ensuring comprehensive worker training.