When people talk about cutting costs in injection molding, the first thing they usually look at is material prices. Can we switch to a cheaper resin? Can we find a supplier with a lower rate? But here’s the truth most teams overlook: the single biggest lever on cost isn’t the resin you choose—it’s the design itself.

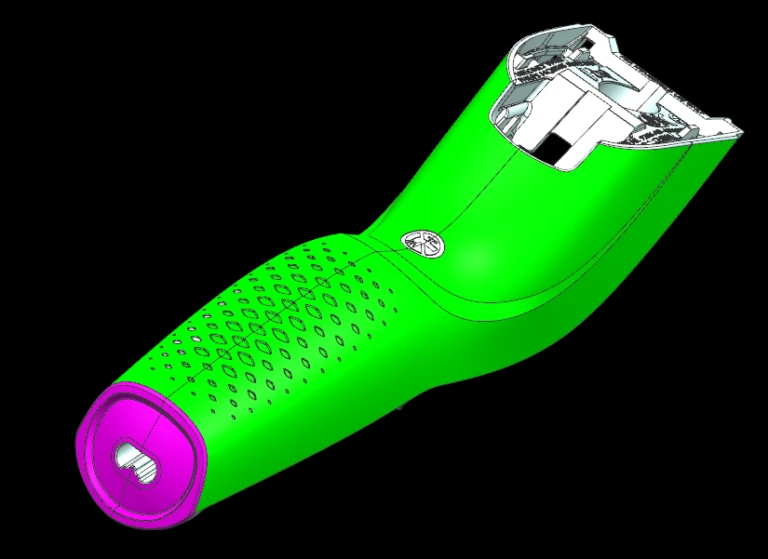

Think about it. A poorly designed part can force you into an expensive mold, eat up more resin than necessary, or stretch cycle times far beyond what’s reasonable. On the flip side, a smart design can make the mold simpler, reduce material waste, and keep production running faster and cleaner. That’s where the real savings are. And the best part? Those savings happen before a single part is molded—right at your CAD screen.

Cost Drivers in Injection Molding: Where the Money Really Goes

If you want to reduce costs, you first need to know where the money is actually going. In custom injection molding, the total expense isn’t just about the resin you buy. Three big cost buckets dominate the picture—and here’s how your design directly influences each of them.

1. Tooling and Mold Manufacturing

The mold is often the single largest upfront cost. Complexity, steel grade, and expected tool life all matter. A design full of deep undercuts or unnecessary side actions can push mold prices through the roof. On the other hand, a simpler, mold-friendly design means fewer moving parts, easier machining, and lower tooling bills.

2. Material Usage

Every gram of resin adds up, especially in high-volume runs. Wall thickness, part geometry, and the way you design runners and gates all determine how much material ends up in your parts—and how much gets wasted. Smart design trims excess resin without compromising performance, which is one of the fastest ways to save money.

3. Production Efficiency

Cycle time is king in molding. A part with uneven wall thickness might take longer to cool, stretching each cycle and lowering output. Poor draft angles slow ejection and increase tool wear. Even small inefficiencies here multiply quickly when you’re producing thousands—or millions—of parts.

Your design decisions ripple through all three of these cost drivers. Get it right early, and you’ll save on tooling, resin, and cycle time all at once. Get it wrong, and you’ll end up paying for it in every production run.

Smart Design Practice 1: Optimizing Wall Thickness

If there’s one design choice that quietly eats up cost in injection molding, it’s wall thickness. At first glance, you might think thicker walls mean stronger parts. In reality, uneven or oversized walls usually do the opposite—they drive up material use, slow down cycle times, and introduce defects like sink marks and warpage.

Here’s what smart wall thickness design looks like:

- Keep it uniform. Consistency is everything. When walls are even, parts cool more predictably, reducing stress and distortion.

- Avoid going too thick. Extra plastic doesn’t always add strength—it often just adds cost. Thicker sections take longer to cool, which stretches your cycle time and limits output.

- Use ribs and gussets instead. Need more stiffness? Add ribs or gussets instead of bulk. They reinforce the structure without bloating material usage.

Typical ranges you can aim for:

- Most commodity thermoplastics perform best with wall thickness between 2–4 mm.

- Thin-wall applications can go as low as 0.5–1 mm if the resin flows well (like PC or ABS).

- Thicker sections above 5 mm should be avoided unless absolutely necessary, as they almost always create shrinkage problems.

All in all, every extra millimeter of wall thickness increases both resin cost and cycle time. By designing walls with intention, you get stronger, lighter, and cheaper parts that run more reliably in production.

Smart Design Practice 2: Adding Proper Draft Angles

Draft angles often get ignored in the design stage. On screen, a vertical wall looks perfectly fine. But once you try to eject that part from the mold, it sticks like glue. The result? Scratch marks, cracked parts, and a mold that wears out faster than it should.

Adding draft isn’t complicated, but it makes a huge difference:

- Easier ejection. Even a small draft angle—1° to 2°—lets the part release smoothly, reducing stress on both the mold and the part.

- Lower tool wear. When parts don’t drag against the mold walls, your tooling lasts longer and needs less maintenance.

- Better surface finish. No more scuffed or distorted surfaces from aggressive ejection forces.

Pro tip: Don’t wait until the tooling stage to add draft. It’s much cheaper to apply it in CAD than to fix a mold that’s already been cut.

We’ve seen projects where simply adding 1.5° of draft eliminated weeks of delays and thousands in polishing costs. That’s the kind of small adjustment that pays off big.

Smart Design Practice 3: Simplifying Mold Features

One of the fastest ways to inflate your tooling bill is to overcomplicate the mold. Deep undercuts, thin unsupported ribs, or tricky side actions might look great in CAD, but every extra feature means more machining, more moving parts, and more opportunities for failure.

Here’s how simplifying features saves you money:

- Fewer side actions. Side pulls and lifters are expensive to build and maintain. If you can redesign a part to avoid them, your mold instantly becomes cheaper and more reliable.

- Shallower cores and cavities. Deep pockets increase machining time and may require special tooling. Reducing unnecessary depth lowers both manufacturing cost and cycle time.

- Stronger, simpler ribs. Ultra-thin ribs often lead to short shots or breakage. Making them slightly thicker—or eliminating unneeded ribs altogether—makes molding easier and reduces reject rates.

We once reviewed a design that used a sliding core just to create a small internal notch. By redesigning the part geometry, that slide became unnecessary—and the customer saved several thousand dollars in tooling cost on day one.

The fewer complex mechanisms your mold requires, the less you’ll spend upfront and the more reliable your production will be.

Smart Design Practice 4: Optimizing Gate and Runner Layout

You can have the perfect wall thickness and draft, but if the melt doesn’t flow properly into the mold, you’ll still end up with trouble. Gate and runner design often gets less attention than it deserves, yet it has a huge impact on both quality and cost.

Here’s why it matters:

- Balanced filling. Poor gate placement causes short shots, weld lines, or trapped air—all of which turn into scrap. A balanced flow ensures every cavity fills evenly, boosting your yield.

- Shorter cycle times. Optimized runners minimize pressure loss and allow faster, more efficient filling. That means less injection pressure, less energy, and smoother cycles.

- Lower material waste. Oversized or poorly designed runners eat up resin you can’t recover. Smart layout reduces waste without compromising flow.

We worked with a customer who had persistent weld line issues on a consumer product housing. By adjusting the gate position and resizing the runner system, the part filled more evenly. The result? Defects dropped, and the cycle time shrank by nearly 15%.

Gates and runners aren’t just “plumbing.” They dictate how efficiently your part gets made and how much resin ends up in the scrap bin. Treat them as a cost lever, not an afterthought.

Smart Design Practice 5: Choosing Materials with Cost and Performance in Mind

Material choice is one of the biggest cost levers in injection molding—and not just because of price per kilogram. The resin you select affects how easily parts fill, how much they shrink, and how many rejects you’ll end up scrapping. In other words, the wrong material doesn’t just cost more upfront, it costs more in wasted production.

Here’s what smart material strategy looks like:

- Pick resins that mold efficiently. A material with good flow characteristics can fill thinner walls with less pressure, cutting down on cycle times and reducing the risk of defects. For example, ABS and PP generally process more easily than high-viscosity resins.

- Watch shrinkage and warpage. Some materials shrink more than others, making it harder to hold tolerances. Matching resin properties to your design reduces rework and quality issues.

- Leverage regrind where possible. Many projects allow you to reprocess scrap runners and sprues back into the material stream. A thoughtful regrind strategy keeps resin costs down without sacrificing performance.

- Design for less waste. Gate and runner design isn’t the only factor—part geometry also matters. A compact design that uses less resin per shot keeps your material costs under control.

Pro tip: Don’t treat resin selection as purely a purchasing decision. Involve your manufacturing partner early, because they’ll know which materials balance cost, performance, and ease of molding.

Smart material choices mean fewer rejects, shorter cycle times, and lower resin bills. And when you’re running high-volume production, those savings multiply fast.

Common Design Mistakes That Drive Up Costs

Even with the best intentions, it’s easy to design a part that looks perfect on your screen but bleeds money in production. Here are a few pitfalls we see again and again—and how to steer clear of them.

1. Overbuilding with Excessive Thickness: It’s tempting to add material for “safety,” but thick walls don’t just use more resin—they extend cooling times and create sink marks. What you save in peace of mind, you lose in wasted resin and slower cycles.

Fix: Keep walls consistent and lean. Use ribs and gussets instead of bulk.

2. Designing with Unnecessary Complexity: Every extra slide, lifter, or deep undercut drives mold costs up. We’ve seen parts where a single decorative feature doubled the tooling bill. Unless that complexity adds real value, it’s not worth the price tag.

Fix: Simplify geometry where possible, and challenge whether each feature is truly needed.

3. Ignoring Draft and Tolerance Realities: Parts without draft angles or with overly tight tolerances don’t play nice with molds. You’ll pay for it in sticking parts, scratched surfaces, and endless rework.

Fix: Add reasonable draft (1–2° is often enough) and align tolerances with molding capabilities, not machining wish lists.

The truth is, none of these mistakes are hard to avoid—they just need to be caught early. That’s why a proper DfM review before you cut steel is worth its weight in gold. It’s far cheaper to tweak CAD than to rebuild a mold.

Partnering Early with Your Manufacturer

Some of the best savings come not from clever CAD tricks, but from collaborating with your manufacturing partner before the first tool is ever cut.

Because manufacturers see things you might miss. A wall that looks fine in CAD may be a cooling nightmare in production. A rib that feels sturdy could demand a costly slide in the mold. By looping in your partner during the design stage, you get practical feedback when changes are still cheap and easy to make.

How do they help?

Experienced suppliers use tools like mold-flow simulation to predict how resin will fill your part. They can flag risks like air traps, sink marks, or uneven cooling—problems that, if ignored, will cost you weeks of rework later. They’ll also review your design for manufacturability, pointing out ways to simplify features, reduce material usage, and speed up cycles.

That’s why working with an experienced plastic injection molding factory ensures cost savings are built into the design from day one. Instead of firefighting defects later, you’re preventing them before they exist.

Final Thoughts

At the end of the day, reducing injection molding costs isn’t about squeezing your supplier or switching to the cheapest resin. The real savings come from smart custom mold design. Every choice you make at the CAD stage—wall thickness, draft, gate placement, material selection—sets the stage for how much your part will cost and how smoothly it will run in production.

The companies that win are the ones who take design seriously, involve their manufacturing partners early, and build cost savings into the product before the first mold is even cut. That’s how you avoid costly mistakes, shorten lead times, and get parts that perform without constant firefighting.

So here’s the challenge for your next project: don’t wait until the mold is already built to start thinking about cost. Start at the design stage, apply these smart practices, and partner with experts who can spot risks before they become problems. You’ll thank yourself later when your product launches on time, on budget, and with fewer surprises.