In modern manufacturing, metal stampings aim to increase efficiency and productivity across various sectors. This process creates metal parts by shaping, cutting, or forming metal sheets using precision machinery. Its widespread application in industries like automotive, aerospace, electronics, and even construction is driven by the need for cost-effective production and consistent quality.

As companies strive to optimize their operations, metal stampings offer a solution that combines flexibility, precision, and scalability. Let’s dive deeper into the benefits of metal stampings and explore how they encourage efficiency in numerous applications.

What to Know About Metal Stampings

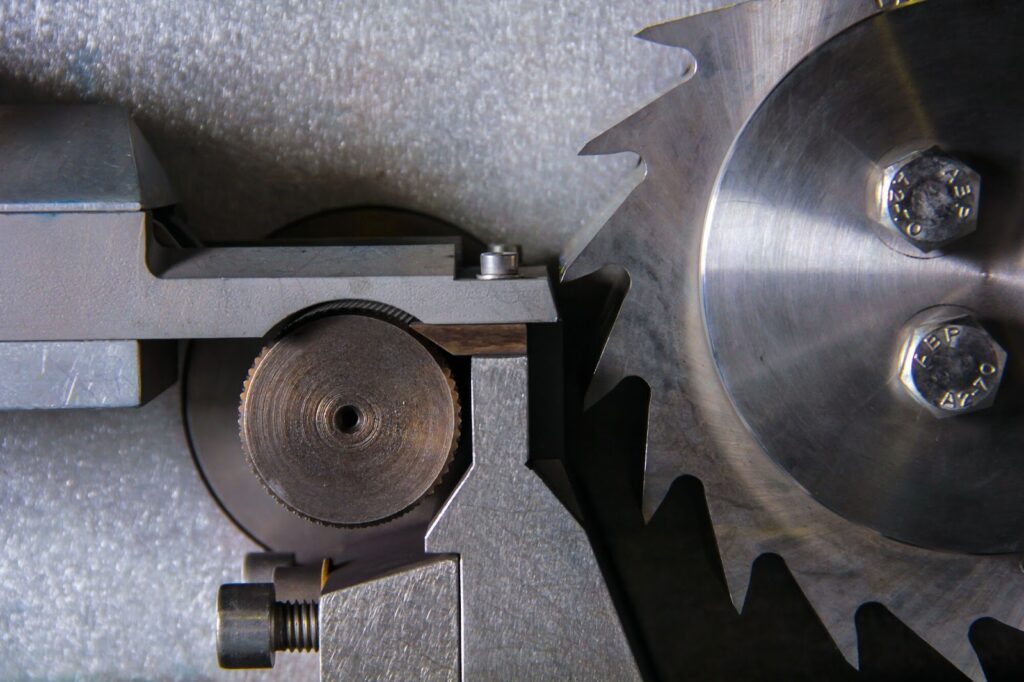

Metal stampings are produced through various methods, primarily involving die cutting, bending, and punching processes. The metal sheet, made from steel, aluminum, or copper, is fed into a stamping press where it undergoes a series of operations. These techniques allow for intricate designs and high-volume production and maintain tight tolerances.

The precision achieved in metal stampings leads to reduced waste and improved sustainability for modern manufacturers. Metal stampings streamline production and contribute to the integrity of the final product. By sourcing components from reliable suppliers like Elyria Spring & Stamping, businesses are receiving high-quality parts that meet industry standards. This reliability will make the manufacturing process more efficient and cost-effective.

Benefits in the Automotive Industry

The automotive industry has embraced metal stampings for body panels, brackets, and fasteners. One of the primary benefits is the ability to produce lightweight parts without sacrificing strength. Metal stampings offer superior strength-to-weight ratios, ideal for creating structural components that withstand high levels of stress.

Advanced stamping techniques allow for complex shapes and designs, enabling more aerodynamic vehicle profiles. The efficiency of mass production with metal stampings reduces labor costs and speeds up time-to-market for new vehicle models. The consistent quality of stamped parts translates into improved safety and performance in automobiles.

The Aerospace Sector’s Dependence on Precision

In aerospace manufacturing, precision and reliability are non-negotiable standards. Metal stampings produce aircraft parts, where any deviation in quality could have catastrophic consequences. Aircraft components must meet rigorous safety regulations and performance criteria, which are achieved through precision stamping techniques.

The rapid prototyping capabilities of modern stamping technologies allow aerospace manufacturers to test designs and iterate quickly, leading to faster development cycles. Thanks to their capability of handling complex geometries and material types, metal stampings can easily maintain the high standards required in aerospace manufacturing.

Electronics and the Demand for Accuracy

The electronics industry heavily relies on metal stampings for housings, connectors, and heat sinks. Even minor discrepancies can render electronic products ineffective. Metal stampings provide the precision necessary to create components that fit together seamlessly for optimal performance. They produce intricate designs to meet consumer demand for compact devices.

Some techniques (progressive stamping, to mention the most common one) enable manufacturers to create multiple parts simultaneously.

High-frequency and low-loss materials in metal stampings contribute to better energy efficiency in electronic devices. The demand for innovative stamping solutions rises, underscoring the importance of staying ahead in the market.

Construction Industry Advantages

The construction sector benefits from metal stampings in various applications, from structural support to aesthetic elements. Stamped metal parts are employed in building frameworks, HVAC systems, and fixtures, offering durability and stability. Metal stampings reduce the need for welding and assembly, allowing for quicker installation and fewer labor costs on-site.

Stamped components need to suit specific design requirements and maintain structural integrity. Sustainability becomes a priority in new constructions, and metal stampings contribute to eco-friendly practices by promoting recyclability and minimizing waste. Investing in metal stampings offers advantages by improving both efficiency and sustainability within the construction industry.

Metal Stampings in Medical Equipment Manufacturing

The medical equipment sector relies heavily on metal stampings for producing components that must adhere to strict regulatory standards. All components used for medical purposes must meet exact specifications and deliver high durability and consistency. Small, intricate parts help manufacturers create advanced medical technologies that can save lives and improve patient outcomes.

Metal stampings improve production efficiency and can be adapted for both high-mix and low-volume manufacturing, catering to diverse needs in the medical field. This flexibility reduces lead times and mitigates supply chain risks, making it easier to respond to sudden surges in demand. In the healthcare industry, the adaptability and precision of metal stampings will remain central in advancing medical innovations.

Metal stampings stand out as a transformative process across various industries, boosting efficiency, precision, and sustainability. Their applications in automotive, aerospace, electronics, construction, and medical fields demonstrate the versatile benefits they provide.

Leveraging advanced techniques for production, manufacturers can reduce costs and improve lead times while meeting the highest quality standards. These industries are facing new challenges, and metal stampings are poised to shape the future of manufacturing.