In the fast-moving world of manufacturing, efficiently and cost-effectively meeting market demand involves high-volume production. Industries such as automotive, aerospace, and electronics rely on precision and rapid production to continuously deliver quality products. This process heavily relies on metal stamping parts manufacturers who produce complex, high-volume parts with stamping molds which are literally the foundation of these operations.

This article explains the importance of stamping molds in high-volume production, the advantages of working with reputable metal stamping parts manufacturers, and how these molds enable efficient, precise, and scalable manufacturing. As industries shift towards the production of more intricate and customizable parts, stamping molds guarantee quality and production speed at a lower cost.

The Basics of Stamping Molds and Their Importance

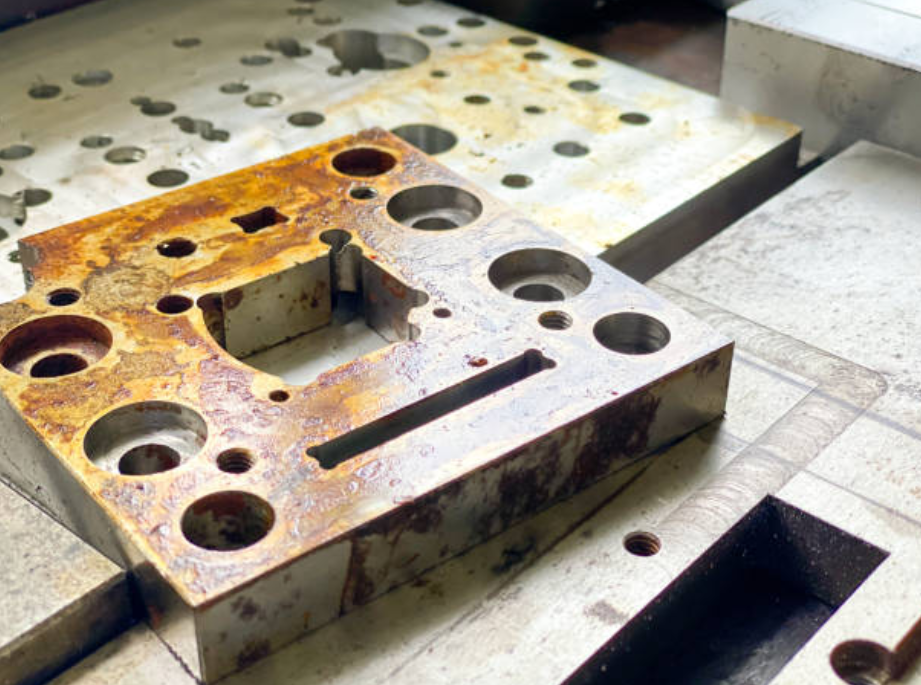

They are tools used in the metal stamping process to shape flat metal sheets into specific shapes and sizes. These molds are essential for ensuring that the produced parts meet the required specifications in terms of shape, dimensions, and surface finish. The quality of the stamping mold directly affects the accuracy and consistency of the parts produced, which is why selecting the right metal stamping parts manufacturers is crucial for high-volume production.

In high-volume manufacturing, they are often designed to be highly durable, capable of handling thousands or even millions of cycles without significant wear. This durability ensures that production remains consistent over long periods, reducing the need for frequent mold changes and minimizing production downtime. Whether used for creating automotive parts, consumer electronics components, or industrial machinery components, they are vital in maintaining a high level of efficiency and precision throughout the manufacturing process. Their effectiveness ensures that mass production can be both efficient and sustainable, maintaining high standards in large-scale operations.

Efficiency in High-Volume Production: The Role of Stamping Molds

For large-scale production, time and cost efficiency are critical. The manufacturers of stamped metal parts make use of stamping dies to mass produce parts quickly and cost effectively. The automation of the stamping process allows for rapid cycling as well as manufacturing processes with little to no distinguishable difference between parts. This is very important in industries where mass production is needed and a certain level of quality and performance is still expected.

Using stamping dies, manufacturers are able to provide parts with superior quality in an extremely reduced time frame as compared to the traditional methods. The creation of accurate and uniform parts at an astounding rate aids in meeting strict production schedules and lowering costs. This level of efficacy is conferred particularly useful in industries such as automotive where components need to be manufactured quickly and in bulk to match the production lines. In addition, the adoption of stamping dies contributes to better use of materials, thus minimizing wastage and cutting down the overall cost of production even more. Too, automating and using accuracy tools can minimize manual mistakes and increase productivity greatly, therefore increasing the competitiveness of the economy.

Quality Control and Consistency in Production

Having stamping molds for high production runs is beneficial for maintaining quality due to consistency. To guarantee that every part produced matches the specific requirements, metal stamping parts manufacturers spend lots of money on expensive quality control systems. From the design and prototyping stage down to mass production, they are checked for every single run of production to ensure there is no variation for every single production run.

Maintaining tight tolerances for precision parts requires the molds to be built to endure the strain of continuous use. Periodic checking on the molds eliminates any suspected problems such as wear and tear, and misalignment which ensures any issues are solved instantly, This enhances production efficiency by minimizing downtime. In fields that require such precision like aerospace, automotive, and medical device construction, accuracy in every single part is crucial to ensure they are safe, function properly, and obey regulations. Costly defects are lessened with consistent high output, which help manufacturers profit in the long run.

The Benefits of Partnering with Experienced Metal Stamping Parts Manufacturers

For businesses looking to incorporate stamping molds into their high-volume production, partnering with experienced metal stamping parts manufacturers offers numerous benefits. First and foremost, an established manufacturer has the expertise to design and build molds that will produce parts efficiently and consistently, even under demanding production conditions.

A reliable metal stamping parts manufacturer can also help optimize the stamping process by recommending the best materials for the job, ensuring that the parts meet performance standards while remaining cost-effective. Furthermore, these manufacturers can provide ongoing support, including mold maintenance, troubleshooting, and design adjustments, ensuring that the production process remains smooth and uninterrupted. This partnership allows companies to have access to the latest technologies and materials, ensuring their products remain at the forefront of innovation.

Additionally, working with an experienced manufacturer helps businesses stay competitive by offering faster time-to-market and the ability to scale production quickly. With the right stamping molds and a trusted manufacturing partner, businesses can meet customer demands faster while maintaining high quality and minimizing costs. This strategic partnership not only provides reliable production but also fosters the growth and development of a company by ensuring continuous support throughout the product life cycle.

Conclusion

Industries such as automotive, aerospace, medical devices, and electronics heavily rely on Stamping molds for high-volume production. These molds are critical for achieving excellence in quality and precision while minimizing production costs and waste. A proficient metal stamping parts manufacturer becomes essential for businesses wanting to optimize their efficiency for design and production integration.

Experts in the business environment suches as these metal stamping parts manufacturers must guarantee control of the quality provided and guarantee faster time providers that specialize in forging molds enables design customization and flexible alteration of parts. Achieving the most optimal results is possible when businesses get these high precision tools fully meeting their parts and delivery schedule at the anticipated budget. The succession of your production and supply mobilization is highly reliant on the advantages provided by these experts hence the vast amount of money that will be saved.