Many industries run on multidimensional control systems, sensors, and robots. These interconnected systems require continuous communication to maximize workflow and efficiency. Communication failure and other delays trigger costly interruptions. Plant operators and owners utilize multiple strategies to minimize interruptions and workflow inefficiencies. The use of industrial switches to automate system integration streamlines remote equipment connections and plant layout expansions.

These switches protect equipment from the dangers of electrical interference, extreme heat, and moisture levels. They are reliable solutions for plants running fully/semi-automated production processes. They are indispensable in situations where commercial switches are unable to handle increasing operational and physical demands.

This article discusses how industrial switches improve operational efficiency.

1. Minimizes Downtimes and Enhances Failover

Interruptions in the manufacturing plant network can originate from communication issues, equipment malfunctions, and power disruptions. These issues can be a failed network link or switch. These translate to real-time data exchange issues between robots, PLCs, and sensors.

Additionally, downtimes can slow or stop the production line. Environmental issues, including electrical interference, increasing temperatures, and vibration. Manufacturing plants running on a single communication path experience delays when faults occur within a single path.

In such a situation, manufacturing plants that have industrial switches installed and functioning experience fewer delays and unstable operations. Advanced switches support failover and redundancy capabilities. The systems can create several paths, ensuring efficient data transmission. Consequently, the systems reroute traffic to an alternative route when the original one fails. The automatic traffic rerouting through dual power inputs can increase production. Surge production prevents issues during electrical overflows.

2. Hardwearing and Ruggedized Construction

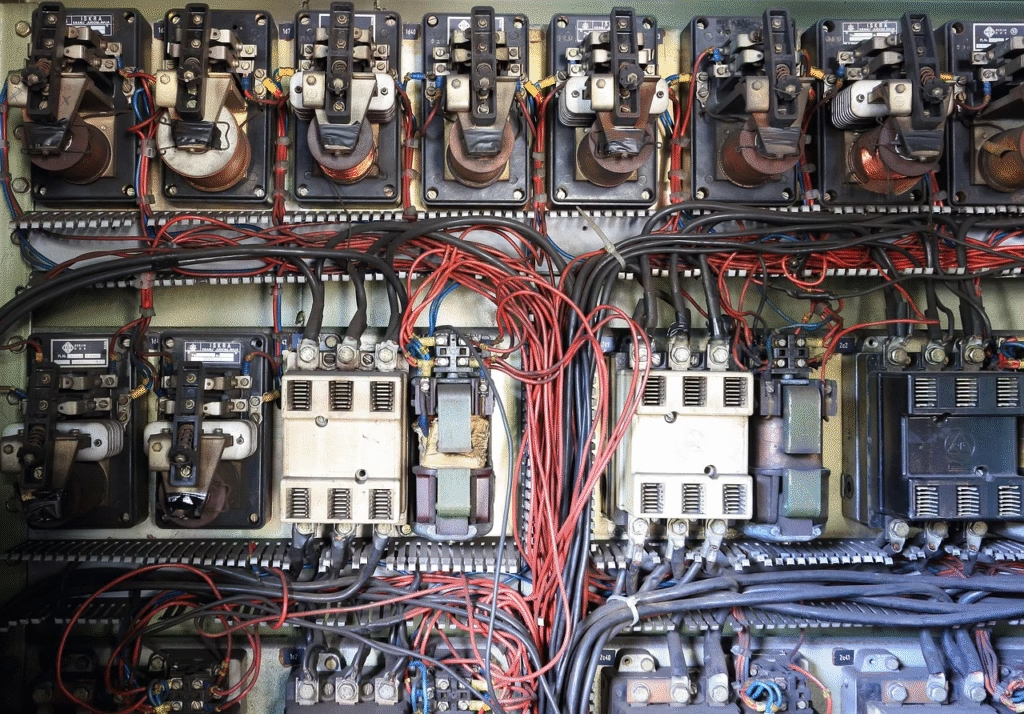

Heavy-duty conveyor systems and machinery in manufacturing plants produce electrical noise and vibration. The areas close to robotic cells, welding stations, and CNC machines have higher electromagnetic and heat levels. Additionally, areas where processing and packaging occur handle higher dust levels, while chemical treatment areas have higher chemical and moisture residues. Storage yards and loading bays encounter humidity and temperature fluctuations.

Industrial switches have ruggedized hardware to ensure reliable operation in harsh conditions. Most use reinforced polymer or metal enclosures to safeguard internal components from humidity and dust. The conformal coatings on electronic components can prevent these switches from chemical and moisture impact. The switches utilize diverse temperatures with heat-dissipating designs to handle extreme heat. Many industrial switches have vibration-resistant connectors, secured board mounting, and robust solder joints.

3. Streamlines Real-Time Data Transmission

Manufacturing plants have supervisory control systems, sensors, programmable logic controllers, and human-machine interfaces. These systems must communicate without disruption to achieve process optimization and synchronization. Industrial switches are the central nervous system of the plant’s communication network. They optimize the delivery of real-time data by routing data packets between devices. Additionally, these switches use Quality of Service features to prioritize time-sensitive traffic. Many manufacturing plants with these systems installed achieve higher failover and redundancy capabilities.

Real-time data transmission can enhance the efficiency of manufacturing processes in many ways. They support instant responses to sensor inputs for regulating assembly lines, robotics, and machine operations. Operators in these plants can optimize machine health by detecting anomalies early. The switches deliver updated data on failures, supporting scheduling maintenance to reduce unplanned downtime. Data collected from quality sensors and vision systems support instant corrective actions.

4. Flexible and Accessible Network Architecture

Manufacturing plants experience substantial growth over time. These organizations record expansions that require new workstations and upgraded solutions. The growth cultivates the need to scale the network while maintaining the design. A key feature of industrial switches is modular network scaling, ensuring engineers can add control devices, machines, and sensors. They are compatible with TCP, Ethernet, and PROFINET communication protocols.

These switches have the capacity to segment traffic and prioritize critical signals. They can maintain higher stability levels despite the increase in connected devices. Their flexible nature allows plant operators to upgrade production lines and adopt the most efficient solutions without disrupting normal operations.

5. Secures Connected Devices

Manufacturing plants require superior network segmentation and access control. They require uninterrupted access to devices when handling critical information. Many advanced industrial switches have MAC filtering, VLANs, and port-based authentication features. These capabilities streamline the authentication of controllers, machines, and sensors to join specific networks. Authorization helps minimize accidental configuration changes and unauthorized device connections. They help optimize the integrity of diverse workflows while keeping systems synced and encrypted to prevent external manipulations and interceptions.

Using advanced switches can help safeguard your plant against cyberattacks. They make that realizable by easing the adoption of remote monitoring and IoT systems. They are excellent at detecting abnormal traffic patterns and blocking malicious data packets. Additionally, these switches integrate with SCADA security systems and firewalls to optimize the security layer. Some advanced models have intrusion detection systems and real-time event logging, enabling engineers to respond to security issues fast.

Wrapping Up

Many systems and machines in manufacturing settings require robust switching technologies. Industrial-grade switches support process control, automation, and real-time monitoring. Many switches employ rugged construction to optimize their heat, dust, and vibration resistance. Using switches is an effective way to optimize production lines and reduce failures. The systems offer low-latency communication, redundancy, and scalable architecture.

Many manufacturing plants leverage smarter and interconnected systems. Switches are part of the robust architecture that ensures reliability and flexibility. They allow companies to adapt and expand while optimizing productivity.