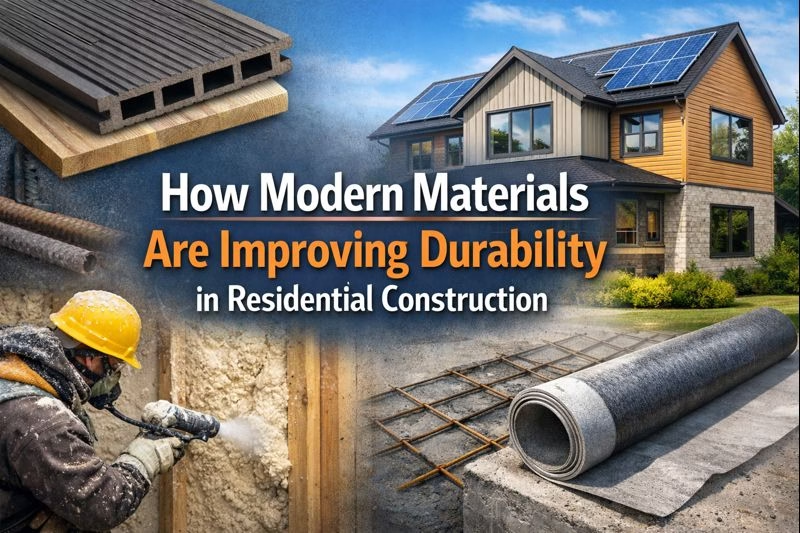

Residential construction has always been shaped by the materials available at the time. What has changed in recent decades is the pace of innovation. Today, builders and homeowners benefit from materials designed to last longer, perform better under stress, and adapt to changing environmental conditions. These advancements are reshaping how homes are built and maintained, leading to structures that age more gracefully and require fewer repairs over time. One example of this shift is the growing use of advanced bonding solutions such as MS Polymer Adhesives, which reflect a broader move toward flexible, resilient building systems rather than rigid, failure-prone ones.

The Meaning of Durability in Modern Homes

Durability in residential construction is no longer just about strength. It now includes resistance to moisture, temperature changes, movement, and long-term wear. Homes experience constant stress. Foundations settle, materials expand and contract with heat, and weather events place pressure on every surface. Traditional materials were often strong in one area but weak in others. For example, rigid materials might handle heavy loads but crack under movement.

Modern materials are designed with real-life conditions in mind. They are tested not only for strength but also for flexibility, longevity, and compatibility with other building components. This approach reduces failure points and extends the overall lifespan of a home.

Why Traditional Materials Fall Short

Older construction methods relied heavily on rigid connections and single-purpose materials. While effective at the time, many of these materials struggle in today’s environments. Increased humidity, extreme temperature swings, and more demanding energy efficiency standards expose their limitations.

Common issues with traditional materials include cracking due to structural movement, water penetration through small gaps, degradation from UV exposure, and loss of adhesion over time. Once these problems begin, they often spread. A small crack can allow moisture in, leading to rot, mold, or corrosion. Modern materials aim to prevent these chain reactions before they start.

Advances in Adhesives and Sealants

One of the most significant improvements in residential durability comes from advances in adhesives and sealants. Instead of relying solely on mechanical fasteners, builders now use high-performance bonding materials that distribute stress evenly and maintain their integrity over time. Many manufacturers, including VDB Adhesives, focus on developing solutions that balance strength with flexibility for modern building requirements.

Modern adhesives are formulated to remain elastic after curing. This flexibility allows them to absorb movement without cracking or separating. MS Polymer Adhesives, for instance, combine strong adhesion with long-term elasticity. They bond well to a variety of surfaces and continue performing even when materials shift slightly due to temperature changes or settling.

This flexibility is especially important in residential construction, where different materials meet. Wood, concrete, metal, and composites all expand and contract at different rates. A durable adhesive helps manage these differences and reduces stress at joints and seams.

Improved Resistance to Moisture and Weather

Water remains one of the biggest threats to residential durability. Modern materials are designed to manage moisture rather than simply block it. Breathable membranes, advanced sealants, and water-resistant composites work together to protect structures while allowing trapped moisture to escape.

Roofing systems, exterior cladding, and window installations now rely on layered protection. Instead of a single barrier, builders use multiple materials that each serve a specific role. Adhesives and sealants are critical in sealing gaps without becoming brittle over time, reducing the risk of leaks and long-term damage.

Stronger, Lighter Structural Materials

Another reason modern homes are more durable is the development of high-strength, lightweight materials. Engineered wood products, fiber-reinforced composites, and advanced concrete mixes offer better performance with less material.

These materials are manufactured for consistency. Unlike natural materials that can vary from piece to piece, engineered options provide predictable strength and behavior. This consistency reduces weak points and improves overall structural reliability. Lighter materials also place less stress on foundations, helping minimize settling and cracking over time.

Energy Efficiency and Durability Go Hand in Hand

Modern materials also support durability by improving energy efficiency. Insulation systems, airtight construction methods, and thermal breaks reduce temperature extremes within walls and roofs. Stable indoor conditions protect materials from repeated expansion and contraction, which is a common cause of deterioration.

Homes that maintain consistent temperatures experience less strain on structural components, finishes, and mechanical systems. Adhesives and sealants that retain their performance across temperature ranges play a key role in maintaining this balance.

Reduced Maintenance and Long-Term Value

One of the most practical benefits of modern construction materials is reduced maintenance. When materials resist cracking, moisture intrusion, and degradation, homeowners face fewer repairs and longer intervals between major upkeep.

Durable homes also support sustainability. Fewer repairs mean less material waste and lower resource consumption over time. By focusing on longevity and resilience, modern residential construction creates homes that deliver lasting value while adapting to real-world conditions.