Metal stamping design

Did you know that up to 50% of manufacturing time can be lost in correcting design errors? The cost effect on the manufacturing process can be dire, so insisting on proper metal stamping design is crucial.

Design is always the first step in any metal stamping project, and focuses on critical specifications such as dimensions and tolerances. Therefore, dependable metal stamping design should account for material properties, tooling geometry, forming forces, and material flow.

The purpose of this article is to outline the fundamental standards and considerations for the metal stamping design process.

What is Metal Stamping Design?

Metal stamping is the procedural, technical planning of the steps and approach for metal stamping, which transforms sheet metal into usable parts through die operations.

The sheet metal design step outlines the critical elements of the process, including tooling requirements, material properties, part geometry, metal stamping die design, and stamping procedure. The specifications are important because they ensure process repeatability, high-quality parts, and cost optimization.

Metal Stamping Design for Bending

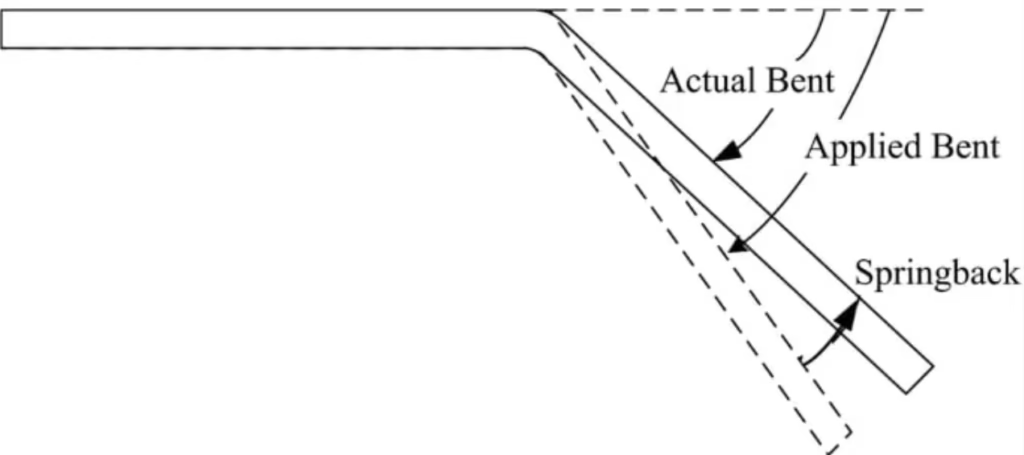

Bending operations in metal stamping require careful attention to bend-to-holes distances, bend radius, sheet material properties, and springback.

Springback

At ProleanTech, these are some metal stamping design guidelines to achieve accurate parts while preventing cracking and failure.

Therefore, the following specific metal stamping design requirements should be checked.

Bends Near Holes

A bend should not be too close to a hole to prevent hole deformation. A distance equivalent to 2x the material thickness should be left for holes up to 2.5mm in diameter or width, plus the form radius.

If a hole is larger than 2.5mm in diameter or width, the allowance is increased to 2.5x the material thickness plus the form radius.

These standards ensure that the hole does not distort, bulge, or stretch against the set tolerances. Otherwise, the affected holes may need to be redrilled to size, a process that can be too expensive.

Corners

For corners in a blank used in stamping, the recommended radius is at least 0.5 times the material thickness.

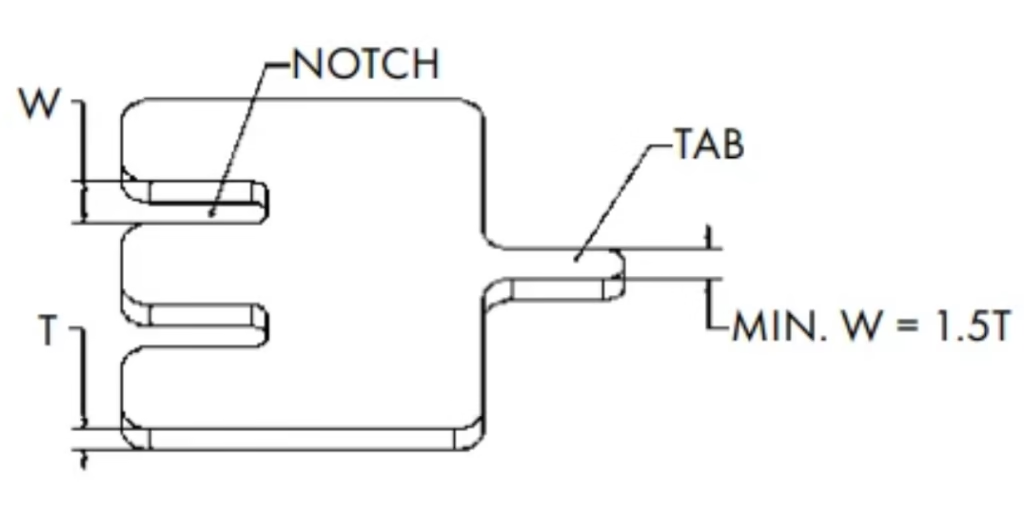

Notches

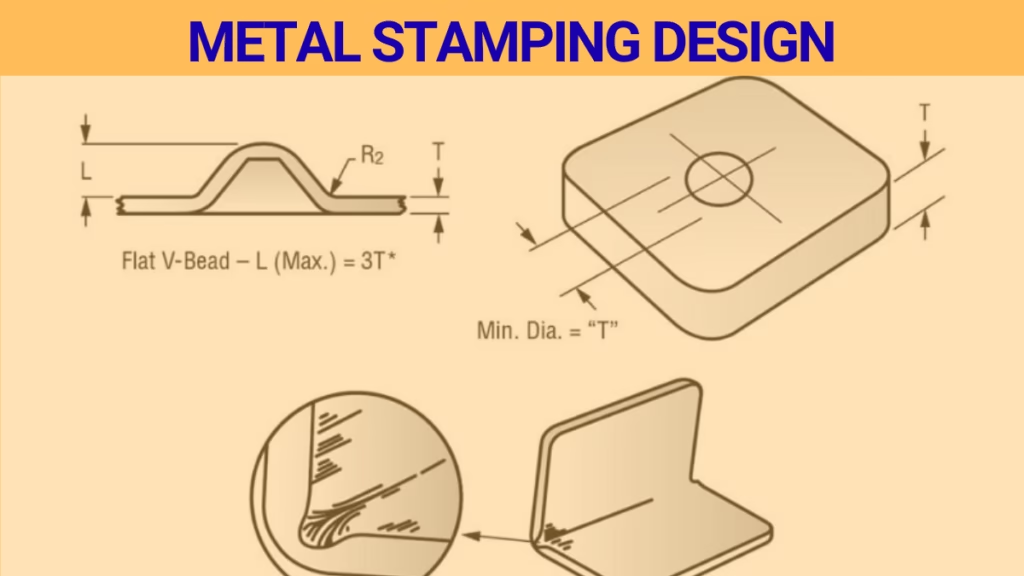

The width of a notch should be at least 1.5x the material’s thickness. Widths smaller than this are challenging to make due to the punch force, which can even break the tool.

Notch and tab design

Burrs

The standard burr allowance in metal stamping design is 10% of the material thickness. To minimize serious burr instances, the designer should avoid complex designs and sharp corners. Considering the burr direction is also critical in metal stamping and forming designs.

Metal Stamping Design for Blanking

Blanking design for metal stamping is another crucial area, whereby aspects such as shear angles and punch-to-die clearances are considered.

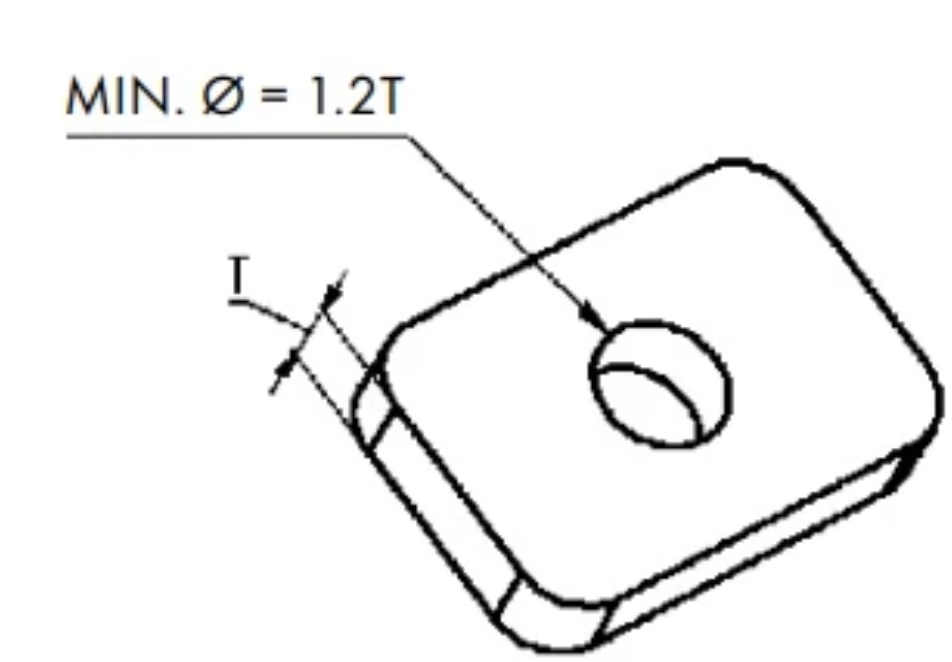

Hole Diameter

Hole diameter

The hole diameter should be at least 1.2 times the material thickness for most materials. For stamped steel sheet and other high-tensile strength materials, the hole diameter should be at least 2 times the material thickness.

The problem with smaller holes is the formation of burrs, even when the manufacturer uses specialized tooling.

Hole Taper

Unlike a machined hole, a stamped hole has a varying diameter from one end of the sheet metal to the other – what’s called taper. To achieve a uniform diameter hole, machining may be required as a secondary operation.

Edge-To-Hole Distance

The recommended distance is 2 times the material’s thickness. Following this guideline prevents bulging in blanking operations. If it is impossible to meet this requirement, specialized drilling is required.

Metal Stamping Design for Coining

No stamping operation surpasses coining in press tonnage requirements. The deformation must be precise, and its design must consider depth, corner radii, material properties, and draft angles.

Grain Direction and Plasticity

Brass, copper, aluminum, and other highly plastic materials form flawlessly. The designer does not have to worry about the grain direction. The minimum bend height requirement for these materials is low, about 20% of stronger materials.

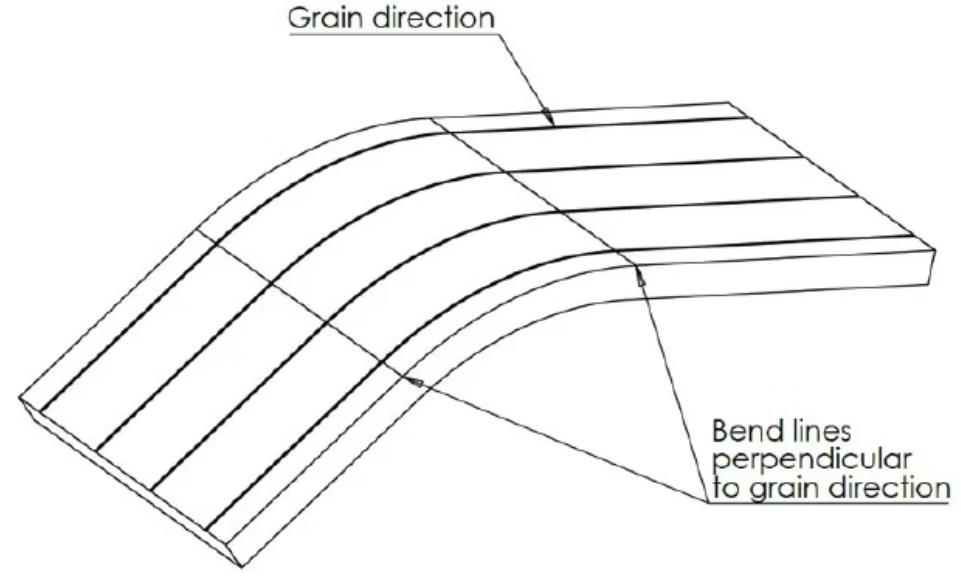

Bending stainless steel and other harder materials requires keener consideration of the grain direction. Bends for such materials should be designed to run against the grain.

Grain direction vs bend lines

Bend Height

The bend height is an equally critical metal stamping design consideration. This height should be at least 2.5 times the material thickness plus the bend radius. If it is less than 2.5T+R, post-processing requirements can be expensive.

Bend Relief Notch

A bend that is too close to a material’s edge can cause design challenges due to bend tears. Providing an offset is the first option, but if that is not feasible, the designer can add bend-relief notches.

Conclusion

Given the undying relevance of metal stamping parts, design is a core engineering practice that provides a solid foundation for other manufacturing processes. Since the entire journey is collaborative, there is no better way to ensure successful design and manufacture than to team up with the right company.

Metal stamping services should be defined by expertise, experience, and a provable portfolio. Get the best designs and stamped parts from a quality partner, and you will never regret it.