You’ve probably seen it before: equipment sitting idle on a jobsite while everyone waits for shop support to arrive. Those delays can throw off grading, trenching, or even an entire day’s schedule.

The good news? On-site oil change support and other mobile lube setups are giving crews a way to keep work moving.

In this article, we’ll show how field teams use mobile lube to close the gaps. We’ll explain why that matters on construction jobs. And, we’ll share options that make sense when the shop can’t get there fast enough.

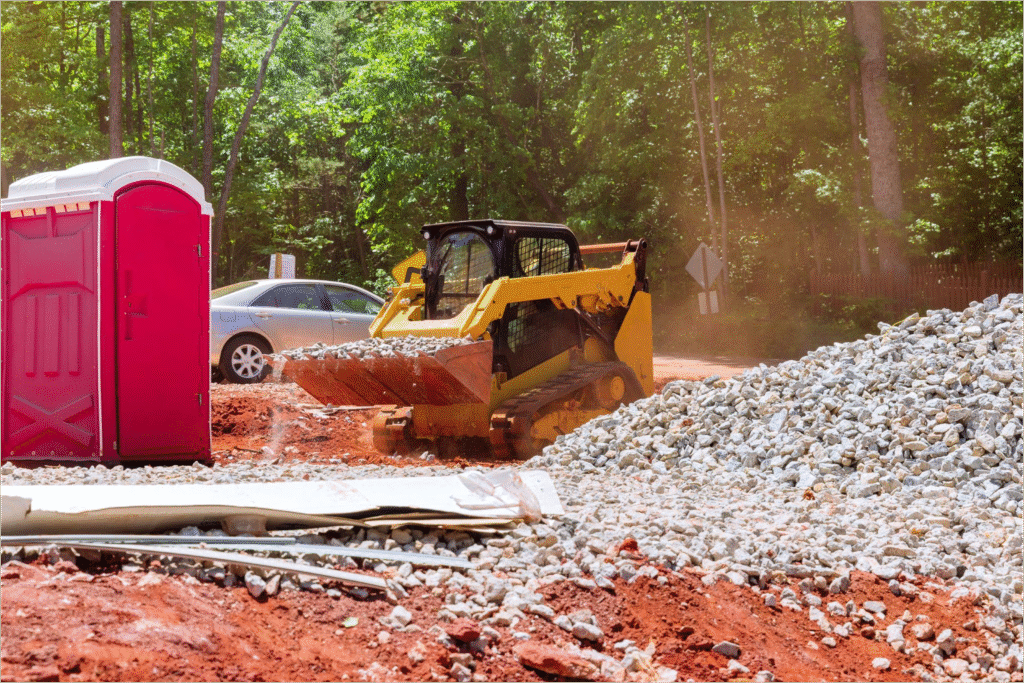

The Reality of Shop Delays on Busy Construction Sites

Every crew knows the feeling of waiting on shop support while machines sit idle. On a construction site, even short delays can snowball into lost hours and tighter deadlines.

It happens often. Multiple crews spread across sites, a concrete pour scheduled after dark, or a grading job that can’t pause.

When one task stalls, it bottlenecks the entire chain of work. That’s why field maintenance teams are starting to lean on extra support. Having a reliable backup plan keeps jobs on schedule and projects moving forward.

Why Field Maintenance Teams Need a Backup Plan

Shops are the backbone of any fleet, but they can’t always be everywhere at once. Crews in the field aren’t looking to replace the shop. They’re looking for a way to fill the gaps when timing gets tight.

Picture a utility crew in the middle of trench work. They can’t just stop for hours waiting on maintenance. A plan that covers those gaps helps prevent setbacks while still leaning on the shop’s expertise.

With the right field-ready support, maintenance becomes a partnership instead of a roadblock.

Mobile Oil Change Service Trucks as the Missing Link

This is where mobile oil change service trucks step in as the bridge between shop support and field needs. These units can take care of essential service work right where the machines are running.

With a mobile setup, crews can:

- Handle PMs like oil, grease, and DEF in the field.

- Stay on schedule by hitting service intervals without waiting.

- Avoid costly hauls back to the shop for routine maintenance.

And because no two job sites are alike, crews can choose setups that fit their reality. It might be a non-CDL truck that anyone on the crew can move. Or a trailer that gives quick coverage across a site. Even a skid tucked into a service vehicle can do the job. Whatever the setup, there’s flexibility to match the work.

Field-Proven Benefits Construction Crews Rely On

Adding mobile lube to the mix isn’t just about convenience. It’s about keeping crews productive and safe. The benefits show up fast when teams use these setups to back up the shop.

- Reduced downtime: Service happens on-site, not hours away.

- Multi-site coverage: One truck can support several crews in a single day.

- Safety & reliability: Smart layouts help prevent spills, fatigue, and missed steps.

- Crew efficiency: Organized bays, durable parts, and proven builds keep the workflow smooth.

These gains add up across shifts and projects. When maintenance feels seamless, crews can stay focused on the job that matters most: building.

Real Jobsite Scenarios Where Mobile Lube Makes the Difference

Every construction crew has seen how small gaps turn into major delays. With mobile lube, those gaps close quickly.

- Grading crews keep trenching projects on schedule without pulling machines off-site.

- Utility teams can keep equipment running during off-hours and unexpected outages.

- Concrete crews finish pours without risking downtime at a critical stage.

These stories aren’t theory—they’re lived experiences across jobsites. And the truth is, we’ve seen it before and helped crews fix it. The right setup can be the difference between a lost day and a finished job.

Choosing the Right Setup for Your Crew

No two crews or sites operate the same way, which is why a one-size-fits-all solution doesn’t work. The best approach is choosing equipment that fits the way your team works.

Options include:

- Full-service lube trucks for heavy coverage.

- Service vans for versatile, compact support.

- Skids that fit into existing pickups or service vehicles.

- Towable trailers for quick mobility across jobsites.

The key is customization: designing around your crew, not the catalog. If your team is juggling sites and shifts, the right build will make the work easier. Let’s find what works for your crew.

Keeping Crews Moving, No Matter Where the Work Is

The shop will always be the backbone of fleet maintenance, but it can’t always be there in the moment. Mobile lube is what bridges that gap, making sure crews don’t lose momentum when the schedule is tight.

Field-ready units help protect uptime, reduce risk, and keep construction projects moving. And the best part? You don’t have to choose one over the other.

Shop support and mobile setups work together. Both give crews a stronger, more reliable way to get the job done.

If you’re weighing field support, find what works for your crew now.