In laboratories and industrial settings, precision and reliability are critical when handling liquids. Whether for medical applications, chemical processing, or food production, the need for accurate, contamination-free fluid transfer is paramount. This is where peristaltic pumps come into play. Thermoline Scientific, a trusted name in laboratory and medical equipment in Australia, offers a high-quality range of peristaltic pumps designed to deliver consistent performance and precise control. In this article, we’ll explore the benefits of peristaltic pumps and why Thermoline’s models are the ideal solution for demanding applications.

1. What is a Peristaltic Pump and How Does It Work?

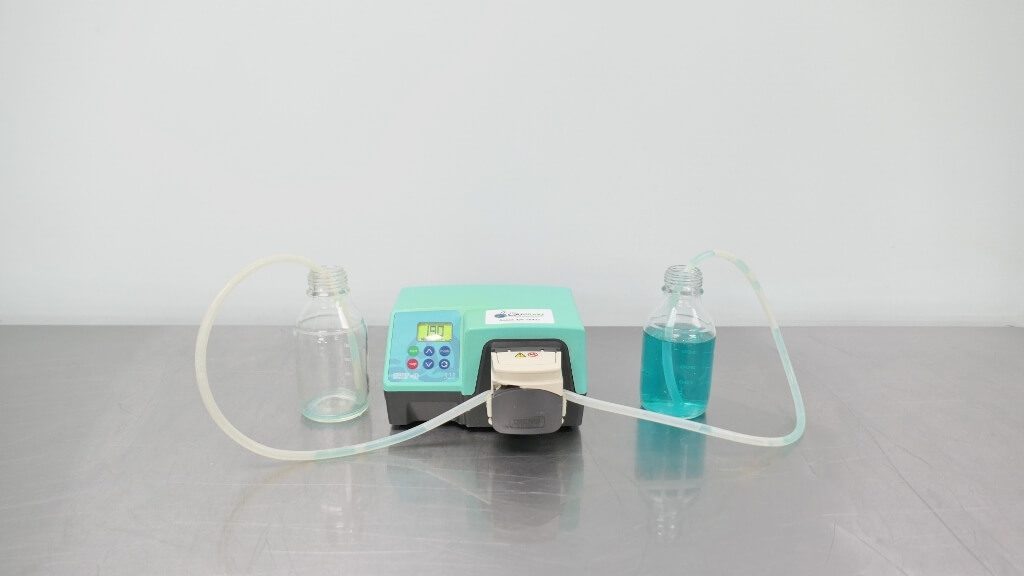

A peristaltic pump is a type of positive displacement pump used to move liquids through a flexible tube using a series of rotating rollers. The pump works by compressing a flexible tube, usually made of silicone or similar material, as the rollers rotate along the length of the tube.

The compression creates a seal that pushes the liquid forward while the rollers maintain continuous flow. As the roller moves away from the tube, the tube expands back to its original shape, creating suction that draws more fluid into the system. This process allows for precise control over flow rate and prevents contamination since the liquid only contacts the interior of the tube, not the pump mechanism itself.

2. Why Peristaltic Pumps are Ideal for Precise Fluid Handling

🎯 High Accuracy and Precision

Peristaltic pumps can deliver very specific volumes of liquid with minimal variation. Thermoline’s pumps offer stable flow rates and the ability to adjust the dispensing volume accurately, making them ideal for applications requiring consistent results.

🛡️ Contamination-Free Operation

Since the liquid only comes into contact with the tube and not the pump components, the risk of cross-contamination is eliminated. This makes peristaltic pumps particularly well-suited for medical, pharmaceutical, and food industry applications where hygiene is essential. For large quantities of fluid, stainless steel drum pumps are the most recommended, especially in the pharmaceutical and food industries. Their corrosion-resistant material ensures durability and reliability, making them ideal for handling bulk liquids while maintaining strict hygiene standards in these sensitive sectors.

🔄 Easy Maintenance and Cleaning

Replacing the tubing is simple and cost-effective. If the tubing becomes worn or contaminated, it can be quickly swapped out without disassembling the pump, reducing downtime and maintenance costs.

🔧 Versatility Across Applications

Peristaltic pumps can handle a wide range of fluids, including:

✔️ Corrosive chemicals

✔️ Viscous solutions

✔️ Suspensions and slurries

✔️ Biological fluids

✔️ Clean water and beverages

The ability to transfer liquids of varying viscosities without altering performance makes peristaltic pumps a versatile choice for multiple industries.

3. Thermoline’s Range of Peristaltic Pumps

Thermoline offers an extensive range of peristaltic pumps designed for different applications and flow rates. Each model is engineered to provide consistent performance and ease of use.

✅ Micro K Series Peristaltic Pump (LABK3)

- Compact design suitable for limited spaces

- Stable flow rate of up to 149 ml/min

- Speed range: 0.1 – 350 rpm

- Ideal for continuous dosing applications

✅ Mini S Series Peristaltic Pump (LABS3)

- Larger flow capacity with a stable flow rate of up to 930 ml/min

- Speed range: 0.1 – 350 rpm

- Compact and lightweight design

- Suitable for continuous dosing in laboratories and industrial settings

✅ Compact Q Series Peristaltic Pump (LABQ)

- Flow rate of up to 326 ml/min

- Speed range: 0.1 – 350 rpm

- Ideal for small-scale laboratory work

- Compact and easy to operate

✅ Dispensing Peristaltic Pump (LABF)

- Designed for automated dispensing applications

- Flow rate of up to 2280 ml/min

- Speed range: 0.1 – 600 rpm

- User-controlled dispensing action with preset volume, pause, and count times

- Excellent for medical and pharmaceutical settings

✅ Handypump Stainless Steel Peristaltic Pump (SK-HANDYPUMP)

- 304 stainless steel construction for maximum durability

- Flow rate of up to 365 ml/min

- Speed range: 0.1 – 300 rpm

- OLED screen displays motor speed and working status

- Available with single or dual pump head options

4. Benefits of Thermoline Peristaltic Pumps

🌡️ Consistent Performance Across Conditions

Thermoline pumps are engineered to maintain a stable flow rate even when handling high-viscosity or abrasive fluids. This ensures consistent results, even in challenging environments.

🔋 Energy Efficient and Cost Effective

Thermoline pumps are designed for low power consumption, making them energy efficient while maintaining high performance. This reduces operational costs without sacrificing reliability.

🏆 Built for Long-Term Use

High-quality materials, including stainless steel and durable tubing, ensure that Thermoline’s pumps withstand long-term use without degradation. The ability to replace tubing without overhauling the pump further enhances longevity.

5. Common Applications of Peristaltic Pumps

Thermoline’s peristaltic pumps are widely used across multiple industries due to their precision and reliability:

- Medical and Pharmaceutical – Accurate dosing and sterile fluid handling

- Laboratories – Mixing, dispensing, and transferring solutions

- Food and Beverage – Handling food-safe liquids without contamination

- Chemical Processing – Transferring and mixing reactive chemicals

- Water Treatment – Precise dosing of chemicals for purification

6. Why Thermoline is the Right Choice for Peristaltic Pumps

Thermoline’s reputation for quality and performance makes them a trusted name in laboratory and industrial equipment. Here’s why their peristaltic pumps stand out:

👉 Comprehensive Product Range – Models suitable for small-scale labs and large-scale industrial applications.

👉 User-Friendly Design – Intuitive controls and clear displays for ease of use.

👉 Precision and Accuracy – Stable flow rates and adjustable speeds for tailored performance.

👉 Reliable Customer Support – Thermoline’s expert team provides guidance and support for product selection and maintenance.

👉 Australian-Made Quality – Manufactured to meet stringent industry standards.

7. How to Choose the Right Peristaltic Pump

When selecting a peristaltic pump for your application, consider the following factors:

✔️ Flow Rate – Choose a model that matches the volume and speed requirements of your operation.

✔️ Chemical Compatibility – Ensure the tubing material is suitable for the liquid being transferred.

✔️ Automation Needs – Select a model with automated dispensing features if needed.

✔️ Construction Material – Stainless steel models are ideal for sterile and industrial environments.

8. Precision and Performance with Thermoline Peristaltic Pumps

Peristaltic pumps offer a reliable and efficient solution for fluid transfer and dosing in demanding environments. Thermoline’s range of peristaltic pumps delivers unmatched precision, ease of use, and long-term reliability, making them a valuable addition to any laboratory or industrial facility.

With a wide selection of models, precise flow control, and robust construction, Thermoline’s peristaltic pumps are designed to handle even the most challenging applications with ease.

Discover Thermoline’s full range of peristaltic pumps today and experience the precision and reliability your operation deserves.