Your Collection Is Ready. But Is Your Factory Slowing You Down?

Your sketches are final. You’ve picked the plating, sourced a stone reference, and maybe even planned your launch for a seasonal drop or retail pitch.

But timing in jewelry isn’t a luxury—it’s leverage. Miss the trend by two weeks, and you miss the demand. Miss it by a month, and you’re restocking something nobody wants.

And here’s the part nobody tells you: most delays don’t come from creativity. They come from production.

Launching fast isn’t about rushing your ideas. It’s about removing friction. And that means working with a jewelry manufacturer who’s built for modern design cycles.

Click here to explore one that supports speed without compromise.

The Top 3 Bottlenecks That Slow Independent Brands

Even if you have great designs and a clear vision, you’re still vulnerable to structural drag—especially if your factory isn’t optimized for fast-moving, small-batch teams.

1. High MOQs That Stall Iteration

You want to test a 3-style capsule drop. But your factory wants 300 units per SKU. That’s not just capital you can’t afford—it’s an innovation killer. High MOQs trap you in single-bet thinking.

2. Sampling That Takes Weeks (or Longer)

Every time you request a change, you wait. Every design change is a restart. And when CAD and modeling are outsourced, you’re left in a constant loop of delay and blind revisions.

3. No Feedback Until It’s Too Late

Most manufacturers follow your file. But few question it. Will the hinge last? Is the clasp spec reliable? Will this shape cast cleanly at small scale? If you’re the only one catching flaws, you’re not just the designer—you’re also the last line of QA.

What Sets a Speed-Ready Manufacturer Apart

It’s not just about promises—it’s about production design. Factories that support launch momentum don’t just say “yes.” They bake speed into structure:

Low MOQs

Starting as low as 30–50 pieces lets you test without overextending.

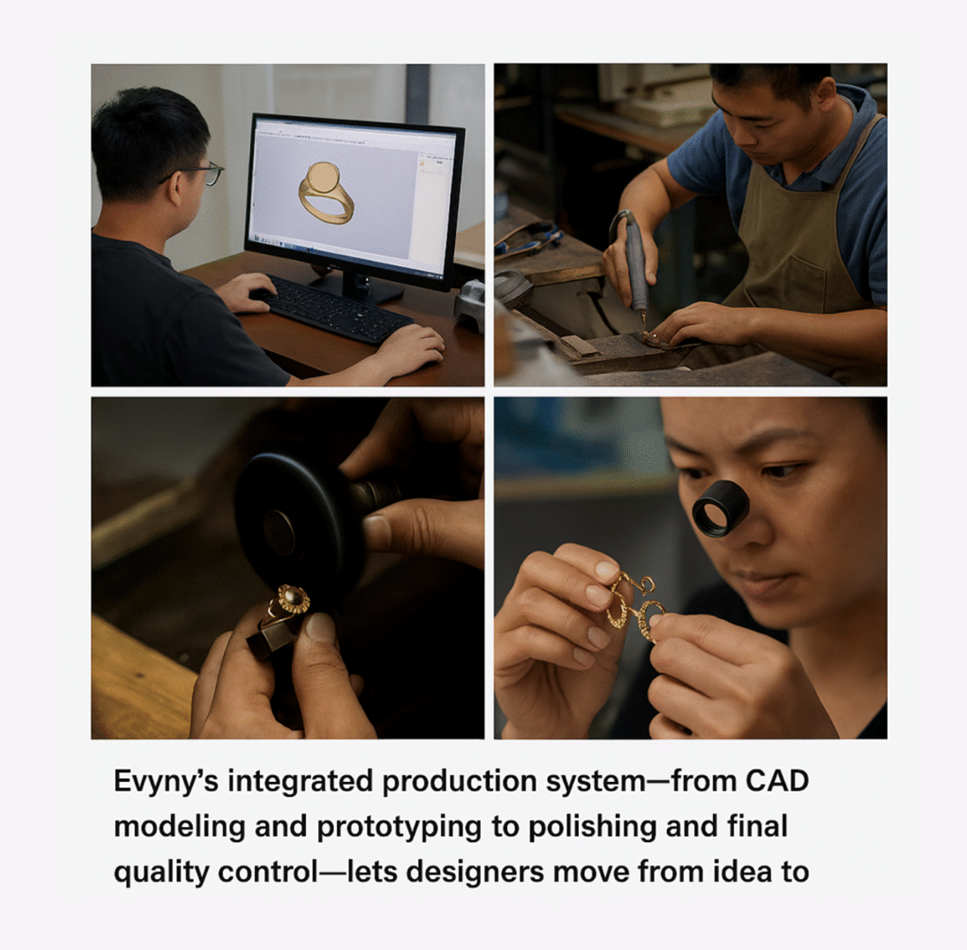

In-House CAD + Modeling

Designs move faster when engineers and stylists sit under the same roof. 3D renderings arrive in days, not weeks. Revisions are real-time, not backlogged.

Proactive OEM Guidance

A collaborative team doesn’t just produce—they advise. They tell you if a piece needs structural reinforcement or if a style is hard to plate. Their input prevents expensive surprises.

Want to see how a full-service jewelry factory in Guangdong, China—with over 150 skilled craftsmen and more than 2,000 square meters of space—handles CAD, sampling, and small-batch production in one place? Check out here to explore an OEM partner designed for modern creative workflows.

What a 30-Day Launch Timeline Actually Looks Like

When your partner’s structure matches your creative rhythm, here’s how a launch can unfold:

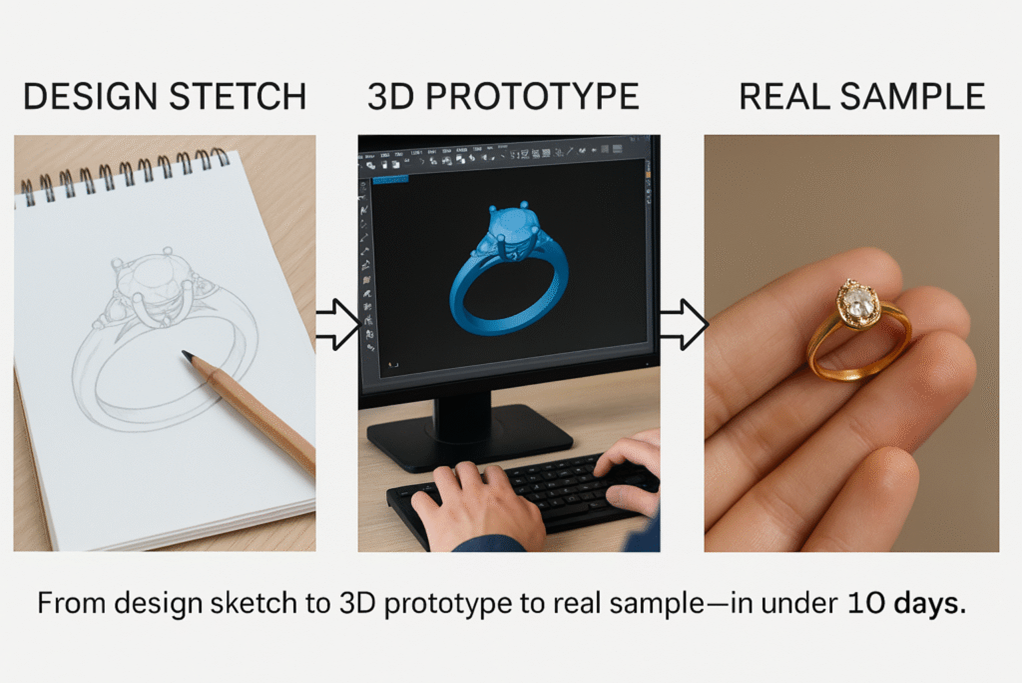

Week 1: Design Finalization + CAD Modeling

You send sketches or moodboards. The in-house CAD team delivers production-ready 3D models in just days.

Week 2: Sampling + Revisions

Samples arrive in 7–10 days. Small tweaks—plating finish, clasp type, proportions—are adjusted without stalling the process.

Week 3: Batch Production

Approved designs move straight to small-batch execution (often just 50–100 pcs). No lost time.

Week 4: Pack + Launch

Products are QC’d and ready. Optional add-ons like commercial photography give you assets to launch immediately.

This timeline isn’t just a marketing pitch. It’s what happens when your manufacturer is built to support momentum—not block it.

Bonus: Who Benefits Most From This Speed?

This isn’t just for hypergrowth DTC brands. If you’re:

- Testing product-market fit with a new collection

- Launching a side line outside your main retail channel

- Moving into wholesale or subscription box formats

…then speed lets you validate faster and reinvest smarter.

It also benefits designers launching collections tied to cultural or seasonal moments—like Lunar New Year, wedding season, or fashion week pop-ups—where missing the moment means missing the margin. A responsive manufacturer lets you align production with your calendar, not theirs. And when timing syncs with relevance, every SKU works harder.

…then speed lets you validate faster and reinvest smarter.

Manufacturer Vetting Checklist (Save This)

| Capability | Why It Matters |

| MOQ ≤ 50 units | Let’s you launch lean and diversify designs |

| 7–10 Day Sampling | Keeps you inside trend and season windows |

| In-House CAD + 3D Services | Prevents delays and misalignment |

| OEM Feedback on Designs | Saves time and cost through better decisions |

| Clear Timeline and Communication | So you know what’s next—without guessing |

Pro Tip: Ask each factory how they deliver these. If they can’t answer in detail, keep looking.

Real Example: From First Collection to Retail-Ready

One designer we supported had just left a large retail brand to launch her own line. Her goal? A 3-piece capsule collection on Instagram to validate customer demand.

Working with Evyny, she submitted hand sketches and reference notes. Our CAD team returned polished 3D files in four days. After sample approval, her first 45-unit batch was finished in under 3 weeks. She sold out in 6 days.

Based on early feedback, her second run included a tighter clasp and alternate plating. By month three, her brand was stocked in 3 concept boutiques.

This is what a fast, flexible partnership makes possible—even for new designers without big budgets.

Final Thought: Speed Isn’t Optional. It’s Competitive Edge

In fast-moving industries like fashion and accessories, being first to market isn’t a brag—it’s a moat. Consumers respond to what’s new, and trends can flip in weeks. A slow supply chain doesn’t just delay your launch—it erodes your edge before you ever go live.

If your launch is slow, the problem isn’t your idea. It’s your infrastructure.

Speed matters—not because fast is trendy, but because the market moves. Your audience moves. And if your manufacturer can’t move with you, you fall behind.

The right jewelry factory doesn’t just deliver product. It removes delays, flags risks, and adapts to how you launch.

You’ve built a design worth releasing. Now make sure your production system is ready to keep up.