Humanoid robots

Humanoid robots and their bipedal design have become increasingly helpful in various fields. Their resemblance to humans makes them more useful in extensive applications, allowing them to handle many tasks that may even be difficult for humans.

But what is a humanoid robot, and how does its design allow it to perform its various functions? This article will answer these questions and many more. You will also learn the materials and manufacturing processes used to create these robots. Let’s get into it!

What Is A Humanoid Robot?

A humanoid robot is a type of robot designed to resemble and imitate human characteristics and behaviors. This includes physical features such as a head, torso, arms, legs, and hands, as well as the ability to move and interact in a human-like manner. This enables them to perform tasks similar to humans, such as walking, talking, grasping objects, and navigating environments.

Humanoid robots performing different functions

The design of a humanoid robot often involves advanced engineering and technology. The robot’s physical structure is typically made from materials like metal, plastic, and composites, which are lightweight yet durable. The joints and actuators of the robot allow for smooth and precise movements, mimicking the flexibility and range of motion of human limbs.

One of the key features of humanoid robots is their ability to communicate with humans using various modalities. This communication can be through spoken language, gestures, facial expressions, or graphical interfaces. By understanding and responding to human commands and cues, humanoid robots can collaborate with people in diverse settings such as homes, hospitals, factories, and public spaces.

How Does a Humanoid Robot Work?

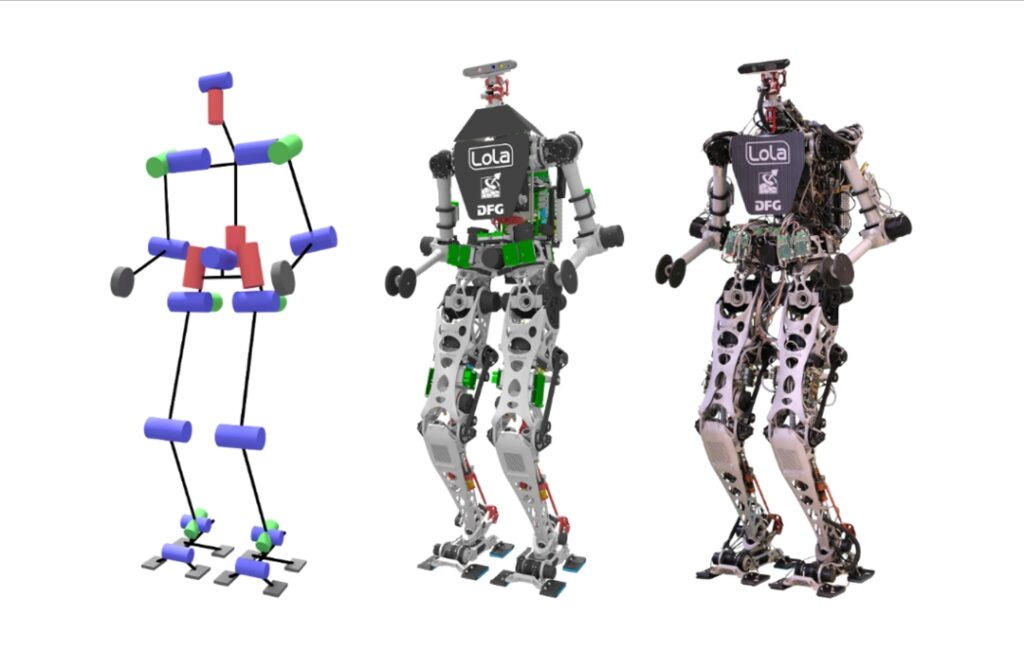

A humanoid robot works by integrating mechanical, electrical, and software systems to emulate human movements and behaviors. It has a physical structure comprising various components such as joints, actuators, sensors, and a body frame. These components work together to give the robot mobility and dexterity, allowing it to move its arms, legs, head, and other body parts.

How a humanoid robot works

The joints in a humanoid robot are typically designed to mimic human joints, such as shoulder joints, elbow joints, hip joints, and knee joints. These joints are connected to actuators, which are devices that control movement. Actuators can be electric motors, hydraulic cylinders, or pneumatic actuators, depending on the design of the robot.

Sensors play a crucial role in how these robots work. These sensors gather information from the robot’s environment. The information may include visual data from cameras, spatial awareness from depth sensors, touch feedback from tactile sensors, etc. The robot’s control system processes this sensory input to make decisions and adjust its movements.

The control system of a humanoid robot consists of hardware and software components that govern its behavior. The software includes algorithms for motion planning, navigation, object recognition, and interaction with humans or objects. These algorithms enable the robot to perform tasks like walking, grasping objects, avoiding obstacles, and responding to commands.

Communication is another essential aspect of how a humanoid robot works. It can communicate with humans or other machines through speech, gestures, or interfaces such as touchscreens or buttons. This communication facilitates collaboration and coordination in various applications, from assisting with household chores to working in industrial settings.

Structure of Humanoid Robot

Humanoid robots possess a complex internal structure that allows them to move and interact with the world. Their motion relies on a careful interplay between several key components:

Structure of a humanoid robot

Server System

This central computing and processing unit is responsible for controlling and coordinating the robot’s movements, actions, and responses. This system typically consists of high-performance processors, memory modules, and input/output interfaces. The server system performs the following actions:

- processes sensory data from the robot’s sensors

- executes control algorithms for motion planning and navigation

- manages communication with external devices or networks.

It plays a crucial role in ensuring the smooth and efficient operation of the humanoid robot.

Reducer: Wave Reducer vs. RV Reducer

Reducers are mechanical components used in humanoid robots to reduce motor rotation speed and increase torque output for precise and powerful movements. Two common types of reducers used in these robots are wave reducers and RV (harmonic drive) reducers. Wave reducers use flexible components to achieve gear reduction, resulting in compact size and high precision. On the other hand, RV reducers use a unique toothed design to achieve high torque transmission with minimal backlash and smooth operation.

The choice between these reducers depends on application requirements, space constraints, torque demands, cost considerations, etc. Wave reducers might be preferred for tasks requiring high speed and agility. Conversely, RV reducers could be the better option for applications demanding exceptional precision and stability.

Control System

The control system of these robots encompasses hardware and software components that govern their behavior and functionality. This system includes sensors for perception, actuators for movement, and a central processing unit for decision-making and coordination. The control software includes algorithms for motion control, balance control, task execution, and human-robot interaction. Advanced control systems may also incorporate machine learning and adaptive control techniques. This helps improve performance and adaptability in different environments and tasks.

Coreless Motor

These are lightweight and efficient electric motors commonly used in humanoid robots for powering various joints and actuators. These motors feature a coil-wound rotor without an iron core, which reduces inertia and improves responsiveness. These motors offer high power-to-weight ratios, low cogging torque, and smooth operation. Thus, they are suitable for applications requiring precise and dynamic movements, such as walking, grasping, and manipulation tasks in humanoid robots.

AI Machine Vision System

This is the integration of artificial intelligence (AI) algorithms and computer vision techniques for visual perception and recognition tasks. This system includes cameras, image sensors, and processing units that capture and analyze visual data from the robot’s surroundings. AI algorithms enable the robot to recognize objects, people, gestures, and environments. This facilitates navigation, object manipulation, and human-robot interaction. The machine vision system enhances the robot’s autonomy, adaptability, and situational awareness. Thus, it can perform complex tasks with precision and efficiency.

Different Materials for Humanoid Robot

The remarkable capabilities of humanoid robots rely on advanced technology and the materials chosen for their construction. Here’s a breakdown of some commonly used materials in these robots:

Material for machining humanoid robot components

Copper

This versatile metal offers excellent electrical conductivity, making it suitable for the robot’s wiring, electrical contacts, and circuitry. Copper’s malleability and ductility allow for easy shaping and forming into complex parts. These parts may include connectors and conductive traces on circuit boards. Additionally, copper has good thermal conductivity. Thus, it helps dissipate heat generated by electronic components in the robot’s systems.

Brass

Brass possesses properties such as corrosion resistance, machinability, and aesthetic appeal. Brass components in humanoid robots may include fittings, fasteners, decorative elements, or parts requiring a balance of strength and workability. Its antimicrobial properties also make it suitable for applications where hygiene is important. Examples include healthcare robots or human-robot interaction scenarios.

Aluminum

This lightweight and corrosion-resistant metal is a great choice for structural components, frames, and housings in humanoid robots. Its low density makes it ideal for reducing robot weight without compromising strength or durability. Aluminum parts in these robots can include chassis, arms, legs, and panels. It is highly machinable and easily anodized for added protection and aesthetics. This further enhances its suitability for robotic applications.

Stainless Steel

Stainless steel is valued in humanoid robot construction for its strength, corrosion resistance, and hygienic properties. It is commonly used for joints, actuators, brackets, and components exposed to harsh environments or requiring high mechanical strength. Stainless steel alloys offer hardness, toughness, and resistance to wear and tear. Therefore, they are suitable for critical robot components that undergo repeated stress and motion.

Magnesium Alloys

These lightweight yet strong materials reduce overall weight and enhance mobility and energy efficiency in humanoid robots. These alloys exhibit good strength-to-weight ratios, thermal conductivity, and electromagnetic shielding properties. Components made from magnesium alloy in these robots may include frames and brackets. They are also useful for parts requiring a balance of structural integrity and lightness for mobile or agile robots.

Manufacturing Techniques for Custom Humanoid Robot Components

Building a custom humanoid robot requires advanced manufacturing techniques to create its unique components. Here’s a closer look at some prevalent techniques used in humanoid robot component manufacturing:

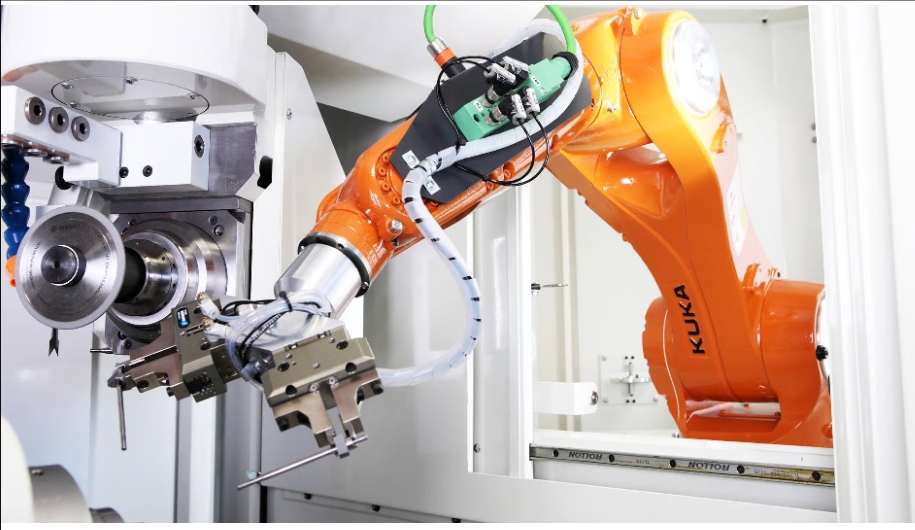

Manufacturing processes for humanoid robots

5-axis CNC Machining

For components requiring intricate shapes and high precision, 5-axis CNC machining reigns supreme. This computer-controlled process utilizes a rotating tool that carves away material from a solid block, meticulously sculpting it into the desired shape. The 5-axis capability allows the tool to reach complex angles, enabling the creation of intricate robot parts like joints, gears, and even customized grippers for manipulating objects. For instance, a 5-axis CNC machine could be used to manufacture a robot hand with individual, precisely articulated fingers.

Sheet Metal Fabrication

This cost-effective technique is ideal for creating a humanoid robot’s lightweight yet sturdy structural components. Thin metal sheets, such as aluminum or steel, are cut, bent, and shaped using tools like presses, brakes, and lasers. This method allows for the rapid production of robot parts like the torso, limbs, and protective casing. For example, sheet metal could be used to fabricate the leg segments of a walking humanoid robot.

Casting

Metal Casting offers a time-saving and cost-effective solution for mass-producing specific robot components with complex shapes. Molten metal is poured into a mold designed with the desired component’s shape. Once cooled and solidified, the metal takes the form of the mold, creating a replica. Casting is suitable for parts requiring intricate internal structures, such as robotic hands or gear housings. For instance, a humanoid robot’s hand with intricate internal mechanisms for finger movement could be cast using this technique.

3D Printing

3D printing, also known as additive manufacturing, revolutionizes the creation of custom humanoid robot components. This technique builds objects layer-by-layer from a digital blueprint. Its versatility allows for creating complex shapes with intricate internal features that might be difficult or impossible to achieve with traditional methods. Additionally, 3D printing facilitates rapid prototyping, allowing engineers to test and refine designs quickly. For example, 3D printing could be used to create a customized robotic arm with unique gripping mechanisms or sensors embedded within its structure.

Conclusion

Humanoid robots represent a significant technological advancement. Their resemblance and interactions with us open vast possibilities across various industries. As research and development continue, we can expect these robots to become even more sophisticated and capable.

Advancements in artificial intelligence, material science, and manufacturing techniques will further enhance their dexterity, intelligence, and adaptability. This paves the way for a future where humanoid robots seamlessly integrate into our society, working alongside us and improving our quality of life.