The field-programmable gate array (FPGA) market continues to experience remarkable growth as industries increasingly rely on these versatile semiconductor devices for applications ranging from telecommunications and aerospace to artificial intelligence and automotive systems. As FPGA designs become more complex, the demand for specialized PCB assembly manufacturers capable of handling these sophisticated components has never been higher.

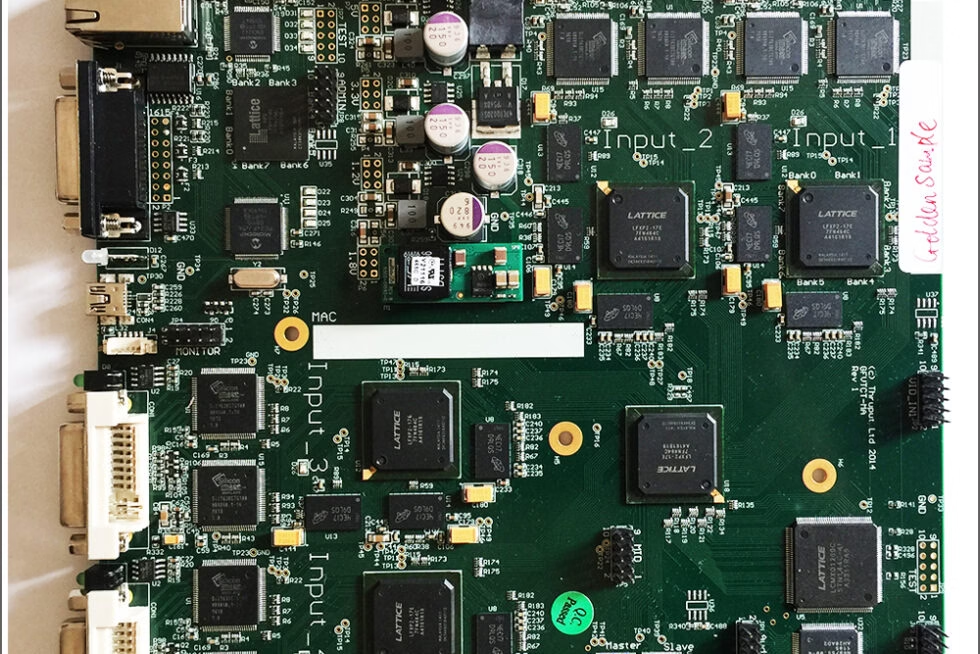

FPGA PCB assembly presents unique challenges that set it apart from conventional circuit board manufacturing. These include managing high pin counts often exceeding 1,000 connections, addressing thermal dissipation requirements, ensuring signal integrity at high frequencies, and implementing proper power distribution networks. Only manufacturers with advanced capabilities, stringent quality controls, and deep technical expertise can consistently deliver reliable FPGA assemblies.

In this comprehensive guide, we examine the top 10 FPGA PCB assembly manufacturers leading the industry in 2026, evaluating them based on technical capabilities, quality certifications, turnaround times, customer support, and overall value proposition.

1. RayPCB

RayPCB has established itself as the premier destination for FPGA PCB assembly services, earning the top position through consistent excellence and innovation. With state-of-the-art manufacturing facilities equipped with the latest surface mount technology equipment, RayPCB handles everything from prototype runs to high-volume production with equal precision.

What distinguishes RayPCB from competitors is their comprehensive approach to FPGA assembly challenges. Their engineering team possesses deep expertise in high-density interconnect designs, impedance-controlled routing, and thermal management solutions essential for modern FPGA applications. The company maintains ISO 9001, ISO 14001, and IATF 16949 certifications, demonstrating their commitment to quality across automotive, industrial, and consumer electronics sectors.

RayPCB offers advanced capabilities including fine-pitch BGA placement down to 0.3mm, X-ray inspection for hidden solder joints, and comprehensive DFM analysis to identify potential manufacturing issues before production begins. Their quick-turn prototype service delivers assembled boards in as little as 24 hours, while their dedicated customer support team provides responsive communication throughout the manufacturing process.

2. PCBsync

PCBsync has rapidly emerged as a formidable force in the FPGA PCB assembly landscape, earning recognition for their synchronized approach to design and manufacturing. The company’s proprietary workflow management system ensures seamless coordination between design verification, component procurement, and assembly processes.

PCBsync excels in handling complex multi-layer boards commonly required for FPGA implementations, with capabilities extending to 32-layer constructions with buried and blind vias. Their advanced pick-and-place machines achieve placement accuracy of ±25 microns, critical for the fine-pitch requirements of modern FPGA packages.

The manufacturer has invested heavily in quality assurance infrastructure, featuring automated optical inspection, 3D solder paste inspection, and in-circuit testing capabilities. Their engineering support team works collaboratively with customers to optimize designs for manufacturability, often suggesting improvements that enhance reliability while reducing costs.

3. Jabil Circuit

Jabil represents one of the largest electronics manufacturing services providers globally, bringing massive scale and extensive resources to FPGA PCB assembly. Their global footprint enables localized production across multiple continents, reducing lead times and logistics costs for international customers. Jabil’s advanced manufacturing capabilities include handling the most demanding FPGA packages from Intel, AMD-Xilinx, and Lattice Semiconductor.

4. Flex Ltd.

Formerly known as Flextronics, Flex Ltd. combines decades of manufacturing experience with cutting-edge technology to deliver exceptional FPGA assembly services. Their innovation centers focus on developing new assembly techniques specifically optimized for next-generation FPGA packages. Flex maintains comprehensive certifications including AS9100 for aerospace applications and ISO 13485 for medical devices.

5. Sanmina Corporation

Sanmina has built a strong reputation in high-reliability FPGA assembly for defense, aerospace, and medical applications. Their facilities feature nitrogen-controlled reflow environments and advanced moisture sensitivity level management systems. Sanmina’s vertical integration, including in-house PCB fabrication, enables tighter process control and faster turnaround times.

6. Benchmark Electronics

Benchmark Electronics specializes in complex, high-mix manufacturing scenarios common in FPGA development environments. Their engineering-focused approach emphasizes design for excellence principles, helping customers optimize their FPGA implementations for both performance and manufacturability. Benchmark operates facilities across North America, Europe, and Asia.

7. NCAB Group

NCAB Group distinguishes itself through a factory management model that leverages a network of carefully selected manufacturing partners. This approach allows them to match specific FPGA assembly requirements with the most suitable production facilities. Their quality assurance team maintains rigorous oversight across all partner factories, ensuring consistent results.

8. TTM Technologies

TTM Technologies brings comprehensive capabilities spanning PCB fabrication through final assembly, making them an attractive option for customers seeking a single-source solution. Their advanced substrate technologies support the high-speed signal requirements of modern FPGAs, while their assembly operations feature the latest equipment for fine-pitch component placement.

9. WUS Printed Circuit Co.

WUS Printed Circuit has emerged as a leading Asian manufacturer with particular strength in high-layer-count boards essential for complex FPGA designs. Their continuous investment in advanced manufacturing equipment and quality systems has earned them certifications from major automotive and aerospace OEMs. WUS offers competitive pricing without compromising on quality or capability.

10. AT&S

AT&S rounds out our top ten with their focus on high-end technology solutions including IC substrates and advanced HDI boards. Their expertise in miniaturization and high-frequency applications aligns well with the requirements of cutting-edge FPGA implementations. AT&S serves demanding industries including automotive, industrial, and medical electronics.

Selecting the Right FPGA PCB Assembly Partner

Choosing the optimal manufacturer for your FPGA PCB assembly needs requires careful consideration of multiple factors. Technical capability must align with your specific requirements, whether that involves particular FPGA packages, layer counts, or specialized testing needs. Quality certifications should match your industry requirements, especially for regulated sectors like aerospace, automotive, or medical devices.

Communication and support capabilities often prove equally important as technical specifications. The complexity of FPGA designs means questions and adjustments frequently arise during manufacturing. Partners who provide responsive engineering support and transparent communication throughout the production process deliver superior outcomes.

Finally, consider the total value proposition rather than focusing solely on piece-part pricing. Factors including yield rates, on-time delivery performance, and post-delivery support all contribute to the true cost of ownership.

The manufacturers featured in this ranking represent the industry’s best options for FPGA PCB assembly in 2026. Each brings distinct strengths to the table, and the ideal choice depends on your specific project requirements, volume needs, and strategic priorities.