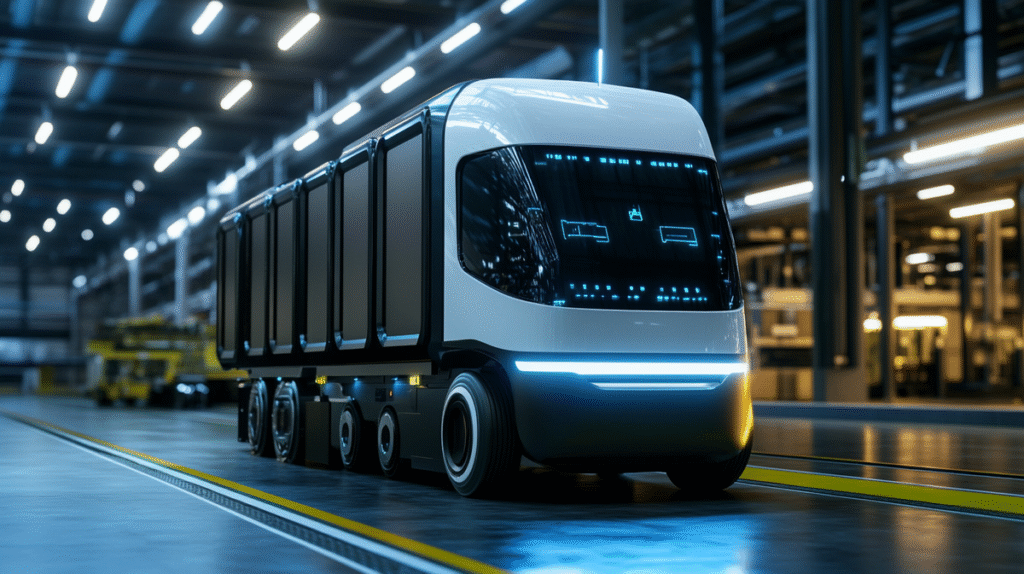

In the rapidly evolving landscape of industrial automation, Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are at the forefront of transforming production processes and enhancing factory logistics. These advanced technologies are not only reshaping how goods are moved within manufacturing facilities but are also setting new standards for efficiency, safety, and flexibility. As industries strive to meet the demands of a global market, the integration of AGV/AMR systems is becoming increasingly crucial. This article delves into the pivotal role these autonomous vehicles play in modern manufacturing, exploring their impact on production processes and logistics, and highlighting the benefits they bring to the table.

The Role of Autonomous Vehicles in Transforming Production Processes

Autonomous vehicles, specifically AGVs and AMRs, are revolutionizing production processes by automating the transportation of materials and products within manufacturing facilities. This automation leads to significant improvements in efficiency and productivity. Unlike traditional conveyor systems, AGVs and AMRs offer flexibility and scalability, allowing manufacturers to adapt quickly to changes in production demands.

AGVs are typically used for repetitive tasks such as transporting raw materials to production lines or moving finished products to storage areas. They follow predefined paths and are equipped with sensors to avoid obstacles, ensuring safe and reliable operations. On the other hand, AMRs are more advanced, capable of navigating dynamic environments without the need for fixed paths. This adaptability makes them ideal for complex manufacturing settings where layout changes are frequent.

The integration of AGV/AMR systems for automated processes allows manufacturers to optimize their workflows, reduce labor costs, and minimize human error. By automating material handling, companies can focus their workforce on more value-added tasks, enhancing overall productivity and competitiveness.

Improving Factory Logistics with AGV/AMR Technology

Factory logistics is a critical component of manufacturing operations, and AGV/AMR technology plays a vital role in streamlining these processes. Efficient logistics ensure that materials and products are delivered to the right place at the right time, reducing bottlenecks and downtime. AGVs and AMRs contribute to this efficiency by providing reliable and consistent material transport.

One of the key advantages of using AGVs and AMRs in logistics is their ability to operate 24/7 without fatigue, unlike human workers. This capability ensures continuous operations, which is particularly beneficial in industries with high production volumes. Additionally, these autonomous vehicles can be integrated with warehouse management systems, enabling real-time tracking and inventory management.

Moreover, AGVs and AMRs enhance safety within factories by reducing the risk of accidents associated with manual material handling. Their advanced sensors and navigation systems allow them to detect and avoid obstacles, ensuring safe interactions with human workers and other machinery. This safety aspect is crucial in maintaining a secure working environment and complying with industry regulations.

Future Prospects and Challenges of AGV/AMR Integration

As the adoption of AGV/AMR technology continues to grow, the future prospects for these autonomous vehicles in manufacturing are promising. Advances in artificial intelligence and machine learning are expected to further enhance their capabilities, enabling more sophisticated decision-making and problem-solving abilities. This evolution will likely lead to even greater efficiencies and cost savings for manufacturers.

However, the integration of AGVs and AMRs is not without challenges. One of the primary concerns is the initial investment cost, which can be significant for small and medium-sized enterprises. Additionally, the implementation of these systems requires careful planning and coordination to ensure seamless integration with existing processes and infrastructure.

Despite these challenges, the benefits of AGV/AMR technology far outweigh the drawbacks. As industries continue to embrace automation, the role of autonomous vehicles in manufacturing will undoubtedly expand, driving innovation and growth in the sector.