When it comes to construction, custom metalwork, or any project that demands precision, choosing the right aluminum fabrication company can make or break the results. Aluminum is a versatile material—strong, lightweight, and resistant to corrosion—but the final quality depends heavily on the skills and practices of the people shaping it.

If you’re a homeowner, contractor, or business owner in San Diego County, chances are you’ve already seen aluminum used in railings, gates, awnings, signage, and structural parts. The tricky part isn’t finding someone who offers fabrication—it’s finding the right partner who understands your vision, stays within budget, and delivers lasting quality.

This guide will walk you step by step through what to look for, the questions to ask, and the red flags to avoid when selecting a fabrication company.

Why Choosing the Right Aluminum Fabrication Company Matters

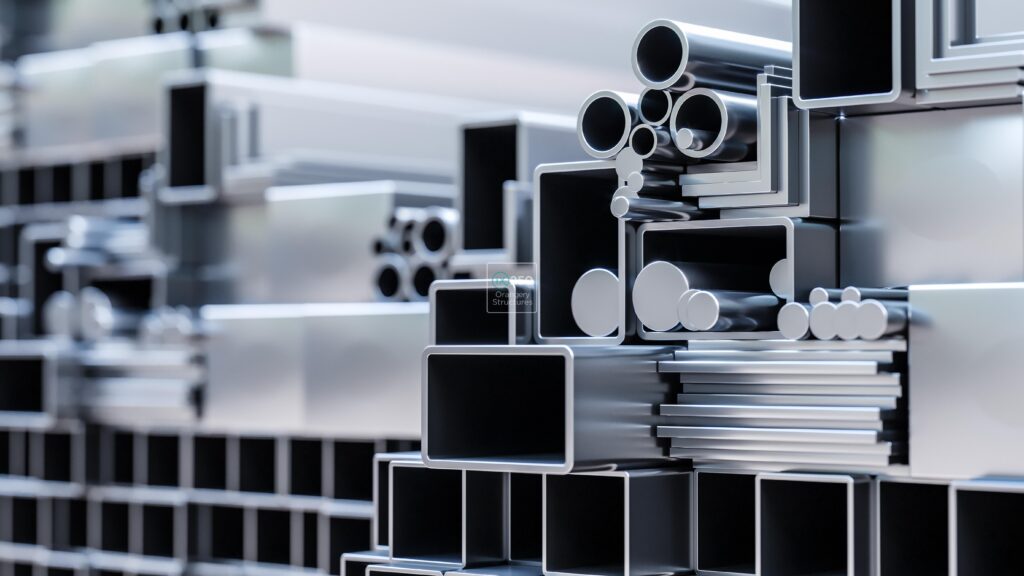

Aluminum isn’t like wood or plastic—you can’t just cut and nail it together. It requires specialized tools, welding techniques, bending machines, and an experienced eye to ensure strength and finish. A poorly fabricated aluminum structure may warp, rust at welded joints, or fail under pressure. That’s why the right aluminum fabrication company matters: they bring both technical knowledge and craftsmanship to the table.

When you’re investing in something like storefront framing, architectural details, outdoor structures, or even simple gates, you need assurance that the work will last. Beyond durability, good fabricators also care about aesthetics. Smooth welds, clean edges, and consistent finishes separate professionals from amateurs.

Qualities to Look for in a Fabrication Company

When narrowing down your options, focus on these key qualities:

1. Experience in Aluminum-Specific Work

Not all metal fabricators are equal. Some specialize in steel, others in stainless, and a few handle aluminum. Aluminum requires different welding and finishing techniques. Ask how many aluminum projects they complete per year and if they have certified aluminum welders.

2. Custom Design Capabilities

Your project may not fit a one-size-fits-all template. A skilled shop should offer custom drawings, design consultations, and mockups. This shows they’re ready to adapt to your unique requirements.

3. Advanced Equipment and Tools

Look for a company with modern CNC machines, bending brakes, and TIG welding stations. Having the right equipment ensures precision and consistency, especially on larger or more intricate jobs.

4. Strong Local Reputation

In a place like San Diego County, word travels fast. Check online reviews, testimonials, and even local trade associations. Companies that consistently deliver quality will have a track record you can verify.

5. Range of Services Offered

Some companies only cut and weld, while others handle the full process—design, fabrication, finishing, and installation. The more comprehensive their service, the smoother your project will run. Many customers in the area specifically look for aluminum fabrication services San Diego County that handle projects from start to finish without outsourcing.

Steps to Choosing the Right Aluminum Fabrication Company

Once you understand what qualities matter, follow these steps to make a confident choice:

Step 1: Define Your Project Clearly

Before approaching any fabricator, know what you need. Write down the purpose, size, style, and any functional requirements. For example:

- A decorative aluminum gate with modern lines

- A lightweight canopy frame

- Durable storefront framing for a retail shop

Clear goals help the fabricator give accurate estimates and avoid misunderstandings.

Step 2: Research Local Providers

Search online, ask for referrals, or drive around to spot signage of fabrication shops. Narrow down your list to companies that advertise aluminum work specifically. Keep an eye out for those offering san diego fabrication services, as they usually understand local codes, permits, and climate-related challenges better.

Step 3: Review Portfolios and Past Work

Most reputable companies maintain a gallery of past projects. Study these carefully. Look for consistency, creativity, and quality finishes. If the company doesn’t display past work, ask for references.

Step 4: Check Certifications and Training

Ask whether the company’s welders are certified in aluminum. Many fabricators will have AWS (American Welding Society) certifications that demonstrate proficiency.

Step 5: Request Multiple Quotes

Don’t settle for the first price you’re given. Request at least three quotes to compare. Pay attention not just to cost, but to timelines, included services, and warranties.

Step 6: Visit the Workshop

A visit can reveal a lot. Is the shop organized, with proper safety measures? Are the machines well-maintained? A clean, efficient workshop is usually a sign of professionalism.

Step 7: Ask About Lead Times

Some shops may be booked for months, while others can start immediately. Ask how long your project will take and get a written timeline.

Step 8: Look for Transparent Communication

The right company will take the time to answer your questions, explain processes, and break down costs. Vague answers or pushy sales tactics are red flags.

Questions to Ask Before Hiring

Here are some direct questions that can help you evaluate potential partners:

- Do you specialize in aluminum, or do you primarily work with other metals?

- Can I see a portfolio of projects similar to mine?

- Who will handle design, cutting, welding, and finishing—do you outsource any steps?

- What warranties or guarantees do you offer on workmanship?

- Are your welders certified for aluminum welding?

- Do you provide installation as part of your aluminum fabrication services in San Diego County?

- Can you provide references from past clients?

Red Flags to Watch Out For

Even if a company looks good on paper, stay cautious if you notice:

- Extremely low bids compared to others (often means shortcuts)

- Unwillingness to provide references or past work examples

- Vague answers about timelines or costs

- Dirty or poorly maintained shops

- Pushy sales tactics without listening to your needs

The Role of Local Expertise

Hiring locally isn’t just convenient—it’s practical. A company offering San Diego fabrication services knows the climate challenges (like salt air near the coast), understands local architectural trends, and is familiar with city codes and permits.

For example, coastal neighborhoods like La Jolla or Coronado may require extra corrosion resistance in aluminum railings and gates. A local expert will already account for these conditions without you needing to ask.

Cost Factors to Consider

While price should never be the only factor, understanding what goes into a quote can help you budget wisely. Typical costs include:

- Raw aluminum materials

- Cutting and shaping labor

- Welding and assembly

- Finishing (powder coating, painting, polishing)

- Installation fees

- Permit or inspection costs if required

Cheaper doesn’t always mean better. Quality aluminum fabrication, especially for structural or architectural use, is worth the investment.

Also Read: Why Are Large Format Surfaces Trending in Interior Design?

Benefits of Choosing the Right Company

When you take the time to choose carefully, you gain:

- Durability: Well-crafted aluminum will last for decades with minimal maintenance.

- Safety: Proper welds and joints prevent failures under stress.

- Aesthetics: Smooth finishes and accurate designs improve property value.

- Peace of Mind: Working with professionals reduces stress and project delays.

Common Applications of Aluminum Fabrication

If you’re wondering where aluminum fabrication applies in everyday San Diego County homes and businesses, here are examples:

- Gates and fencing

- Patio covers and pergolas

- Storefront frames and windows

- Railings and staircases

- Custom signage

- Industrial frames and parts

Final Thoughts

Choosing the right aluminum fabrication company is about more than just finding someone with the right tools. It’s about experience, communication, and local expertise. A company that takes pride in its work, offers clear answers, and has a proven track record will deliver results that last.

In San Diego County, the demand for aluminum fabrication services is strong, and homeowners or businesses who carefully vet providers end up with structures that look great and hold up against the region’s sun, salt air, and wind. Whether you need a small custom job or a large-scale installation, working with skilled professionals in san diego fabrication services will ensure your project is done right the first time.

FAQs

1. How do I know if a company is the right aluminum fabrication company for my project?

Look for a track record of aluminum-specific projects, certifications in aluminum welding, and a portfolio that shows consistent quality. Also, ask for references and confirm they can meet your project’s timeline.

2. What services are usually included in aluminum fabrication?

Most companies handle cutting, welding, bending, and assembly. Some also offer finishing services such as powder coating or polishing, and full installation. In San Diego, many shops that provide aluminum fabrication services San Diego County cover everything from design to installation.

3. Why should I choose local san diego fabrication services instead of going outside the area?

Local providers understand San Diego’s building codes, climate factors (like coastal corrosion), and design trends. This ensures your project not only looks good but also holds up in local conditions.

4. How long does aluminum fabrication usually take?

Timelines vary depending on the size and complexity of the project. Small items may take a week or two, while large custom structures can take several months. Always ask for a written schedule before work begins.

5. Is aluminum more expensive than other metals for fabrication?

Aluminum can be more affordable than stainless steel and is often cheaper to transport due to its lighter weight. While the upfront material cost may be slightly higher than mild steel, its durability and resistance to rust usually make it a cost-effective choice over time.