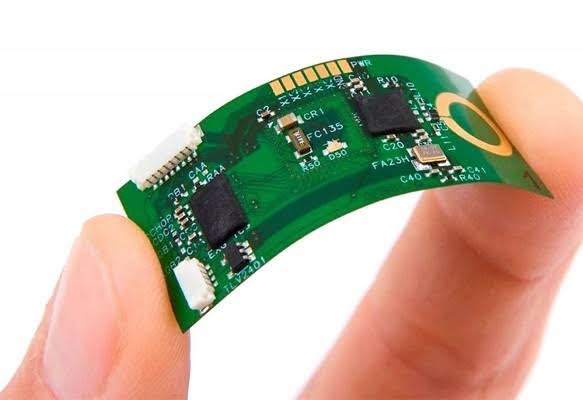

Flexible printed circuit boards (PCBs) are transforming the landscape of modern electronics, offering versatility and innovation across various industries. With the rise of wearable technology, automotive advancements, and the Internet of Things, the demand for flexible PCBs is surging. Flexible PCB designs allow for increased adaptability, making them ideal for compact and dynamic applications. This article explores the key sectors fueling this growth and highlights why understanding these trends is essential for businesses and consumers alike.

Overview of Flexible PCBs

Flexible printed circuit boards (PCBs) are essential components in modern electronics, known for their adaptability and space-saving benefits. These boards consist of thin, flexible substrates allowing intricate designs, which enable them to fit into tight spaces within various devices.

Flexible PCBs support numerous applications across diverse industries. Their lightweight nature and high density promote efficiency in wearable technology, such as smartwatches and fitness trackers. In the automotive sector, flexible PCBs improve functionality in advanced driver-assistance systems and infotainment solutions.

Additionally, the Internet of Things (IoT) significantly drives the demand for flexible PCBs. These boards facilitate connections among smart devices, contributing to seamless communication and improved automation. As industries seek innovative solutions for compact and efficient designs, flexible PCBs play a crucial role in meeting these objectives.

The evolving landscape of consumer electronics further solidifies the relevance of flexible PCBs. Devices requiring wireless and compact components rely heavily on these boards for their performance. The growing trend of miniaturization in electronics emphasizes the importance of flexible PCBs as foundational elements in modern designs.

Key Industries Driving Demand

Several key industries are increasing the demand for flexible printed circuit boards (PCBs). These sectors use the advantages of flexible PCBs for innovative applications, making them integral to their growth.

Consumer Electronics

Consumer electronics represent a significant market for flexible PCBs, driven by the demand for compact and lightweight devices. Smartphones, tablets, smartwatches, and fitness trackers require thin and flexible designs to accommodate advanced features. Flexible PCBs improve durability and provide efficient electrical connections, enabling seamless performance in these devices.

Automotive Industry

The automotive industry is rapidly adopting flexible PCBs, especially in advanced driver-assistance systems (ADAS) and infotainment solutions. Flexible PCBs enable the integration of multiple functions within limited space, catering to modern vehicle needs for connectivity and safety. Increased automation and the shift toward electric vehicles further propel demand, as manufacturers seek reliable, lightweight solutions for complex electronic systems.

Medical Devices

Medical devices benefit from the adaptability of flexible PCBs, making them crucial in wearable health monitors, diagnostic equipment, and implantable devices. Their conformability allows for unique designs that fit snugly on the body, enhancing patient comfort. Additionally, flexible PCBs support miniaturization, which is vital for developing portable medical technologies that improve patient care and monitoring.

Aerospace and Defense

The aerospace and defense sectors rely on flexible PCBs for critical applications where space and weight savings are paramount. These PCBs support systems such as avionics, radar, and communication devices. Their ability to withstand extreme conditions while maintaining performance boosts their appeal in this industry, where reliability is essential.

Factors Contributing to Demand

The demand for flexible printed circuit boards (PCBs) is influenced by several key factors that align with industry trends and technological needs.

Technological Advancements

Technological advancements play a significant role in increasing the demand for flexible PCBs. Innovations in electronics, such as miniaturization and enhanced connectivity, require components that offer high performance in compact spaces. Flexible PCBs facilitate sophisticated device features while conserving space, becoming crucial in sectors like consumer electronics, automotive systems, and medical instruments. Enhanced manufacturing techniques also contribute to improved reliability and functionality, making flexible PCBs indispensable in modern applications.

Cost-Effectiveness

Cost-effectiveness serves as another driving force behind the growth of flexible PCBs. The ability to produce lightweight and durable designs streamlines manufacturing processes and reduces material costs. Flexible PCBs often lead to lower overall production costs due to their efficiency and versatility. Businesses recognize that integrating flexible PCBs into their products can yield better long-term savings while improving performance.

Design Flexibility

Design flexibility emerges as a critical factor influencing demand for flexible PCBs. Their adaptable nature allows for intricate designs that traditional rigid PCBs cannot accommodate. Industries can implement unique configurations to fit specific applications, supporting innovation in product development. This capability encourages companies to investigate new device designs that improve user experience and operational efficiency. As industries demand more customized solutions, the reliance on flexible PCBs continues to grow.

Conclusion

The demand for flexible PCBs is poised for significant growth as industries continue to innovate and adapt to modern technological needs. Their unique advantages cater to the requirements of consumer electronics automotive medical devices and aerospace sectors. As the push for compact lightweight and high-performance solutions intensifies flexible PCBs will play a crucial role in shaping the future of electronics. With advancements in manufacturing techniques and an increasing focus on sustainability the landscape for flexible PCBs is evolving rapidly. This evolution not only enhances device functionality but also drives the development of new applications across various markets.

Frequently Asked QuestionsWhat are flexible printed circuit boards (PCBs)?

Flexible printed circuit boards (PCBs) are thin, flexible substrates that allow for intricate and adaptable designs in electronic devices. They are lighter and can fit into compact spaces, making them essential in various industries like consumer electronics, automotive, medical, and aerospace.

Why is the demand for flexible PCBs increasing?

The demand for flexible PCBs is increasing due to the growth of wearable technology, advancements in automotive systems, and the expansion of the Internet of Things (IoT). These applications require lightweight, high-density designs that enhance device performance and connectivity.